IGBT power device for low power application and method of manufacturing the same

A technology of power device and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, semiconductor device, electrical components, etc., to achieve the effect of improving turn-off time, turn-on and turn-off time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

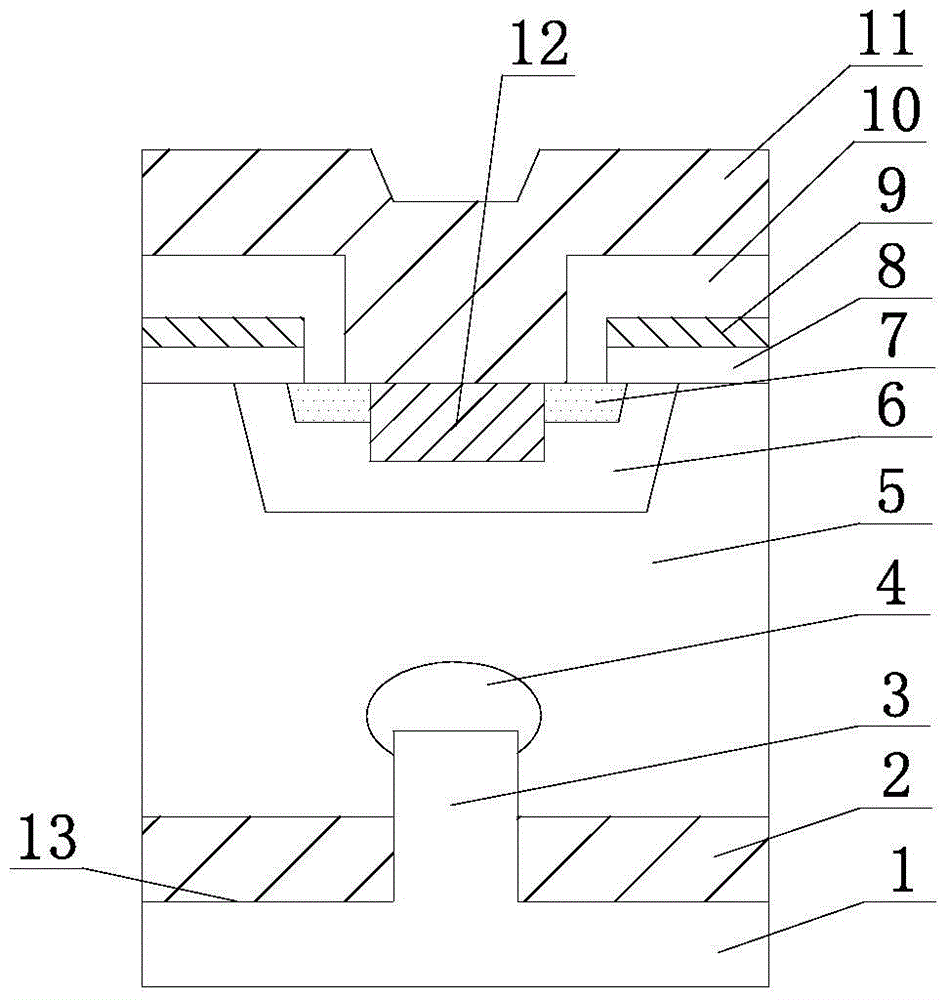

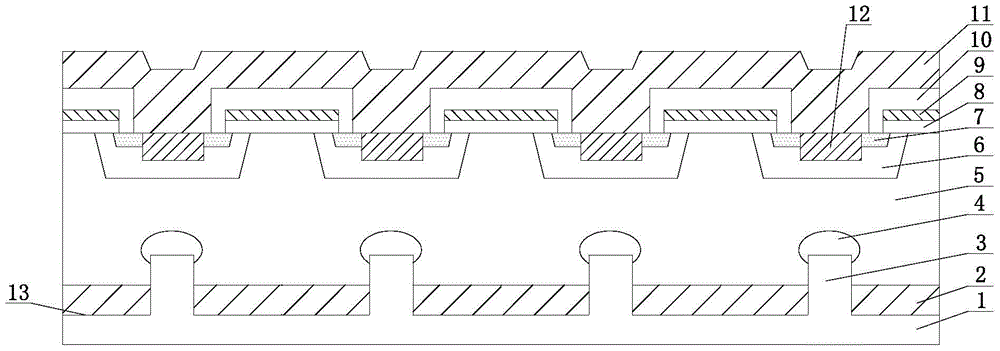

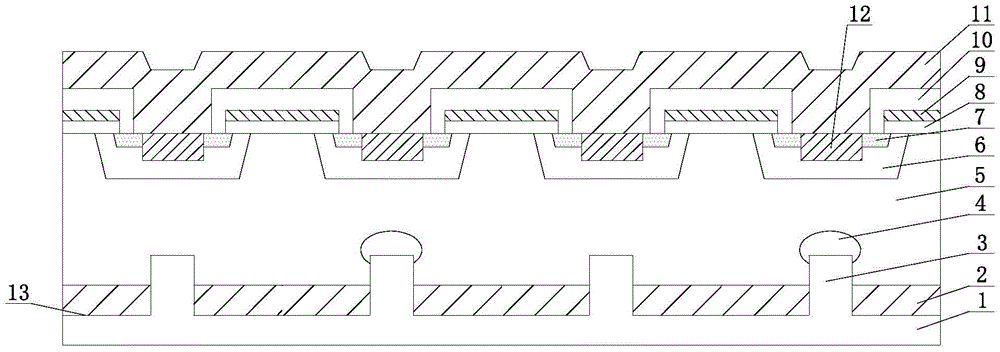

[0021] In order to facilitate those skilled in the art to further understand the present invention, clearly understand the technical solutions of the present invention, and fully and fully disclose the relevant technical content of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Of course The described specific embodiments only list a part of the embodiments of the present invention, rather than all the embodiments, to help understand the present invention and its core ideas.

[0022] The basic idea of the present invention is to optimize the design of the backside structure of the IGBT, to increase the metal-filled trench without affecting the voltage resistance of the device itself, to heavily dope the P-type, and to only use the trench surface (especially the trench The bottom of the groove) is injected into the N-type region, the N-type region can also be arranged in a rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com