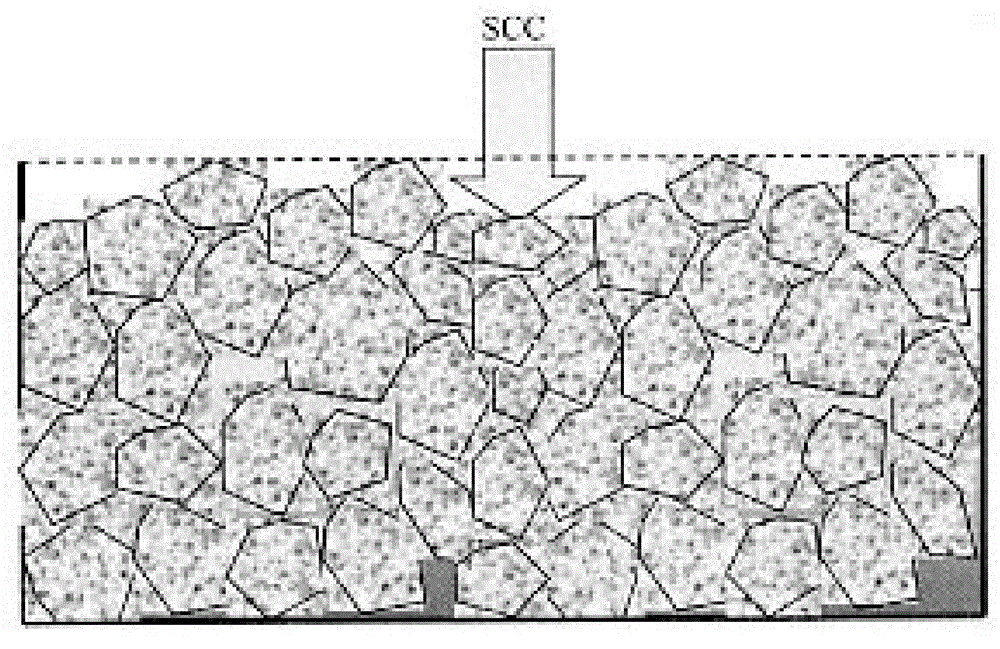

a rockfill concrete

A rockfill concrete and crushed stone technology, which is applied in the field of construction engineering, can solve problems such as endangering the safety of dams, cracking of concrete, low late strength and late strength, etc., and achieves the effects of increasing service life, reducing temperature and hot seam, and reducing cement consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0027] A rockfill concrete composed of water, cement, crushed stone, sand, mineral powder, fly ash, water reducing agent, and stones. The weight parts of each raw material are shown in Table 1 (the stones are the volume fractions). The composition of the comparative example includes water, cement, crushed stone, sand, fly ash, water reducing agent and stones. The weight parts of each raw material are shown in Table 1 (the stones are the volume fractions).

[0028] In Examples 1-9 and Comparative Examples, the cement is ordinary Portland cement with a strength grade of 42.5; the crushed stone is 5-15mm continuous graded crushed stone; the mineral powder is S95 grade mineral powder; The sand is medium sand with a fineness modulus of 2.4-2.6; the water-reducing agent is a polycarboxylic acid series high-efficiency water-reducing agent; the particle size of the stone is 150-200mm; and the fly ash is Class I.

[0029] Table 1

[0030] Numbering

Water

Gravel

Sand

Mineral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com