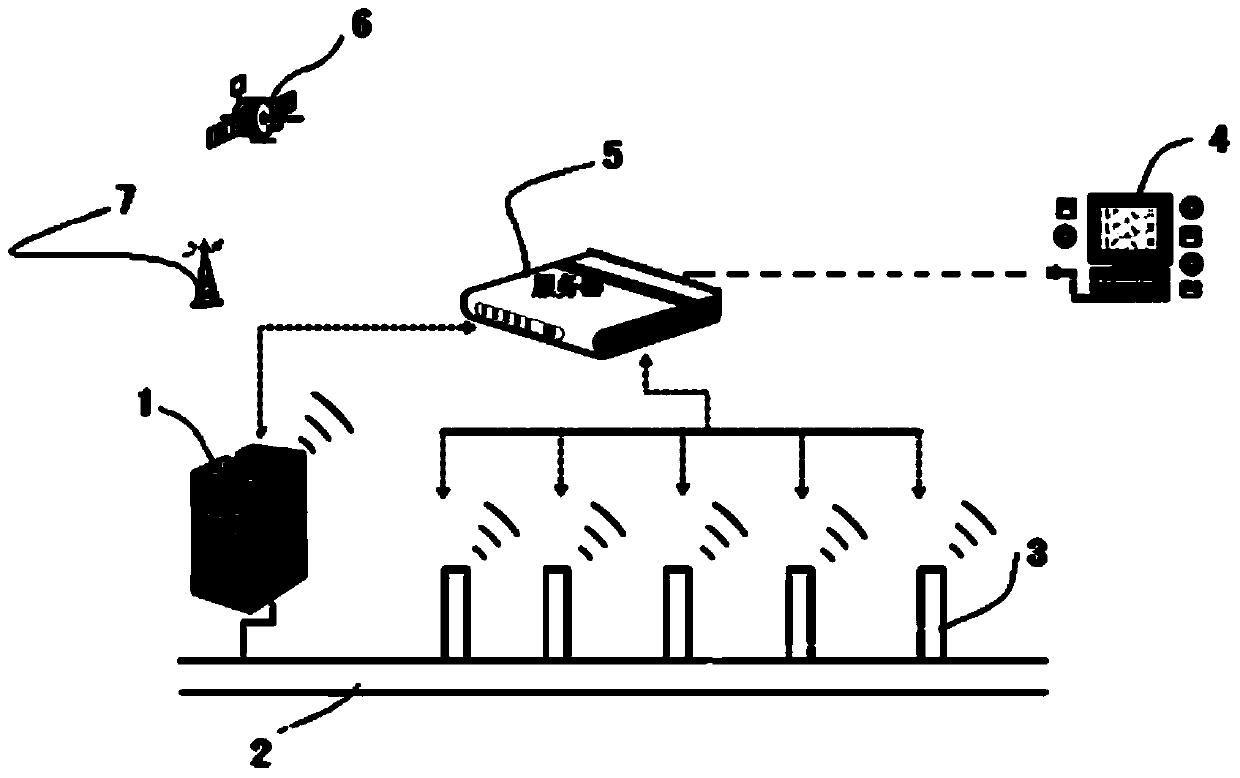

Intelligent remote monitoring method for protecting cathode of underground pipeline

A technology for cathodic protection and underground pipelines, applied in the field of cathodic protection of underground pipelines, intelligent remote monitoring, and monitoring, which can solve problems such as hidden safety hazards, failure to monitor and adjust protection systems, and failure of pipelines and storage tanks to know the real status of cathodic protection in time. , to achieve the effect of rapid and accurate search, accurate data, and expansion of monitoring items and data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

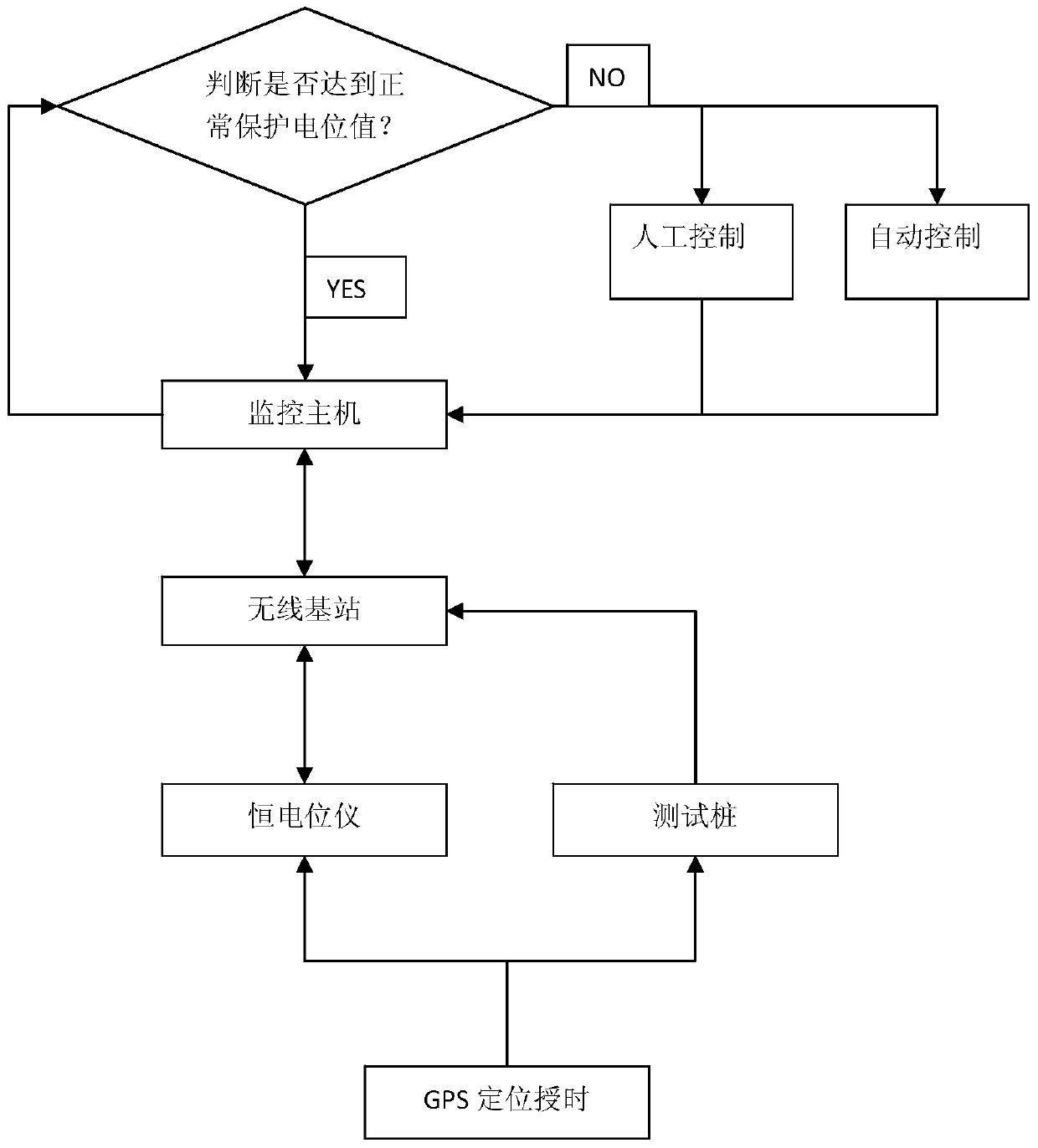

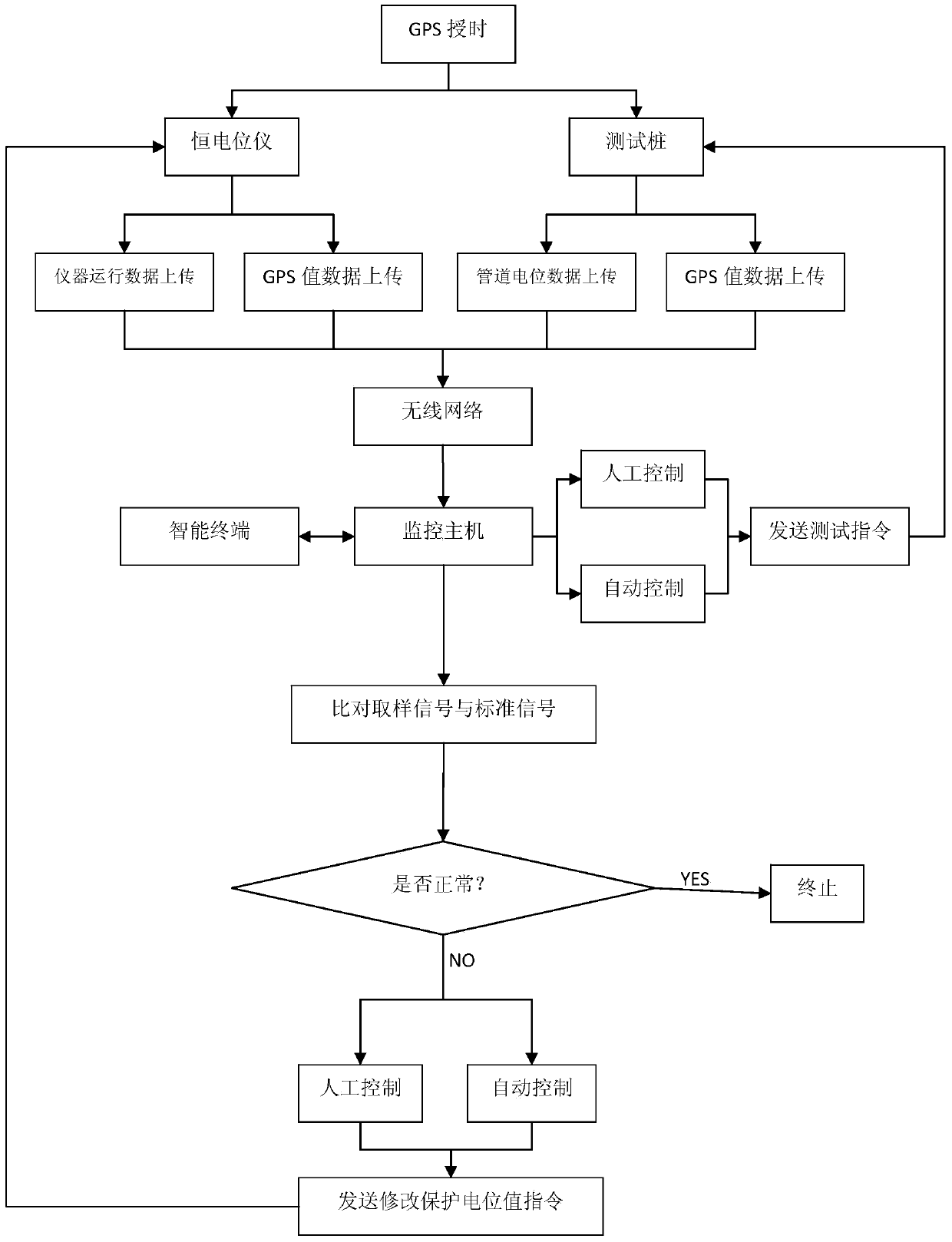

[0063] The interval time between the data upload of the potentiostat and the test pile is set by the command sent by the monitoring host. The data upload interval of the potentiostat is short, usually 5 minutes, and the higher data upload frequency can obtain as real-time data as possible; the data upload interval of the test pile is longer, usually 12 hours, for daily routine test data collection. When data is uploaded, the potentiostat and the test pile independently perform GPS time service and synchronize time through the GPS module assembled to ensure the time accuracy of data upload.

[0064] The potentiostat uploads its operating data and GPS data to the monitoring host through the wireless network according to the set time frequency, and the test pile uploads its potential data and GPS data to the monitoring host through the wireless network according to the set time frequency, and the monitoring host receives After the sampling signal uploaded by the potentiostat or ...

Embodiment 2

[0067] Carry out daily data sampling work according to Example 1. If the sampling signal is not within the normal threshold range of the standard signal, the monitoring host judges that the sampling signal is abnormal, and the monitoring personnel manually calculate the modification value according to the sampling signal, and issue the modification command manually. To the potentiostat, the potentiostat modifies its working potential value after receiving the modification command from the monitoring host, so that the cathodic protection current of the pipeline under its jurisdiction works normally.

[0068] At the same time, monitoring personnel can also manually issue test instructions, modify the time interval for uploading test pile data, increase the data upload time and frequency of test piles, or control the test piles in real time to perform power-off tests and upload data, so as to facilitate troubleshooting.

[0069] In addition to the fully automated operation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com