Synthetic process of poly MA-AA-Mac (Maleic Anhydride-Acrylic Acid-Methyl Acrylate) anti-scale agent through control of reaction time

A technology of reaction time and synthesis process, applied in the direction of scale removal and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost, limited use, and large amount of addition, and achieve reduction The effect of preparation cost, improvement of anti-scaling performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A kind of polyMA-AA-Mac antifouling agent synthetic technique that the present invention relates to controlled reaction time, comprises steps:

[0024] (a) at first, prepare maleic anhydride solution, acrylic acid solution and methyl acrylate respectively;

[0025] (b) Then, in reaction vessel, add maleic anhydride solution, acrylic acid solution and methyl acrylate;

[0026] (c) adding initiator in reaction vessel;

[0027] (d) Then start the stirring and heating device, keep the stirring reaction at a constant temperature for 3h-6h, then stop, and cool naturally to obtain the target product.

[0028] The reaction vessel is a four-necked bottle with stirring device, dropping funnel, thermometer and condensing device.

[0029] The three dropping funnels were filled with acrylic acid solution, methyl acrylate and ammonium persulfate solution respectively.

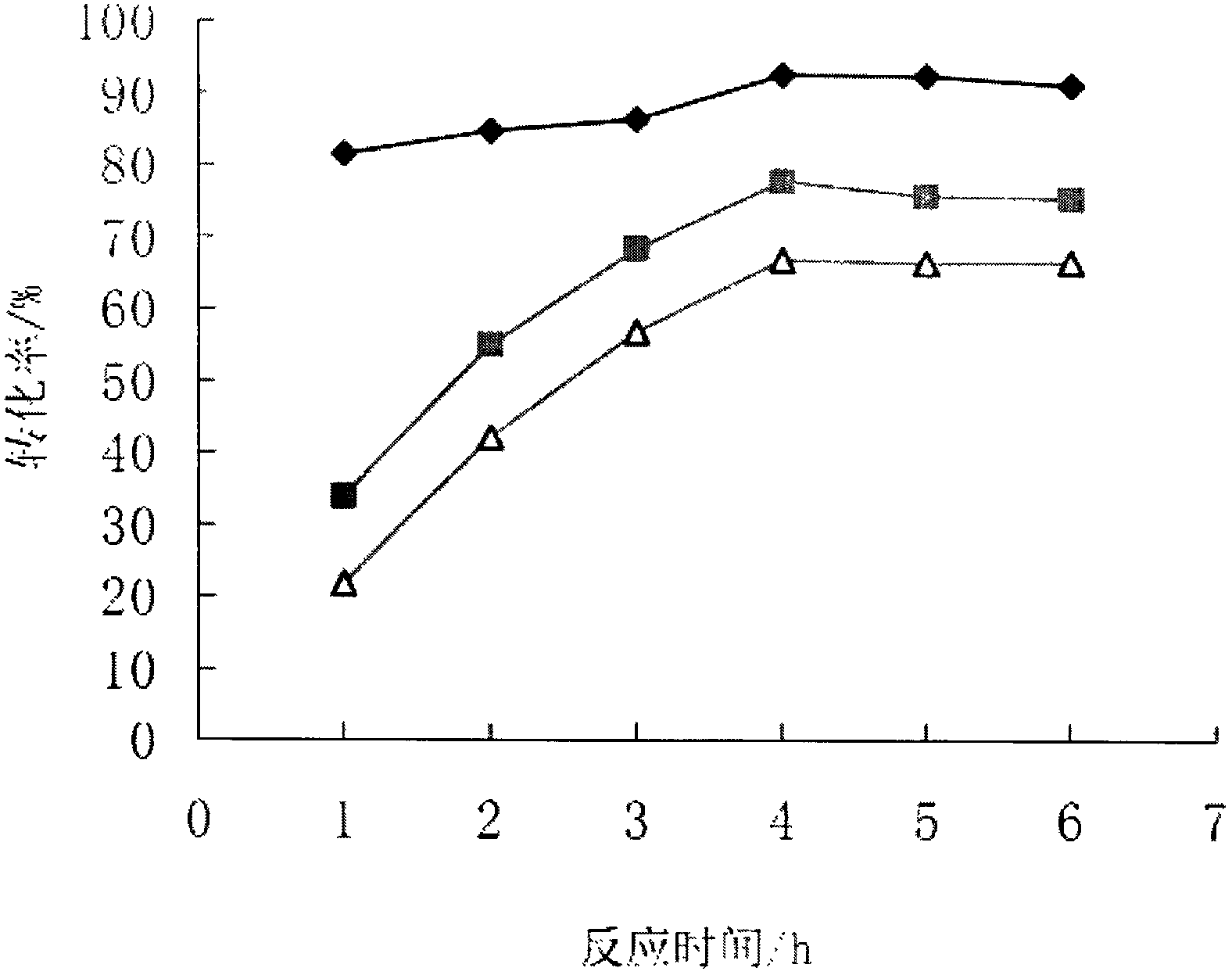

[0030] In order to obtain the best initiator consumption, the present invention has done the comparative experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com