Method for manufacturing a superhydrophobic film sheet

A thin-film, super-hydrophobic technology is applied in the field of preparation of super-hydrophobic thin-film sheets to ensure automatic cleaning, shorten curing time, and save processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific features and advantages of the present invention will be further clarified through the following detailed description based on the accompanying drawings. It should be noted beforehand that when it is judged that the detailed description of known functions and structures related to the present invention may obscure the gist of the present invention, the detailed description thereof will be omitted.

[0027] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

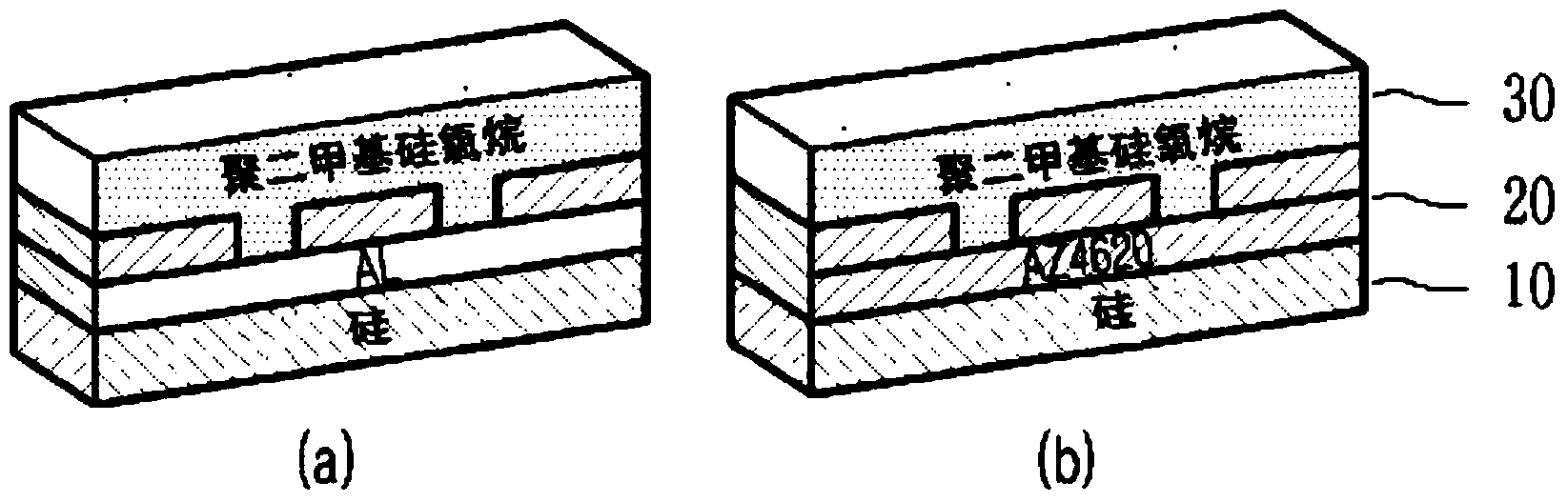

[0028] refer to Figure 1 to Figure 6 , the superhydrophobic film sheet of the present invention and its preparation method are described as follows.

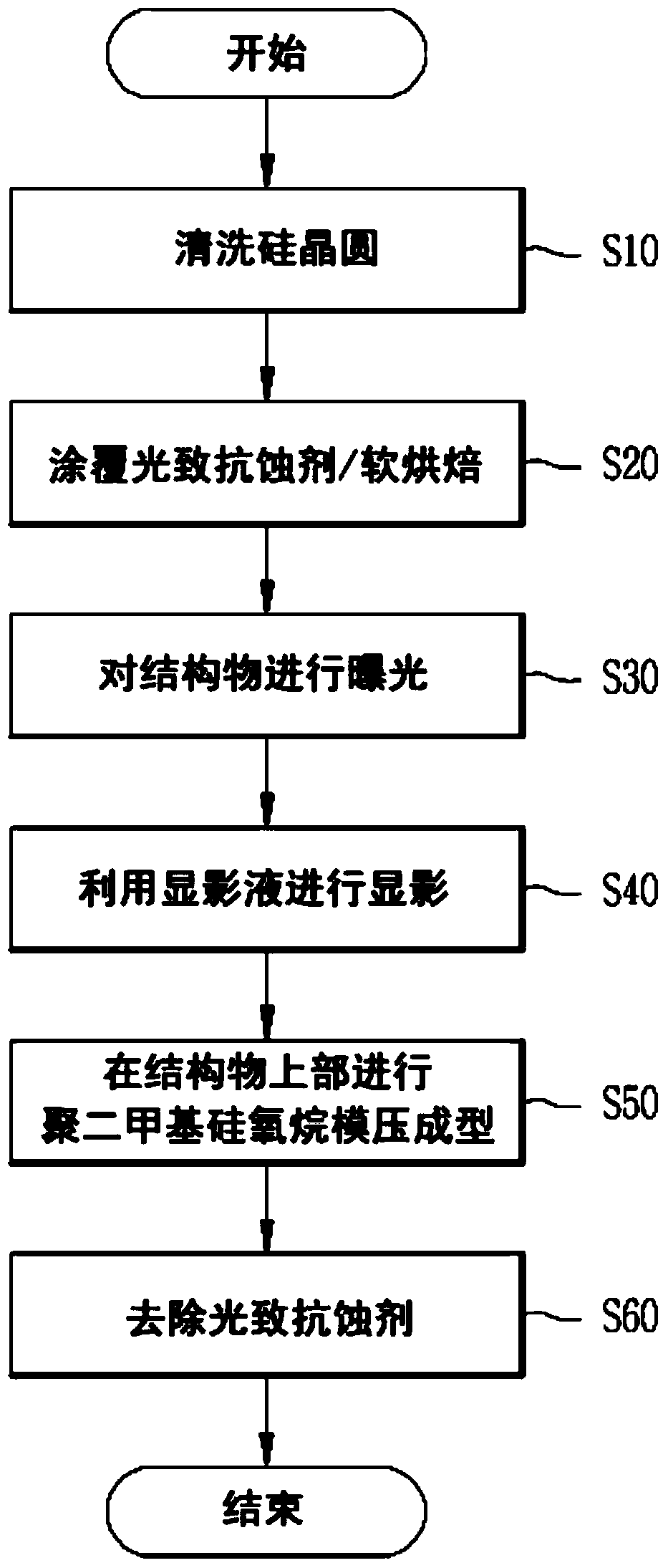

[0029] figure 1 It is a flow chart about the preparation method of the superhydrophobic film sheet of the present invention, as shown in the figure, the silicon wafer 10 is cleaned (S10).

[0030] At this time, the surface of the silicon wafer can be cleaned with Pirana, RCA1, RCA2, or the like....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com