In-situ morphology and optical performance monitoring evaporation source and vacuum deposition equipment

A technology of optical performance and evaporation source, applied in vacuum evaporation plating, ion implantation plating, metal material coating process, etc., can solve the problems of material performance degradation, failure, and electrons cannot reach the surface of the sample, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

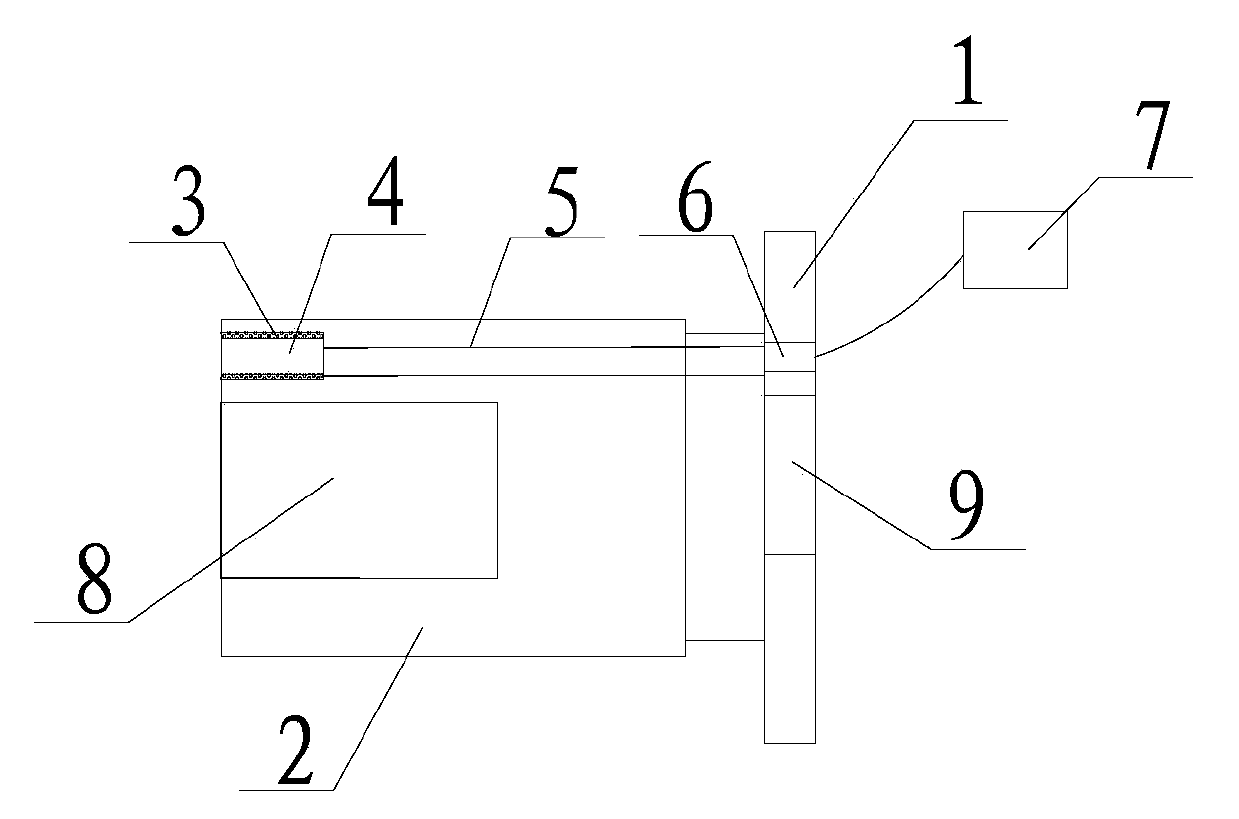

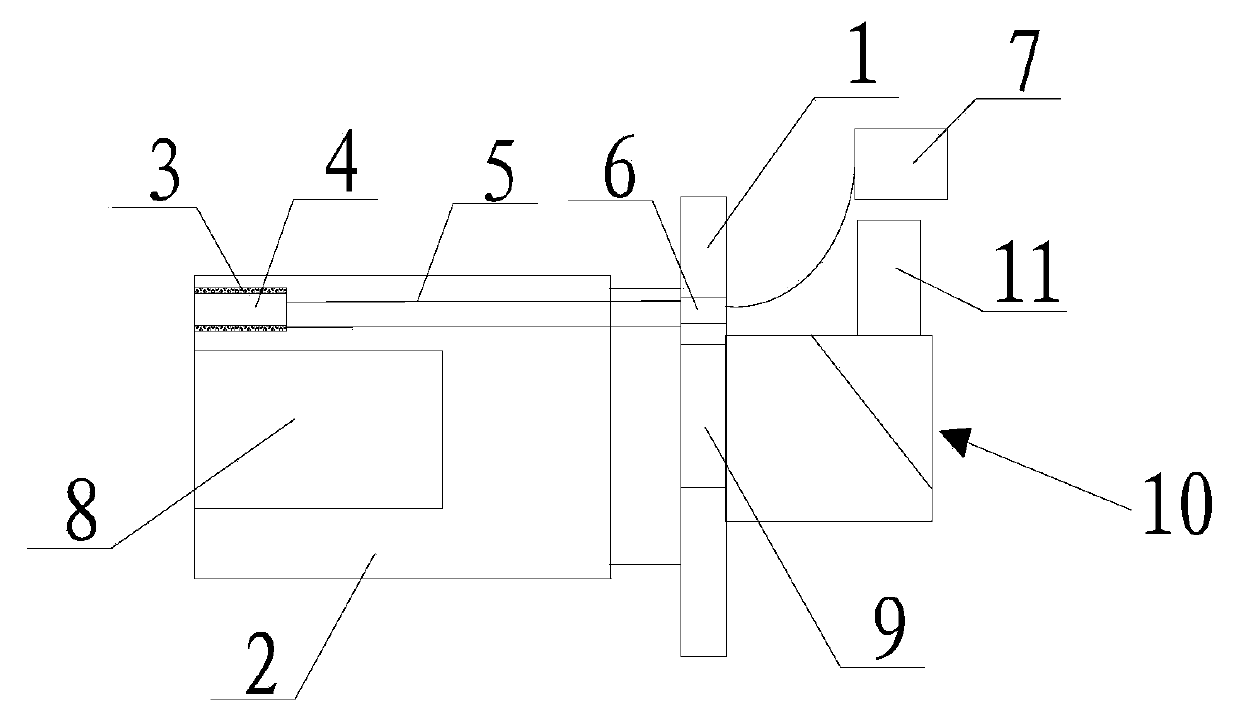

[0027] Such as image 3 The shown in-situ topography and optical performance monitoring evaporation source also includes a connected optical component 10 and an imaging component 11 in addition to the above-mentioned components. The optical assembly 10 and the heat shield assembly 2 are located on different sides of the vacuum flange 1, and are close to the observation window 9, and are used for optically processing the real-time monitoring displayed by the microscope 8 so as to be displayed on the imaging assembly 11, so that the operator can comfortably monitoring angle. The optical component 10 can be made of glass, quartz, sapphire, photonic crystal and other materials.

[0028]

Embodiment 2

[0030] Such as Figure 4 The shown in-situ morphology and optical performance monitoring evaporation source are consistent with the basic structure of the evaporation source in Example 1, the difference is that the imaging component 11 is not included, but the spectrometer 12 is connected with the optical component 10 and the detector 13 respectively. connection, enabling a more accurate record of the optical properties of the deposited evaporated material. The spectrometer 12 can be a spectrometer intensity detector or a charge-coupled device (CCD), etc., and is used to record in real time the changes of various optical information such as photofluorescence and Raman information during the film growth process. It generally includes a light source, a collimating mirror, a spectroscopic Mirror or grating, signal collection detector.

Embodiment 3

[0032] Such as Figure 5 The shown in-situ morphology and optical performance monitoring evaporation source are consistent with the basic structure of the evaporation source in Example 1, except that the optical component 10 is also connected to the spectrometer 12, and the spectrometer 12 is also connected to the detector 13, And it also includes a computer system 14, which is respectively connected with the imaging component and the detector for data collection and data processing. Simultaneous configuration of imaging component 11, spectrometer 12 and detector 13 can realize the associated evolution of morphology and optical properties, and can perform micro-area analysis on the surface of the film; after connecting with computer system 14, the measured data can be digitized, and Control, data acquisition, data processing, etc. for all operations through the same computer.

[0033] Install any in-situ morphology and optical performance monitoring evaporation source in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com