Nanosized silica thermal insulation material and preparation method based on normal-temperature drying wet process thereof

A nano-silicon oxide, thermal insulation technology, applied in the field of thermal insulation materials and thermal insulation, can solve the problems of long production cycle, high cost, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

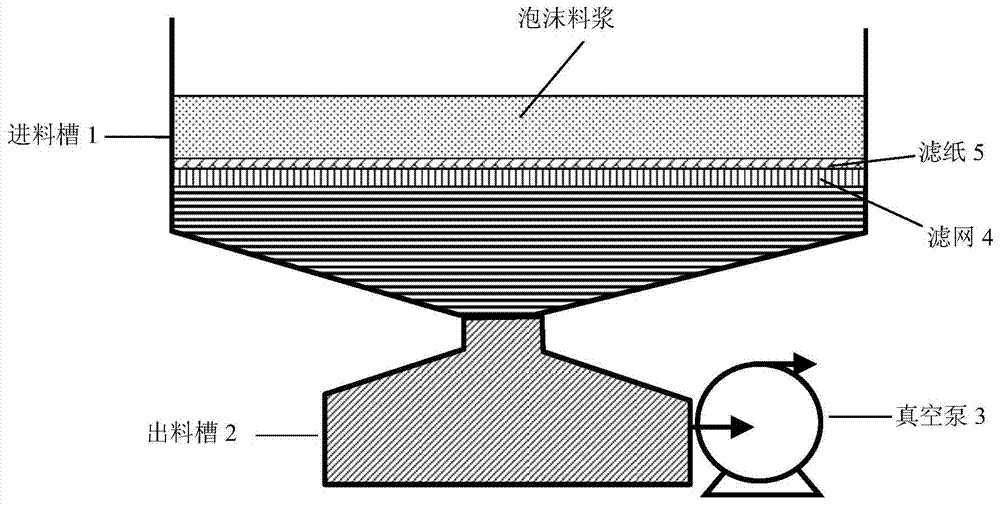

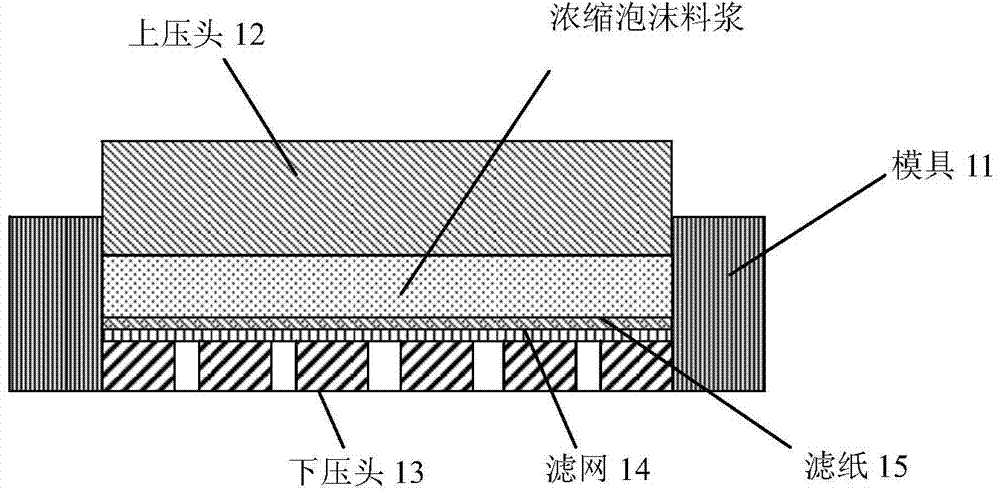

Method used

Image

Examples

Embodiment 1-7

[0029] Embodiment 1-7, prepare nano silicon oxide thermal insulation material with normal temperature dry wet process

[0030] The raw material formula of embodiment 1-7 nano silicon oxide thermal insulation material is as shown in table 1:

[0031] Table 1 Embodiment 1-7 Raw material formula of nano-silica thermal insulation material (addition unit in the table: parts by weight)

[0032]

[0033]In the examples, the nano silicon oxide powder is prepared by the gas phase method (preferred) or the liquid phase method and has undergone hydrophobic treatment. For the method of preparing nano silicon oxide by the gas phase method, see, Shao Q G, Gu G B, Zhang L J.The application research of micro emulsion in the preparation of nanometer materials.New Chemical Materials.2001,29(7):9-13), the method of preparing nano silicon oxide by liquid phase method, see, Hu Bing, Jiang Binbo, Chen Jizhong. Monodisperse Preparation and application of non-reactive SiO2. Chemical progress. 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com