Method for reducing ammonia content and blasting property of medium-pressure emptying gas

A medium-pressure, gas technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of urea derivatives, etc., can solve problems such as increasing explosiveness, reduce explosiveness, simple and reliable operation, and improve safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

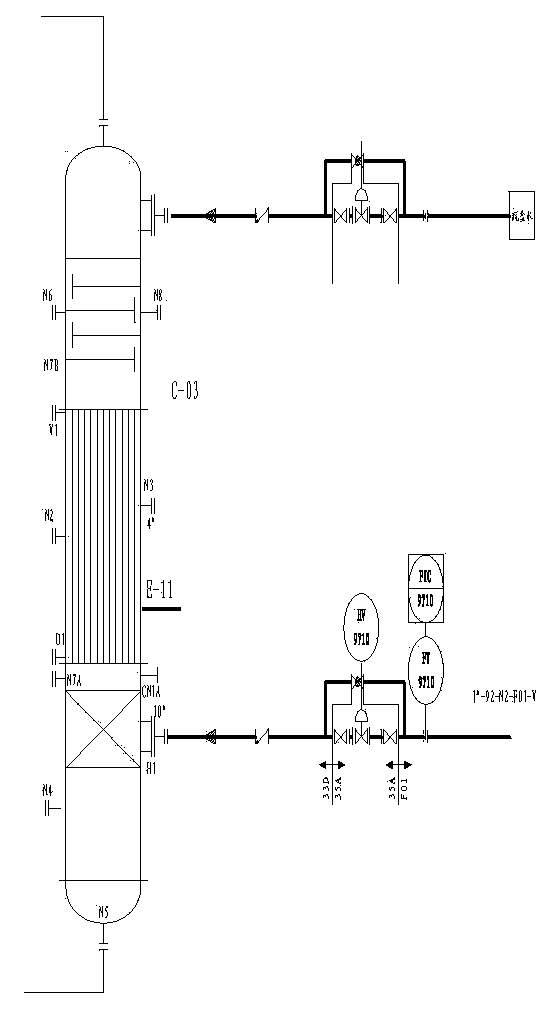

Image

Examples

example 1

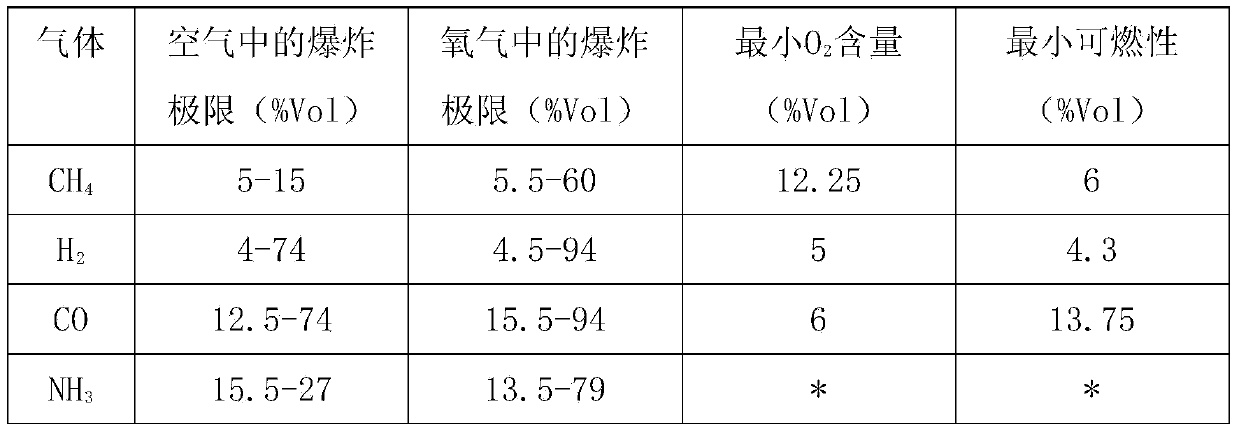

[0022] A method for reducing ammonia content in medium-pressure venting gas and its explosiveness in urea production, said method comprising adding a layer of packing to absorb (0.71m 2 Stainless steel Pall ring packing 00Cr19Ni10, specification: 38×38×0.6mm), reduce the ammonia content in the medium-pressure vent gas, and continuously add 2.2MPa nitrogen to the medium-pressure ammonia absorber equipment to prevent the medium-pressure vent gas from entering the explosion limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com