Copper-clad aluminum alloy compound wire

A composite wire, copper-aluminum alloy technology, used in metal/alloy conductors, rods/rods/wires/strip conductors, electrical components, etc., can solve the problems of consuming copper resources and increasing the cost of manufacturers, and achieves no production Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described in further detail below through the description of the best embodiment with reference to the accompanying drawings.

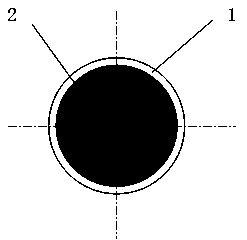

[0014] as attached figure 1 As shown, the copper-clad aluminum alloy composite wire is composed of an outer pure copper layer 1 and an inner aluminum alloy core wire 2 .

[0015] The cleaned and air-dried pure copper strip and the aluminum alloy core wire enter the composite unit synchronously. The pure copper strip passes through six sets of vertical and horizontal alternately arranged molds, and gradually forms a round tube to wrap around the aluminum alloy core wire. Then, the on-line argon Arc welding uses the protection of inert gas argon to weld the tubular pure copper strip longitudinally to form a fully enclosed round tube and wrap it around the aluminum alloy core wire to form a copper-clad aluminum alloy composite wire billet. Among them, there is a gap between the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com