Method for producing metallized iron powder based on carbon circulation oxygen increasing direct reduction of powdery iron ore

A technology for metallizing iron powder and iron ore, applied in the field of metallurgy, can solve the problems of difficulty in industrialized utilization, low grade of iron fine powder, difficult development and utilization, etc. Reaction effect, the effect of saving raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

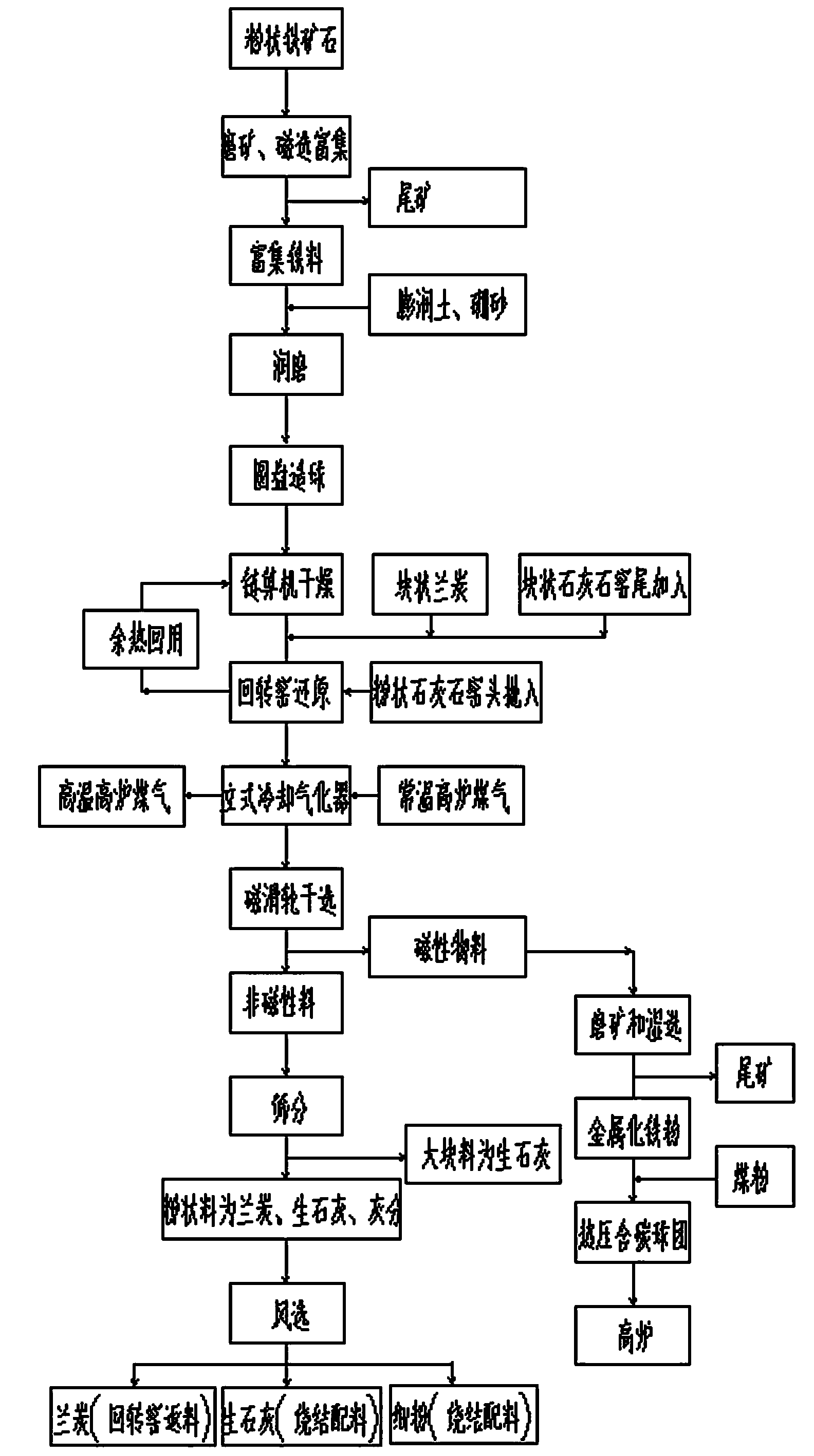

Image

Examples

Embodiment 1

[0067] A. Selection of raw materials

[0068] The particle size of iron ore is less than 2mm, the mass of fixed carbon in blue carbon is >70%, and the particle size of blue carbon is 3-8mm; limestone is divided into powdered limestone and massive limestone. The particle size is 8 ~ 16mm;

[0069] B, grinding and magnetic separation enrichment

[0070] The iron ore is ground, and the grinding particle size is 200 mesh, and the magnetic separation enrichment makes the iron grade of the iron ore more than 40%;

[0071] C, making balls

[0072] Mix the enriched iron ore, bentonite and borax in a weight ratio of 100:2.5:0.6;

[0073] D. Grinding of mixed materials

[0074] The mixed material is poured into the grinding machine, and the grinding time is 8-10 minutes;

[0075] E. Grinding material to make balls

[0076] The grinding material is transported into the ball machine, water is sprayed on the grinding material to make it wet, and the ball machine works to roll the gri...

Embodiment 2

[0092] A. Selection of raw materials

[0093] The particle size of iron ore is less than 2mm, the mass of fixed carbon in blue carbon is >70%, and the particle size of blue carbon is 3-8mm; limestone is divided into powdered limestone and massive limestone. The particle size is 8 ~ 16mm;

[0094] B, grinding and magnetic separation enrichment

[0095] The iron ore is ground, and the grinding particle size is 200 mesh, and the magnetic separation enrichment makes the iron grade of the iron ore more than 40%;

[0096] C, making balls

[0097] The enriched iron ore, bentonite and borax are mixed and batched in a weight ratio of 100: 3.0: 0.9;

[0098] D. Grinding of mixed materials

[0099] The mixed material is poured into the grinding machine, and the grinding time is 8-10 minutes;

[0100] E. Grinding material to make balls

[0101] The grinding material is transported into the ball machine, water is sprayed on the grinding material to make it wet, and the ball machine w...

Embodiment 3

[0117] A. Selection of raw materials

[0118] The particle size of iron ore is less than 2mm, the mass of fixed carbon in blue carbon is >70%, and the particle size of blue carbon is 3-8mm; limestone is divided into powdered limestone and massive limestone. The particle size is 8 ~ 16mm;

[0119] B, grinding and magnetic separation enrichment

[0120] The iron ore is ground, and the grinding particle size is 200 mesh, and the magnetic separation enrichment makes the iron grade of the iron ore more than 40%;

[0121] C, making balls

[0122] Mix the enriched iron ore, bentonite and borax in a weight ratio of 100:2.8:0.8;

[0123] D. Grinding of mixed materials

[0124] The mixed material is poured into the grinding machine, and the grinding time is 8-10 minutes;

[0125] E. Grinding material to make balls

[0126] The grinding material is transported into the ball machine, water is sprayed on the grinding material to make it wet, and the ball machine works to roll the gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com