Vent valve type exhaust brake system

A technology of exhaust brake and air release valve, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of unreasonable structure of the braking system, engine damage, limited braking force, etc., and achieve easy control, Uniform braking force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

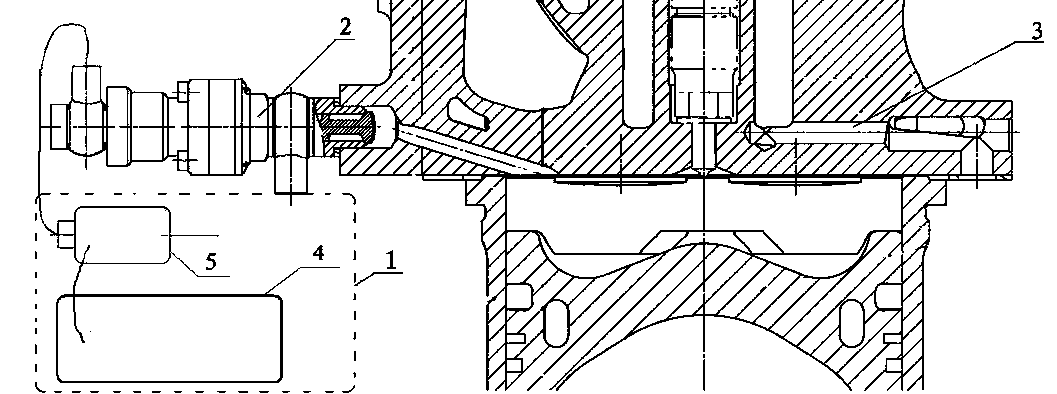

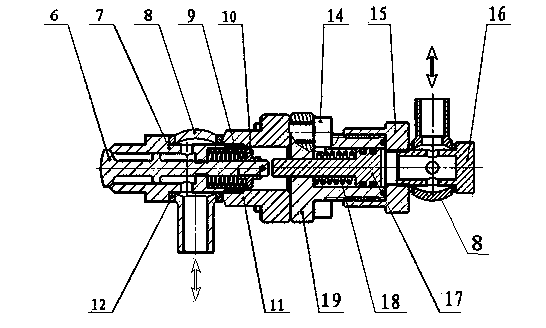

[0017] Such as figure 1 and figure 2 As shown, a bleed valve type exhaust brake system includes a control assembly 1, a brake assembly 2 and a cylinder head 3, the control assembly 1 includes an ECU electronic controller 4 and a hydraulically driven valve, and the brake assembly 2 includes a throttle valve 6. Air release valve sleeve 7, hollow ball joint 8, air release valve return spring 9, adjustment cap 10, brake valve end cover 11, gasket 12, screw 14, cylinder head 15, hollow bolt 16, piston 17, The return spring 18 and the cylinder liner 19, wherein the throttle valve 6 is set in the air release valve sleeve 7, the air release valve return spring 9 and the adjustment cap 10 are set on the throttle valve 6, and the air release valve return spring 9 and the adjustment cap 10 are installed In the brake valve end cover 11, the hollow ball joint 8 is set between the brake valve end cover 11 and the air release valve sleeve 7, and is sealed by the gasket 12, the screw 14 is ...

Embodiment 2

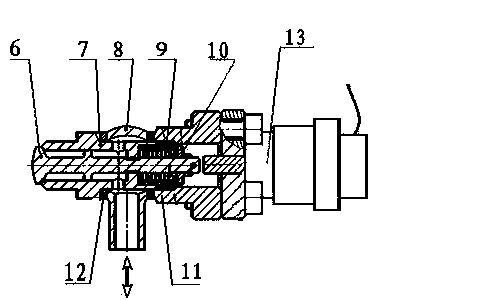

[0022] Such as figure 1 and image 3 As shown, a bleed valve type exhaust brake system includes a control assembly 1, a brake assembly 2 and a cylinder head 3, the control assembly 1 includes an ECU electronic controller 4 and an electromagnetic drive valve, and the brake assembly 2 includes a throttle valve 6. Air release valve sleeve 7, hollow ball joint 8, air release valve reset spring 9, adjustment cap 10, brake valve end cover 11, gasket 12 and electromagnetic push rod, among which the throttle valve 6 is set on the air release valve sleeve 7, the air release valve return spring 9 and the adjustment cap 10 are set on the throttle valve 6, the air release valve return spring 9 and the adjustment cap 10 are installed in the brake valve end cover 11, and the hollow ball joint 8 is set on the brake valve Between the valve end cover 11 and the deflation valve sleeve 7, it is sealed by a gasket 12; the ECU electronic controller 4 is connected with the drive valve 5, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com