Composite phenolic resin sandwich panel

A phenolic resin and sandwich panel technology, which is applied in the field of plastic sheets, can solve the problems of flammability, low compressive strength, and poor aging resistance of the sheet, so as to increase the roughness, increase the bonding area, and improve the bonding the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

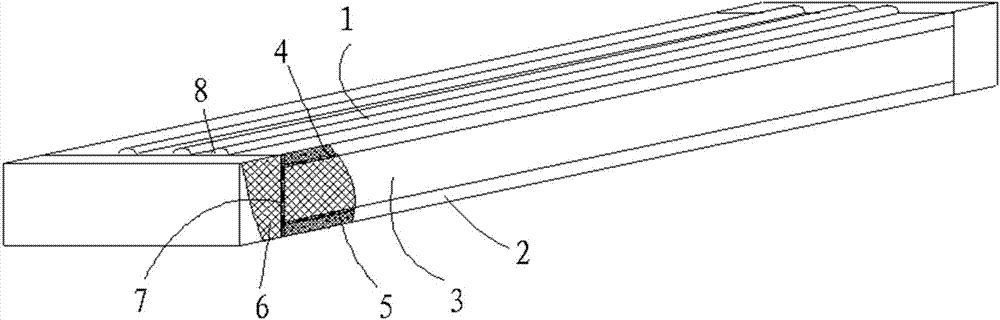

[0015] Such as figure 1 As shown, a phenolic resin composite sandwich panel includes a first plate body 1 and a second plate body 2. A sandwich layer 3 is provided between the first plate body 1 and the second plate body 2. The board body 1 and the second board body 2 are made of phenolic resin plates. The inner surfaces of the first board body 1 and the second board body 2 are subjected to sandblasting or rough grinding with a grinding wheel, and the inner surface is roughened to form a rough inner surface. The upper surface layer 4, the lower surface layer 5, and the two sides of the sandwich layer are respectively bonded to the rough inner surface layers of the first plate body and the second plate body through epoxy resin glue. Of course, the inner surfaces of the first plate and the second plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com