Welding device for automobile rear-axle housing flange ring

A technology of welding device and rear axle of automobile, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as affecting the efficiency of production, product quality, etc., and achieve the effects of simple structure, improved positioning accuracy, and convenient welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

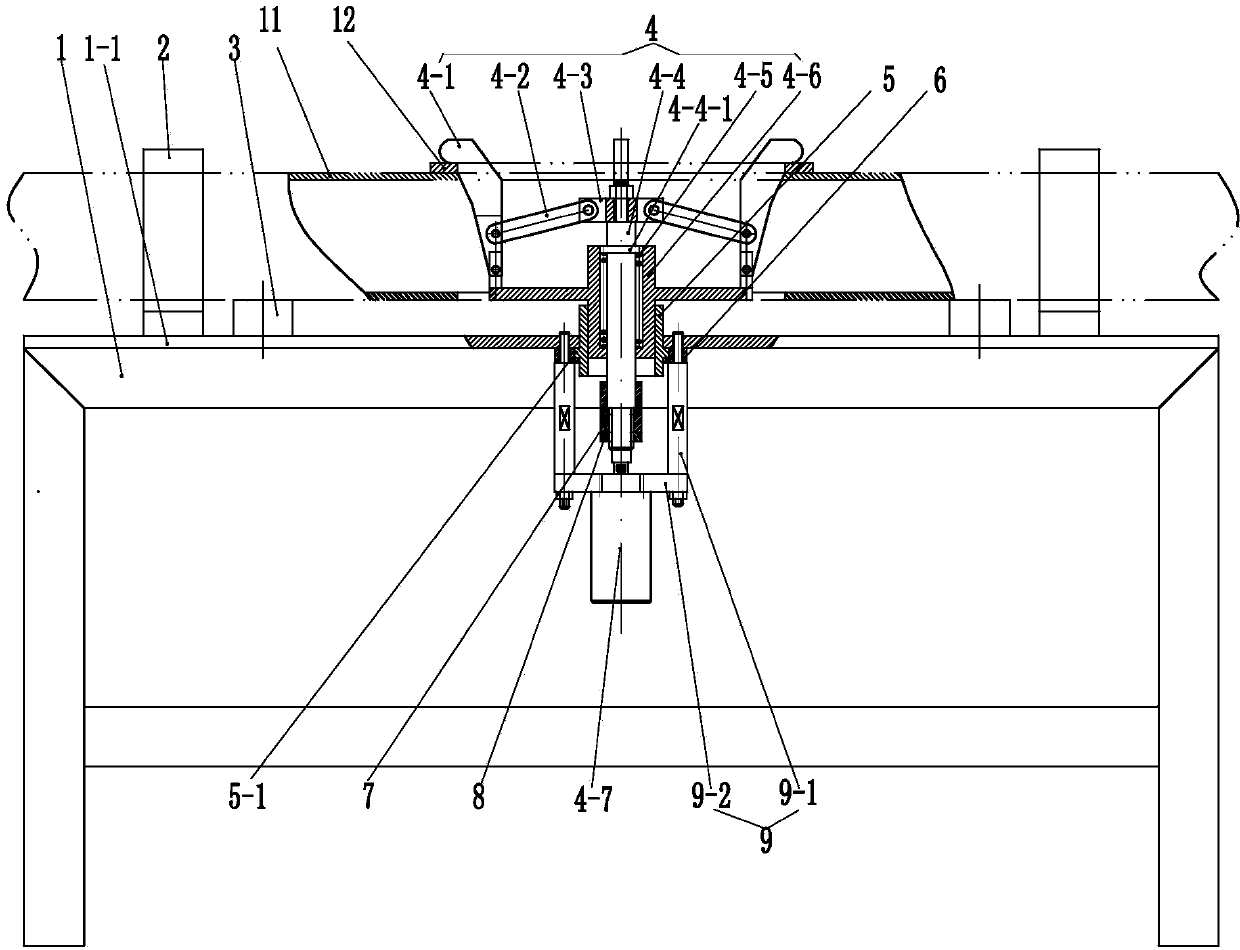

[0027] See Figure 3 to Figure 16 , this embodiment has a workbench 1 and a flange ring positioning mechanism 4 . A mounting hole is provided on the platen 1-1 of the workbench 1, and a supporting sleeve 5 is provided in the mounting hole.

[0028] The bottom of the support sleeve 5 is provided with an annular boss 5-1, and the annular boss 5-1 of the support sleeve 5 is against the bottom surface of the platen, and the outer circumference of the annular boss 5-1 is provided with a clamping sleeve 6 for clamping. The cavity of the sleeve 6 is a stepped cavity, and the stepped cavity of the clamping sleeve 6 cooperates with the annular boss 5-1 of the supporting sleeve 5, and the supporting sleeve 5 is supported by the clamping sleeve 6.

[0029] The bottom of platen 1-1 is provided with hanger 9, and hanger 9 is made up of base plate 9-2 and four stud bolts 9-1, and the upper end of stud bolt 9-1 passes through the bolt hole on the clamping sleeve 6 and The platens of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com