Long-acting controlled-release antibacterial real silk woven type surgical suture and preparing method thereof

A suture and slow-release technology, applied in braids, equipment configuration for processing textile materials, liquid/gas/vapor yarn/filament processing, etc., can solve the problem of excessive accumulation of antibacterial coating materials, affecting antibacterial effect, and uniform antibacterial agent. It can achieve the effect of long-acting slow-release antibacterial effect, reducing the risk of excessive accumulation, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

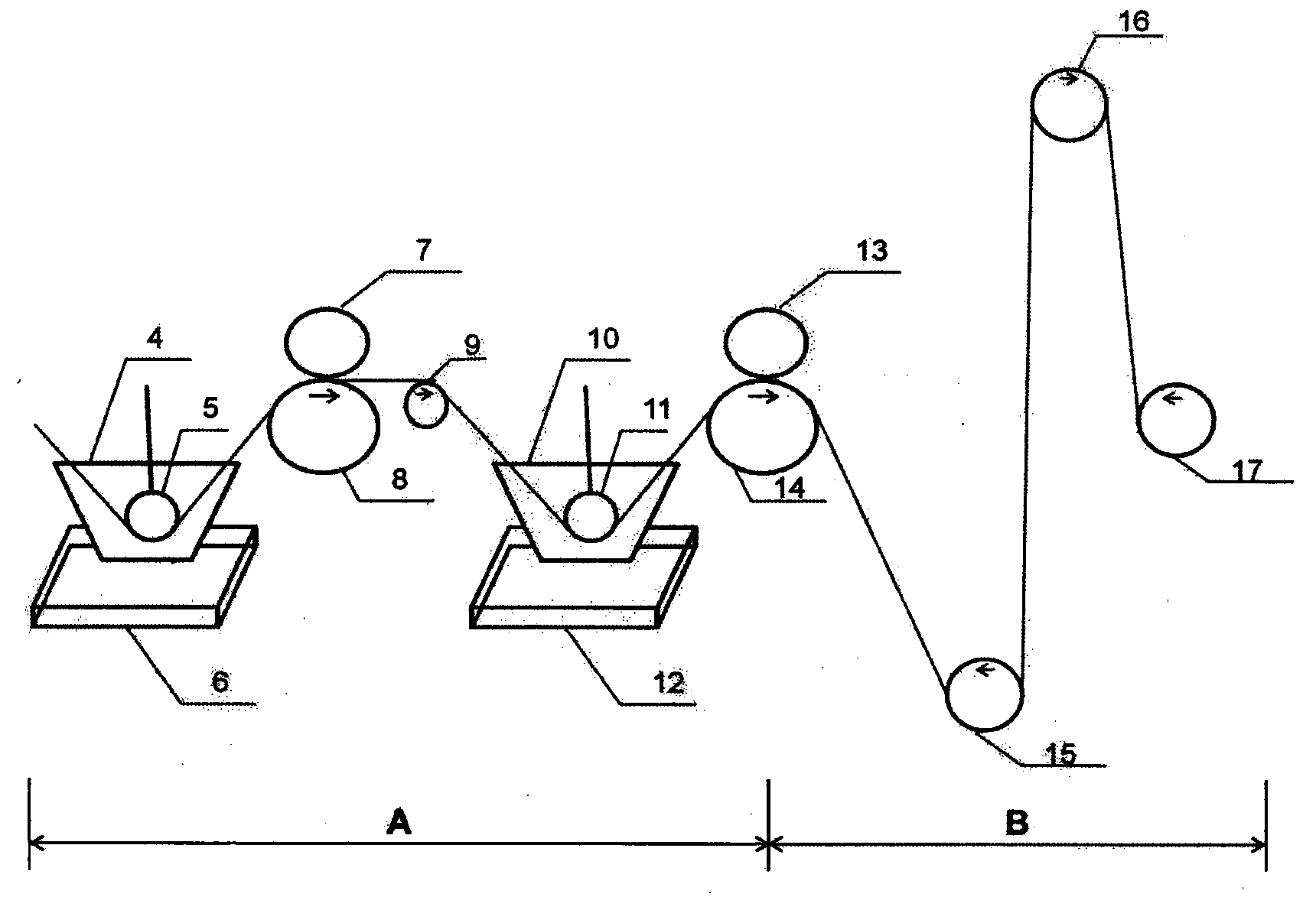

[0030] like figure 2Shown is a schematic diagram of the structure of the coating device. The coating device is composed of a coating area A and a drying area B. The coating area A is at least provided with a dipping tank 4, a first dipping roll 5, a first Heating device 6, first pressure roller, first guide roller 9, immersion tank 10, second impregnation roller 11, second heating device 12 and second pressure roller, at least a second guide roller is provided in the drying area B 15. The third guide roller 16 and the drum 17; the first impregnating roller 5 and the second impregnating roller 11 are respectively arranged in the dipping tank 4 and the immersion tank 10, and the dipping tank 4 and the immersion tank 10 are respectively arranged in the first heating device 6 and the On the second heating device 12, the first pressure roller is made up of the first rubber roller 7 and the first stainless steel roller 8 arranged thereunder, the first pressure roller is arranged be...

Embodiment 2

[0040] Such as figure 2 Shown is a schematic diagram of the structure of the coating device. The coating device is composed of a coating area A and a drying area B. The coating area A is at least provided with a dipping tank 4, a first dipping roll 5, a first Heating device 6, first pressure roller, first guide roller 9, immersion tank 10, second impregnation roller 11, second heating device 12, and second pressure roller, and at least a second guide roller is provided in the drying area B. Roller 15, third guide roller 16 and drum 17; the first impregnating roller 5 and the second impregnating roller 11 are respectively arranged in the dipping tank 4 and the immersion tank 10, and the dipping tank 4 and the immersion tank 10 are respectively arranged in the first heating device 6 And on the second heating device 12, the first pressure roller is made up of the first rubber roller 7 and the first stainless steel roller 8 arranged thereunder, the first pressure roller is arrang...

Embodiment 3

[0050] Such as figure 2 Shown is a schematic diagram of the structure of the coating device. The coating device is composed of a coating area A and a drying area B. The coating area A is at least provided with a dipping tank 4, a first dipping roll 5, a first Heating device 6, first pressure roller, first guide roller 9, immersion tank 10, second impregnation roller 11, second heating device 12, and second pressure roller, and at least a second guide roller is provided in the drying area B. Roller 15, third guide roller 16 and drum 17; the first impregnating roller 5 and the second impregnating roller 11 are respectively arranged in the dipping tank 4 and the immersion tank 10, and the dipping tank 4 and the immersion tank 10 are respectively arranged in the first heating device 6 And on the second heating device 12, the first pressure roller is made up of the first rubber roller 7 and the first stainless steel roller 8 arranged thereunder, the first pressure roller is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com