Preparation method for carbon nano tube/ oxidized grapheme/ nanometer Fe3O4 sandwich hybrid wave absorbing thin films

A technology for the preparation of carbon nanotubes and thin films, which is applied in the field of material science, can solve the problems of poor magnetic properties of carbon nanotubes and affect the dispersion performance of carbon nanotubes, and achieve the effects of large specific surface area, excellent electromagnetic wave absorption performance, and improved magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

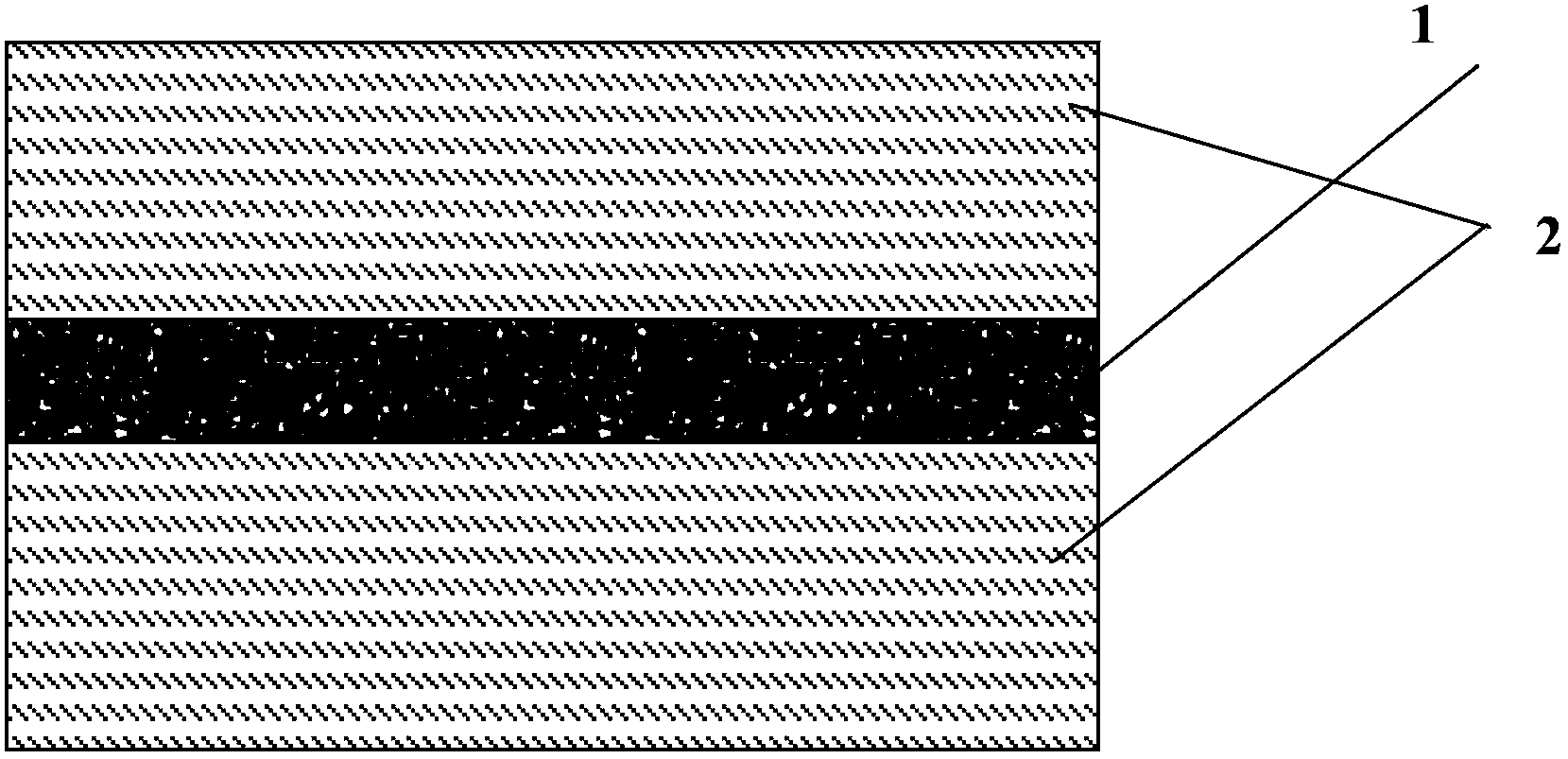

[0017] refer to figure 1 , 1 in the figure is Fe 3 o 4 layer; 2 is a carbon nanotube / graphene oxide hybrid layer.

[0018] Carbon Nanotube / Graphene Oxide / Nano-Fe 3 o 4 The preparation method of the sandwich hybrid wave-absorbing film is realized through the following steps:

[0019] (1) Graphite oxide was prepared by the Hummers method, adding graphite oxide to plasma water, and ultrasonically dispersed for 60 minutes to form a brown graphene oxide solution with uniform color. After high-speed centrifugation at 8000rpm for 20 minutes, the supernatant was taken, and the concentration of graphite oxide was 0.5wt%;

[0020] (2) Preparation of graphene oxide-carbon nanotube aqueous solution: add carbon nanotubes to the graphene oxide aqueous solution, stir magnetically for 80 minutes, disperse ultrasonically for 60 minutes, and take the supernatant after centrifugation. Wherein the carbon nanotubes are multi-walled carbon nanotubes, graphene oxide: carbon nanotube weight rati...

Embodiment 2

[0025] (1) Graphite oxide was prepared by the Hummers method. Graphite oxide was added to plasma water, and ultrasonically dispersed for 20 minutes to form a coffee-colored graphene oxide solution with uniform color. After high-speed centrifugation, the supernatant was taken, and the concentration of graphite oxide was 0.01wt%;

[0026] (2) Preparation of graphene oxide-carbon nanotube aqueous solution: add carbon nanotubes to the graphene oxide aqueous solution, stir magnetically for 30 minutes, disperse ultrasonically for 20 minutes, and take the supernatant after centrifugation. Wherein the carbon nanotubes are single-walled carbon nanotubes, multi-walled carbon nanotubes or functionalized carbon nanotubes, the weight ratio of graphene oxide:carbon nanotubes is 1:1, the concentration of carbon nanotubes is 0.01wt%, and the graphene oxide The concentration is 0.01wt%;

[0027] (3) Nano Fe 3 o 4 Dispersion preparation: the water-soluble nano-Fe 3 o 4 Dissolved in the mixt...

Embodiment 3

[0031] (1) Graphite oxide was prepared by the Hummers method. Graphite oxide was added to plasma water, and ultrasonically dispersed for 180 minutes to form a brown graphene oxide solution with uniform color. After high-speed centrifugation, the supernatant was taken, and the concentration of graphite oxide was 1 wt%;

[0032](2) Preparation of graphene oxide-carbon nanotube aqueous solution: add carbon nanotubes to the graphene oxide aqueous solution, stir magnetically for 180 minutes, disperse ultrasonically for 60 minutes, and take the supernatant after centrifugation. Wherein the carbon nanotubes are single-walled carbon nanotubes, multi-walled carbon nanotubes or functionalized carbon nanotubes, the weight ratio of graphene oxide:carbon nanotubes is 10:1, the concentration of carbon nanotubes is 0.1wt%, and the graphene oxide The concentration is 1wt%;

[0033] (3) Nano Fe 3 o 4 Dispersion preparation: the water-soluble nano-Fe 3 o 4 Dissolved in the mixture of deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com