Clamp diode, layout structure thereof and manufacturing method thereof

A clamping diode and high-resistance technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unfavorable integrated circuit miniaturization, increased integrated chip area, and high integrated circuit manufacturing cost, and achieve reverse Improved leakage characteristics and reduced device reverse leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

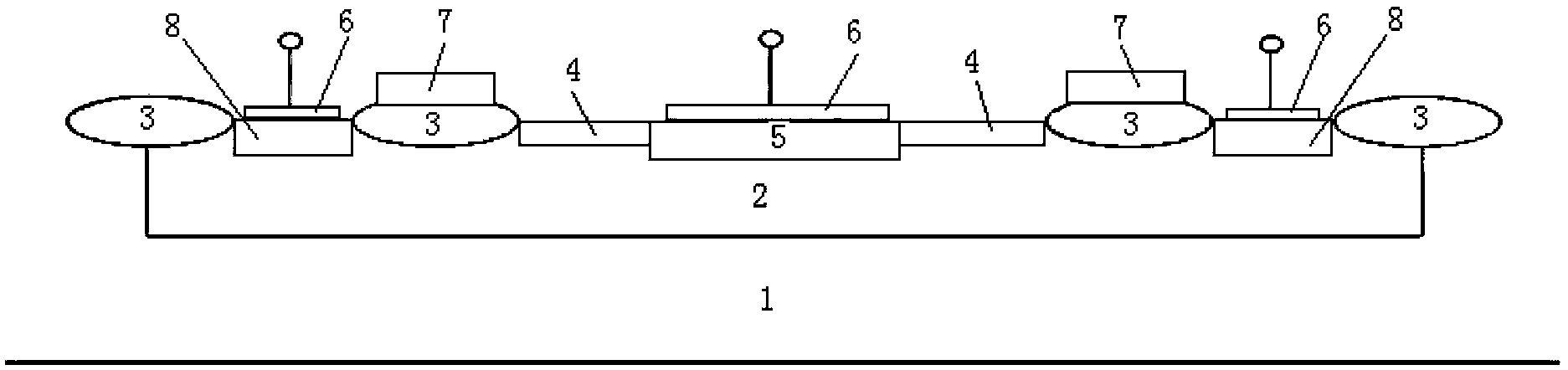

[0038] Such as figure 1 As shown, the clamping diode of the present invention includes:

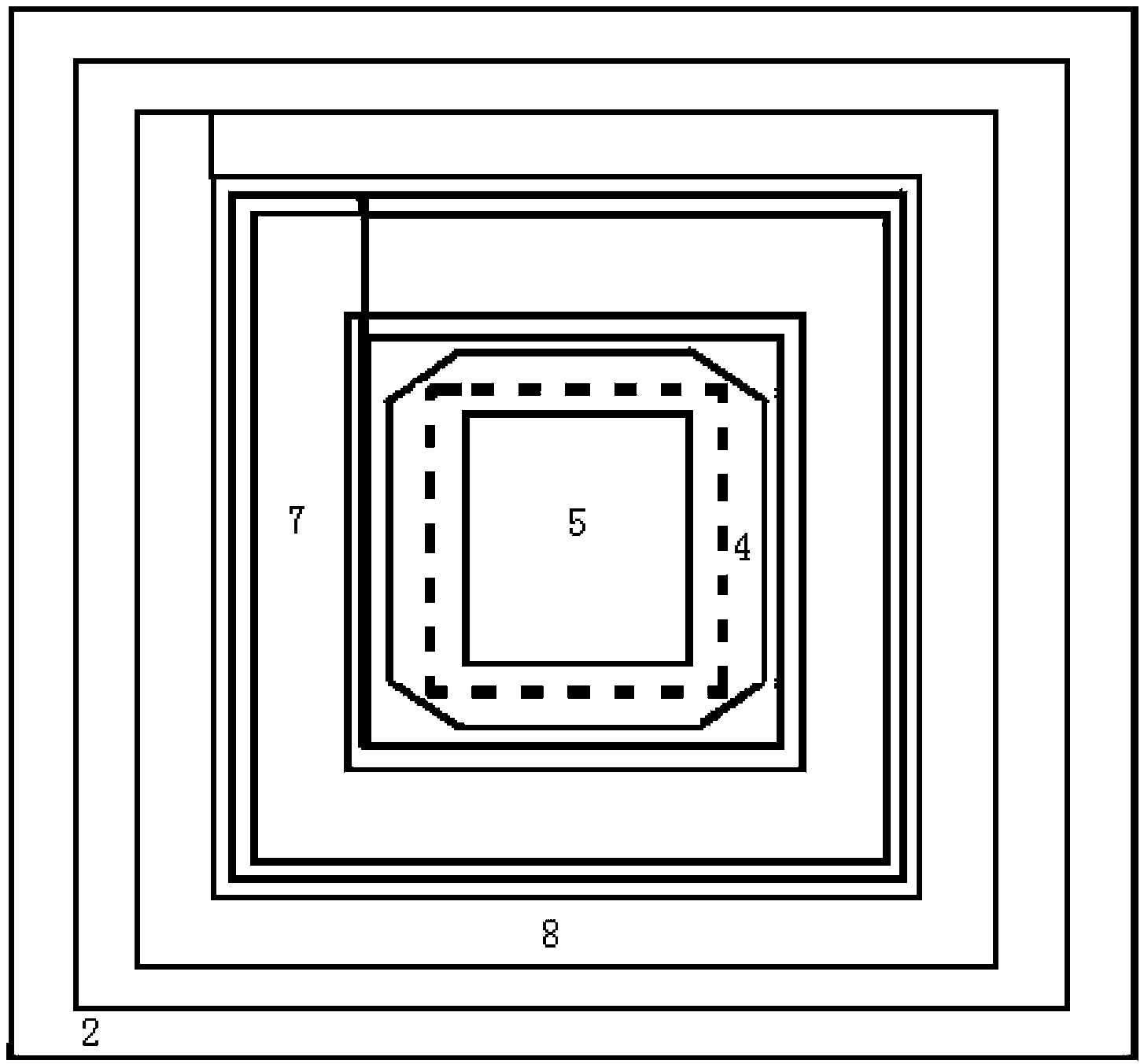

[0039] The N-type well region 2 on the P-type substrate 1, the P-type high-resistance region 4 on the top of the N-type well region 2, and the P-type low-resistance region 5 between the P-type high-resistance regions 4, and the P-type high-resistance region 4. There is an insulating region 3 on the outside, an N+ doped region 8 is located between the two insulating regions 3 on the same side of the P-type high-resistance region 4, and a polysilicon layer 7 is provided on the insulating region 3 adjacent to the P-type high-resistance region 4. There is a metal silicide 6 on the type low resistance region 5 and the N+ doped region 8;

[0040] The P-type high-resistance region 4 and the P-type low-resistance region 5 lead out through the metal silicide 6 to form the anode of the clamping diode;

[0041] The N+ doped region 8 leads out through the metal silicide 6 to form the cathode of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com