Flexible glue-free copper-clad plate and manufacturing method thereof

A copper-clad laminate and flexible technology, which is applied in the field of flexible non-adhesive copper-clad laminate and its preparation, can solve the problems of consistent expansion coefficient of copper foil, poor heat resistance, high bonding strength, etc., achieve satisfactory bonding strength and achieve dimensional stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention discloses a method for preparing a flexible adhesive-free copper-clad laminate, which includes the following steps:

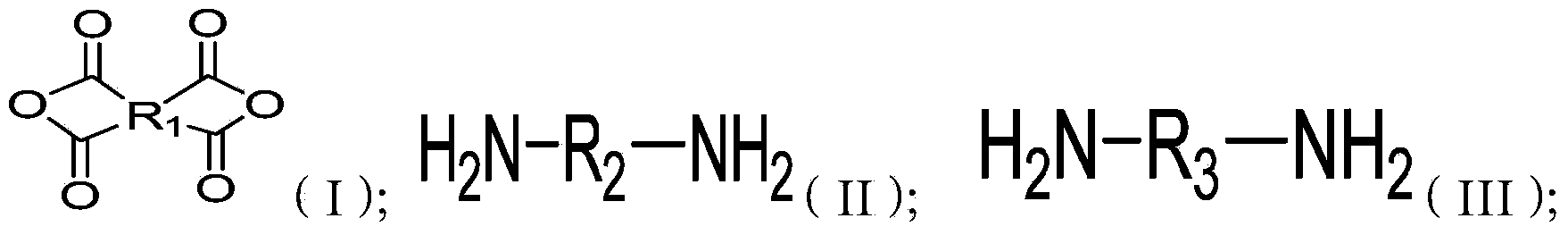

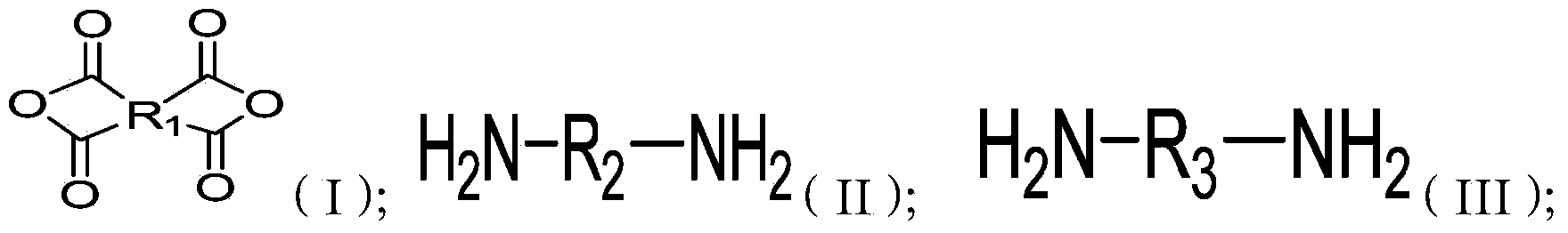

[0024] (A) The aromatic dianhydride with the structure of formula (I), the nitrogen-containing aromatic heterocyclic diamine with the structure of formula (II) and the aromatic diamine with the structure of formula (III) are polymerized in an organic solvent to obtain polyamide acid solution;

[0025]

[0026] Among them, R 1 for

[0027] R 2 for

[0028] R 3 for

[0029] (B) Coating the polyamic acid solution on a copper foil, removing the organic solvent and performing thermal imidization to obtain a flexible adhesive-free copper clad laminate.

[0030] In the present invention, aromatic dianhydrides and diamines with specific structures are selected, and polyimide resins are obtained through polymerization and imidization. The present invention selects aromatic dianhydrides with the structu...

Embodiment 1

[0038] 2,5-bis(4-aminophenyl)pyridine (1.568g, 0.006mol) and 4,4'-diaminodiphenyl ether (0.801g, 0.004mol) were added to N-methylpyrrolidone (20g) , stirred at room temperature to dissolve the solid. Add 4,4′-biphenyldianhydride (2.942 g, 0.010 mol) and stir at room temperature for 24 hours to form a polyamic acid solution.

[0039] After the polyamic acid solution was salivated and coated on the surface of the copper foil, it was dried in a vacuum oven at 110° C. for 240 minutes. Then, it was slowly heated to 300° C. in a nitrogen-protected oven and kept for 60 minutes. That is, a flexible non-adhesive copper clad laminate is obtained.

Embodiment 2

[0041]2,5-bis(4-aminophenyl)pyrimidine (1.574g, 0.006mol) and 4,4'-diaminodiphenyl ether (0.801g, 0.004mol) were added to N-methylpyrrolidone (20g) , stirred at room temperature to dissolve the solid. Add 4,4′-biphenyldianhydride (2.942 g, 0.010 mol) and stir at room temperature for 24 hours to form a polyamic acid solution.

[0042] After the polyamic acid solution was salivated and coated on the surface of the copper foil, it was dried in a vacuum oven at 110° C. for 240 minutes. Then, it was slowly heated to 300° C. in a nitrogen-protected oven and kept for 60 minutes. That is, a flexible non-adhesive copper clad laminate is obtained.

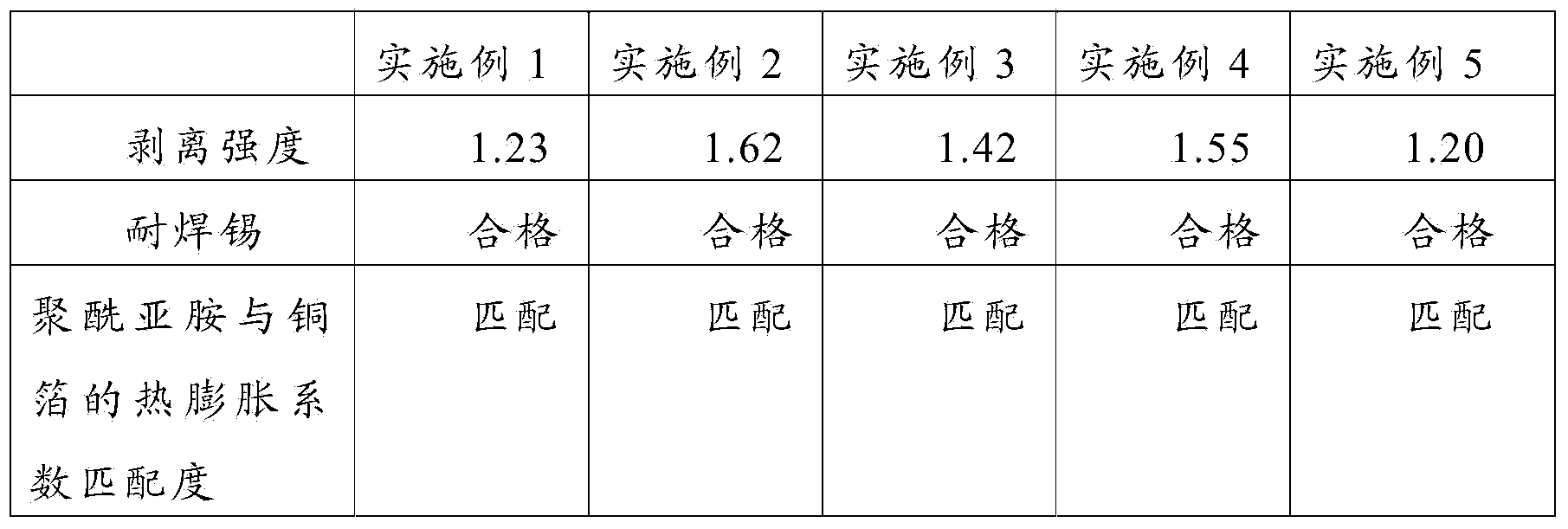

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com