Far-infrared carbon-based composite electrothermal ink and its preparation method and application

An electrothermal ink and far-infrared technology, applied in the field of ink, can solve the problems of insufficient far-infrared radiation rate, weak influence on the human body, low effect of physical therapy and health care, etc., and achieve the effect of simple preparation process, low cost and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The tourmaline powder is added with an appropriate amount of water, stirred, ball milled and superfinely ground, and finally spray-dried to form a composite oxide powder with a particle size distribution of 0.1-2.0 μm.

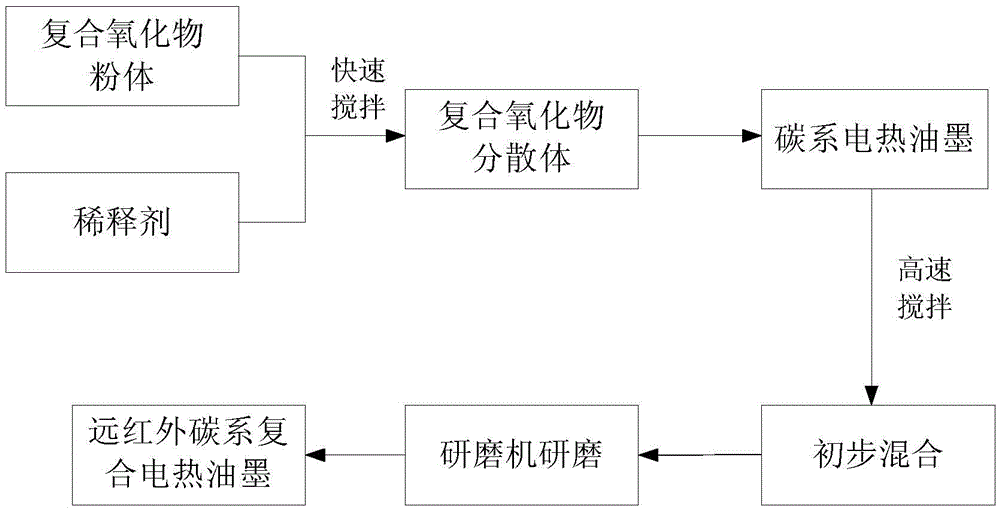

[0030] figure 1 It is a schematic flow chart of the preparation method of the far-infrared carbon-based composite electrothermal ink of the present invention, as figure 1 As shown, take 2 g of the above composite oxide powder, add 4 g of isophorone, and stir rapidly until the powder is uniformly dispersed to form a composite oxide dispersion.

[0031] Add the uniformly dispersed composite oxide dispersion into 92g of carbon-based electrothermal ink, and stir at a high speed at a speed of 2500-3000 rpm, mix thoroughly for 20-30 minutes, and then grind in a grinder for 3-5 Repeat until the system is uniform and stable, and the far-infrared carbon-based composite electrothermal ink of the present invention is obtained. In this embodiment, the parameters ...

Embodiment 2

[0034] Mix tourmaline powder and Sibin pumice powder at a ratio of 2:1, add an appropriate amount of water, carry out stirring, ball milling and ultrafine grinding, and finally spray dry to make a composite oxide powder with a particle size of 0.1-2.0 μm body.

[0035] Take 15 g of the above composite oxide powder, add 40 g of isophorone, and stir rapidly until the powder is uniformly dispersed to form a composite oxide dispersion.

[0036] Add the uniformly dispersed composite oxide dispersion into 945g carbon-based electrothermal ink, and stir at a high speed at a speed of 2500-3000 rpm, mix thoroughly for 20-30 minutes, and then place it in a grinder for 3-5 minutes. Repeat until the system is uniform and stable, and the far-infrared carbon-based composite electrothermal ink of the present invention is obtained. In this embodiment, the parameters of the carbon-based electrothermal ink used as raw materials are: viscosity 300P, solid content 78%, resistivity 40Ω / sq.

[003...

Embodiment 3

[0039] Mix seagull stone powder, Sibin pumice powder and tourmaline powder in a ratio of 2:2:1, add appropriate amount of water, stir, ball mill and ultrafine grind, and finally spray dry to make a particle size of 0.1~ 2.0μm composite oxide powder.

[0040] Take 50 g of the above composite oxide powder, add 50 g of isophorone, and stir rapidly until the powder is uniformly dispersed to form a composite oxide dispersion.

[0041] Add the uniformly dispersed composite oxide dispersion into 900g carbon-based electrothermal ink, stir at a high speed at a speed of 2500-3000 rpm, mix thoroughly for 20-30 minutes, and then place it in a grinder for 3-5 minutes. Repeat until the system is uniform and stable, and the far-infrared carbon-based composite electrothermal ink of the present invention is obtained. In this embodiment, the parameters of the carbon-based electrothermal ink used as raw materials are: viscosity 300P, solid content 78%, resistivity 40Ω / sp.

[0042] After testin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com