Method and device for manufacturing wallboards through sludge

A sludge and wallboard technology, applied in the method and its device, in the field of using sludge to make wallboards, can solve the problems of increasing the limitation of sludge utilization and increasing the controversy of sludge treatment, etc., and achieves the advantages of easy promotion, low investment and high production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: A method for making wallboard by utilizing sludge, the partition wallboard comprises the following components in parts by weight: 23 parts of dodecylbenzene sulfonic acid, 3 parts of sodium hydroxide, ethoxylated 8 parts of sodium alkyl sulfate, 5 parts of inorganic fibers, 20 parts of magnesia, 200 parts of cement, 500 parts of sludge, 900 parts of water, wherein the sludge is municipal sludge, and the moisture content of the sludge is 65% .

[0032] The production steps are as follows:

[0033] (1) Weigh the components according to the weight ratio;

[0034] (2) injecting dodecylbenzene sulfonic acid, sodium hydroxide, sodium ethoxylated alkyl sulfate and water into a foaming machine for foaming to form a foam mixture; wherein in this step, the amount of water used is the total amount of water. 1 / 3 of the weight part.

[0035] (3) Put the inorganic fibers, magnesia, cement, sludge and the remaining water into the mixing equipment to fully stir to f...

Embodiment 2

[0039] Example 2: A method for making wallboards by using sludge, the partition wallboard includes the following components in parts by weight: 26 parts of dodecylbenzene sulfonic acid, 4 parts of sodium hydroxide, ethoxylated 9 parts of sodium alkyl sulfate, 10 parts of inorganic fibers, 25 parts of magnesia, 250 parts of cement, 550 parts of sludge, and 850 parts of water, wherein the moisture content of the sludge is 70%, and the preparation method is the same as that in Example 1.

[0040]

Embodiment 3

[0041] Embodiment 3: a method for making wallboard by utilizing sludge, the partition wallboard comprises the following components in parts by weight: 30 parts of dodecylbenzene sulfonic acid, 4 parts of sodium hydroxide, ethoxylated 10 parts of sodium alkyl sulfate, 15 parts of inorganic fibers, 30 parts of magnesia, 300 parts of cement, 600 parts of sludge, and 700 parts of water, wherein the moisture content of the sludge is 75%, and the preparation method is the same as that of Example 1.

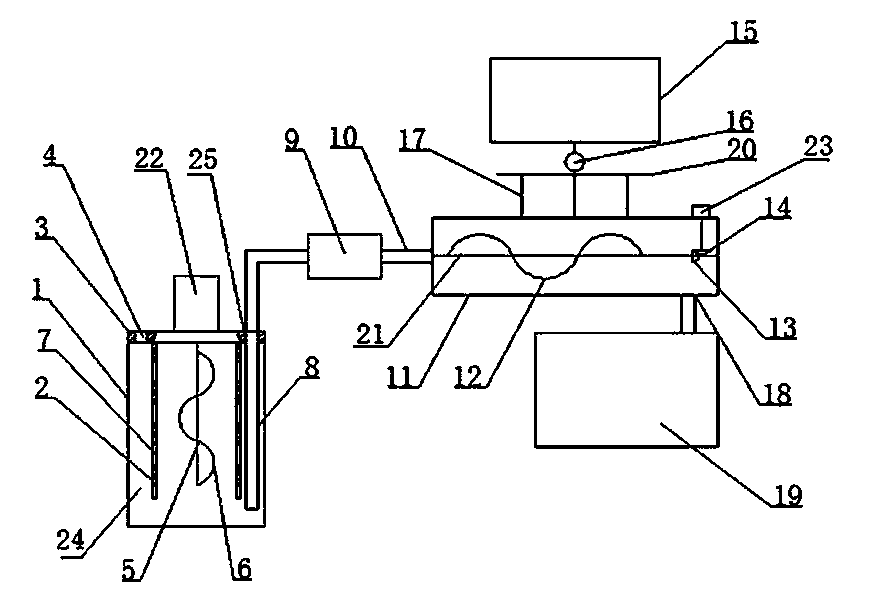

[0042] like figure 1 As shown, a device for making wall panels from sludge includes a stirring device, a sludge pump 9, a foaming machine 15, a mixing device and a plate making machine 19. The stirring device and the sludge pump 9 feed The port is communicated through the feeding pipe 8, and the discharge port of the sludge pump 9 is communicated with the mixing equipment through the discharging pipe 10; the discharge port of the foaming machine 15 is connected with a jet pump 16, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com