Coating device and coating method for winding type sputtering three-layer dielectric film

A layer of dielectric film and coating device technology, which is applied in the field of vacuum coating equipment, can solve the problems of limited installation quantity, large equipment, and large production area, so as to achieve consistent sputtering target distance, accurate sputtering target distance, and prolong the film forming time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

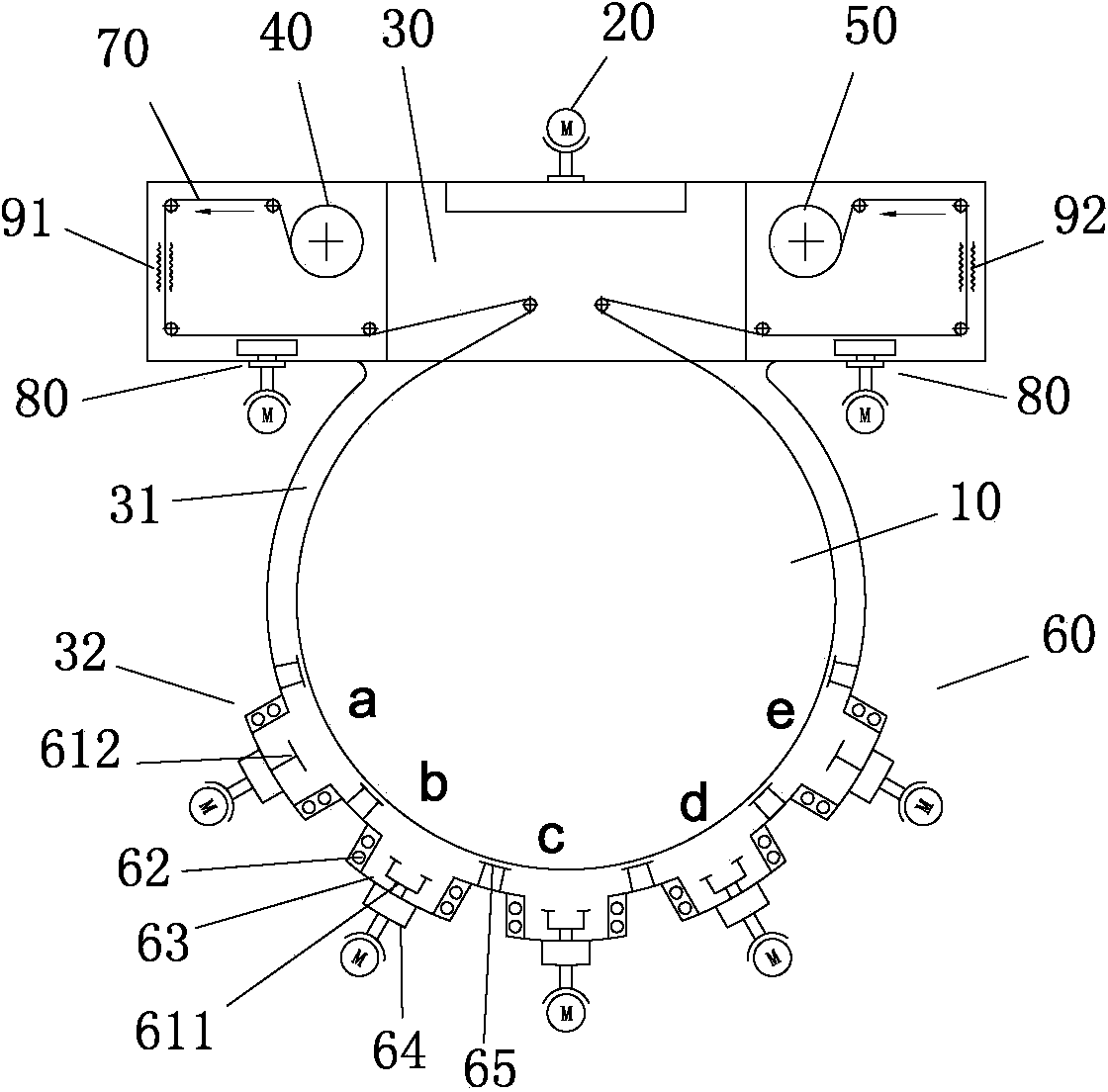

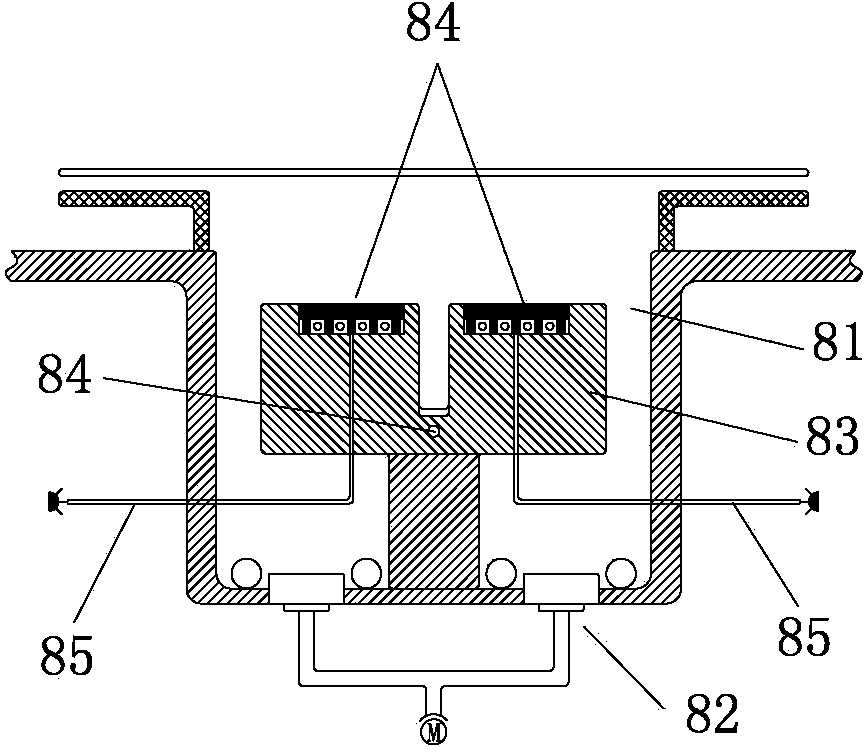

[0020] Such as Figure 1-2 As shown, a coating device for rolling sputtering three-layer dielectric film includes: a chill roll 10, a main motor 20 driving the chill roll 10, a vacuum chamber 30 covering the chill roll 10, and an unwinding mechanism 40. The winding mechanism 50 and five cathode cells 60, wherein the unwinding mechanism 40, the winding mechanism 50 and the five cathode cells 60 are all built in the vacuum chamber 30, and the unwinding mechanism 40 bypasses the cold roll through the raw film 70 The circumferential surface of 10 is transmitted to the winding mechanism 40 to realize the synchronous linkage of the three. The part of the vacuum chamber 30 covering the cold roll 10 is a cylindrical cavity 31, and five cathode cells 60 are arranged at intervals in the cylindrical cavity. On the inner wall of the body 31 and protruding outwards to form a cavity convex hull 32, the cathode small chamber 60 includes a cathode target body, a cooling water pipe 62, an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com