Process for reclaiming methacrylic acid from a high-boiler phase and an aqueous phase

A technology of methacrylic acid and compound phase, applied in the field of high boiling point compound phase and water phase recovery of methacrylic acid, can solve the problems such as not teaching recovery of methacrylic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

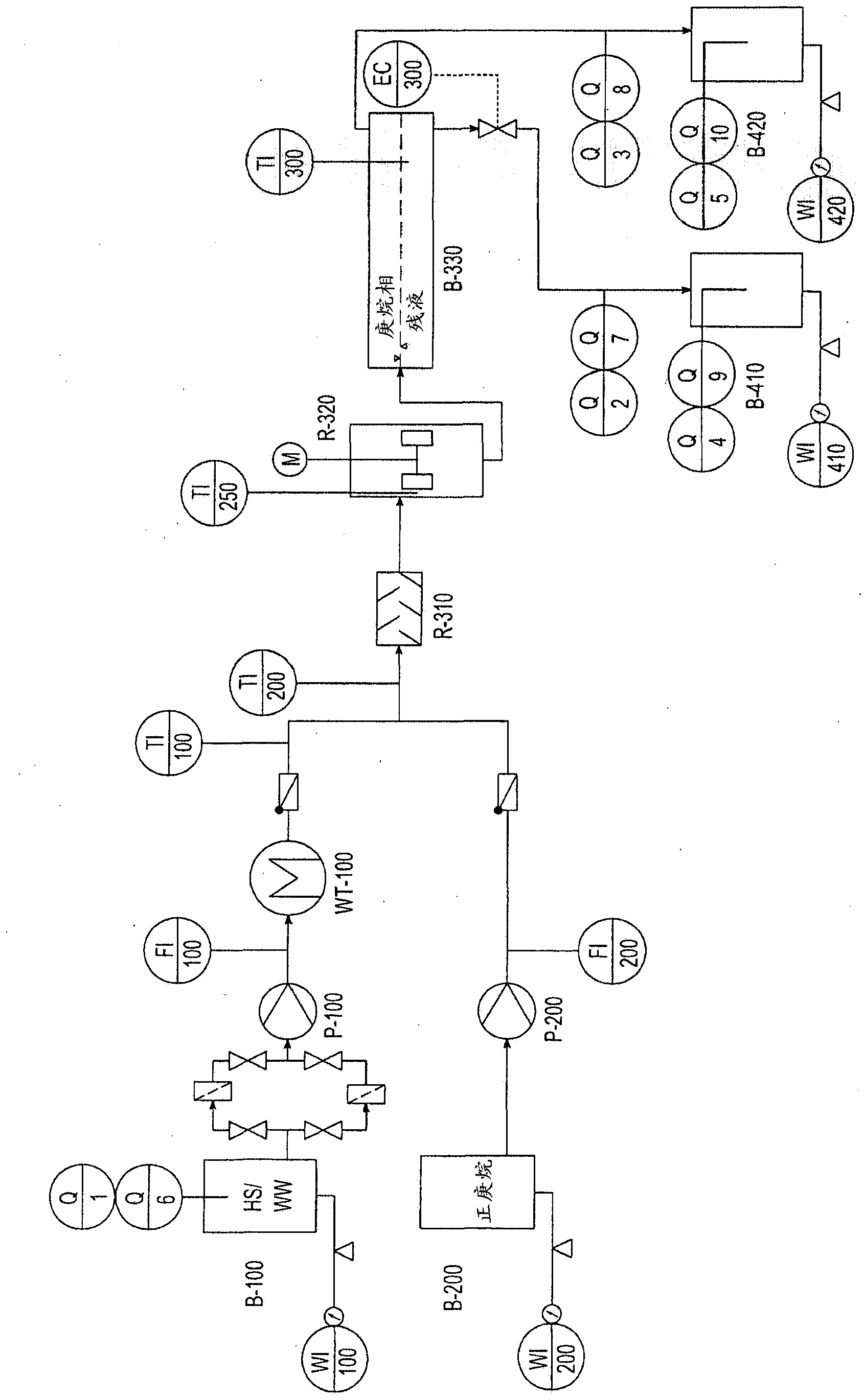

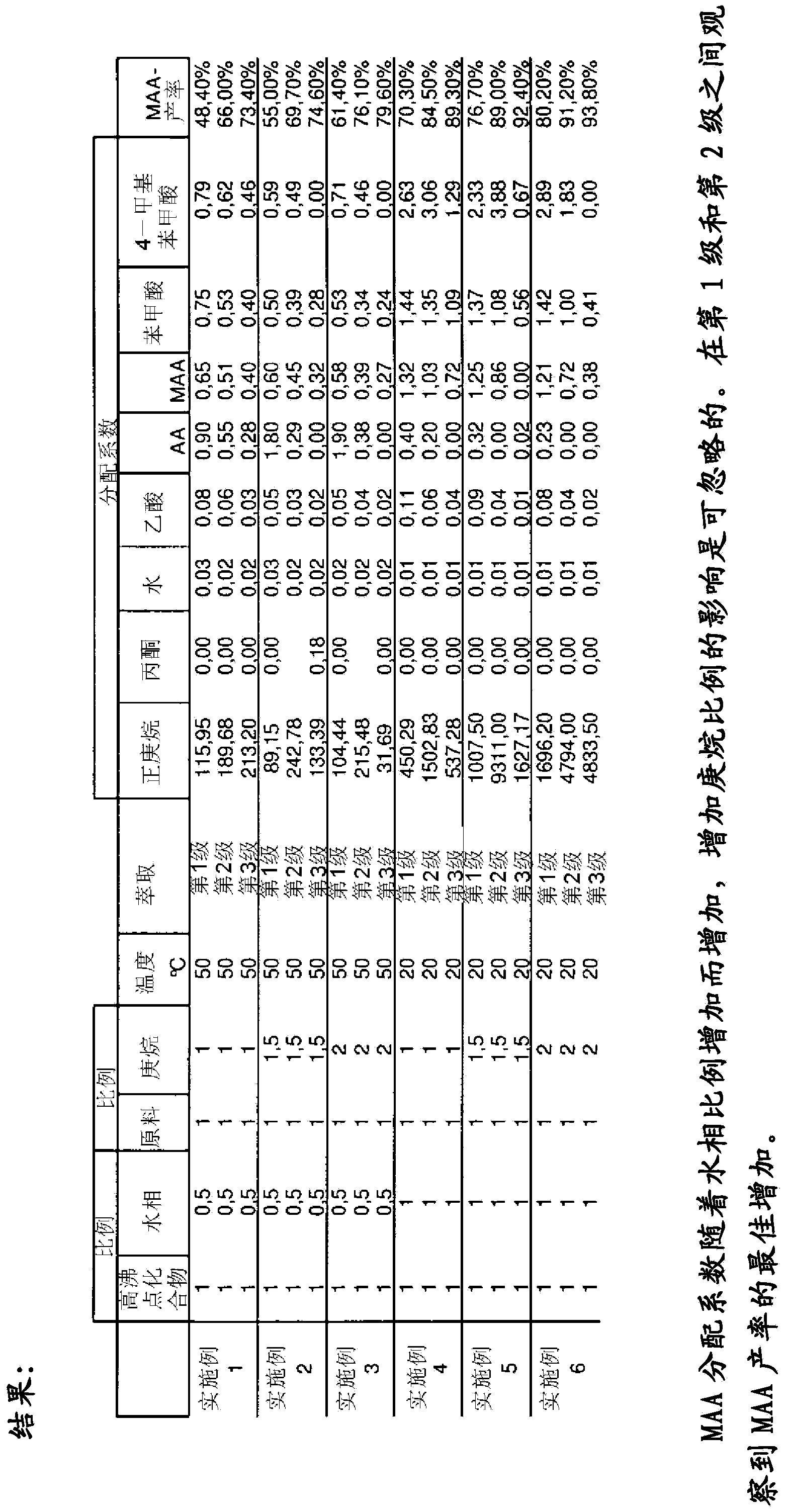

[0050] in accordance with figure 1 Examples 1-6 were carried out in the device. The high boiler and aqueous phases in different proportions were combined and passed through a paper filter. The filtrate was used as feedstock to a continuous mixer-settler unit. The feedstock was preheated in heat exchanger WT-100, mixed with different amounts of n-heptane (see table of results) as extraction medium and passed through static mixer R-310. In the mixer R-320 an intensive mixing of the high boilers / water phase and n-heptane is achieved, while in the settler B-330 the phases are separated. When equilibrium is reached, analytical samples are extracted at points Q1-Q3 and at the end of the run at Q4-Q6. Because this continuous experimental setup only achieved one separation step, each run was performed long enough (approximately 16 h) to collect enough material for the next extraction step. The mixer-settler unit was run in cross-flow mode only.

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com