Vertical numerical-control deep hole drilling machine

A deep hole drilling machine, vertical technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of low precision, many auxiliary man-hours, drilling string vibration, etc., to achieve Convenient positioning and alignment, less auxiliary man-hours, and satisfactory drilling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

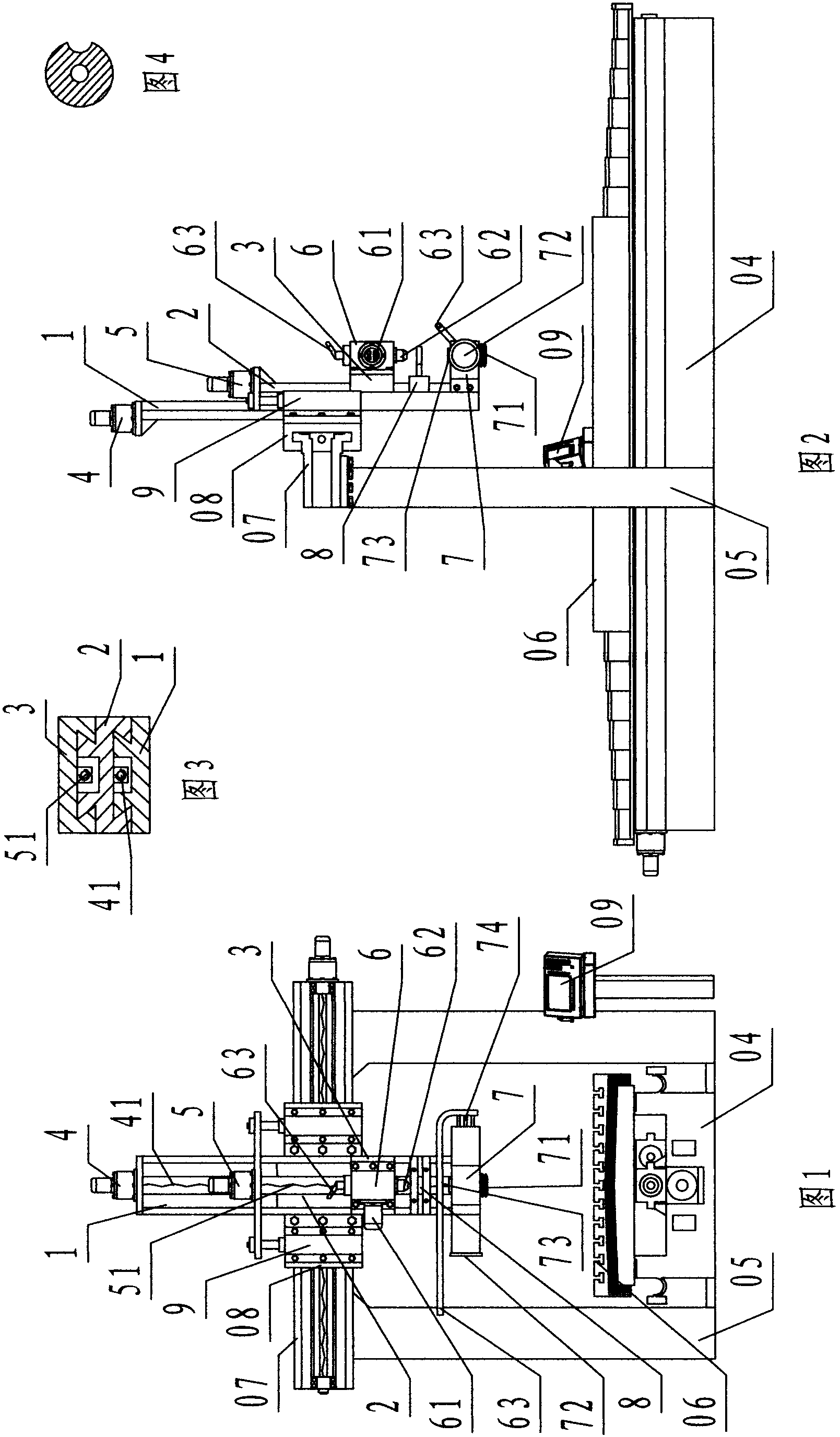

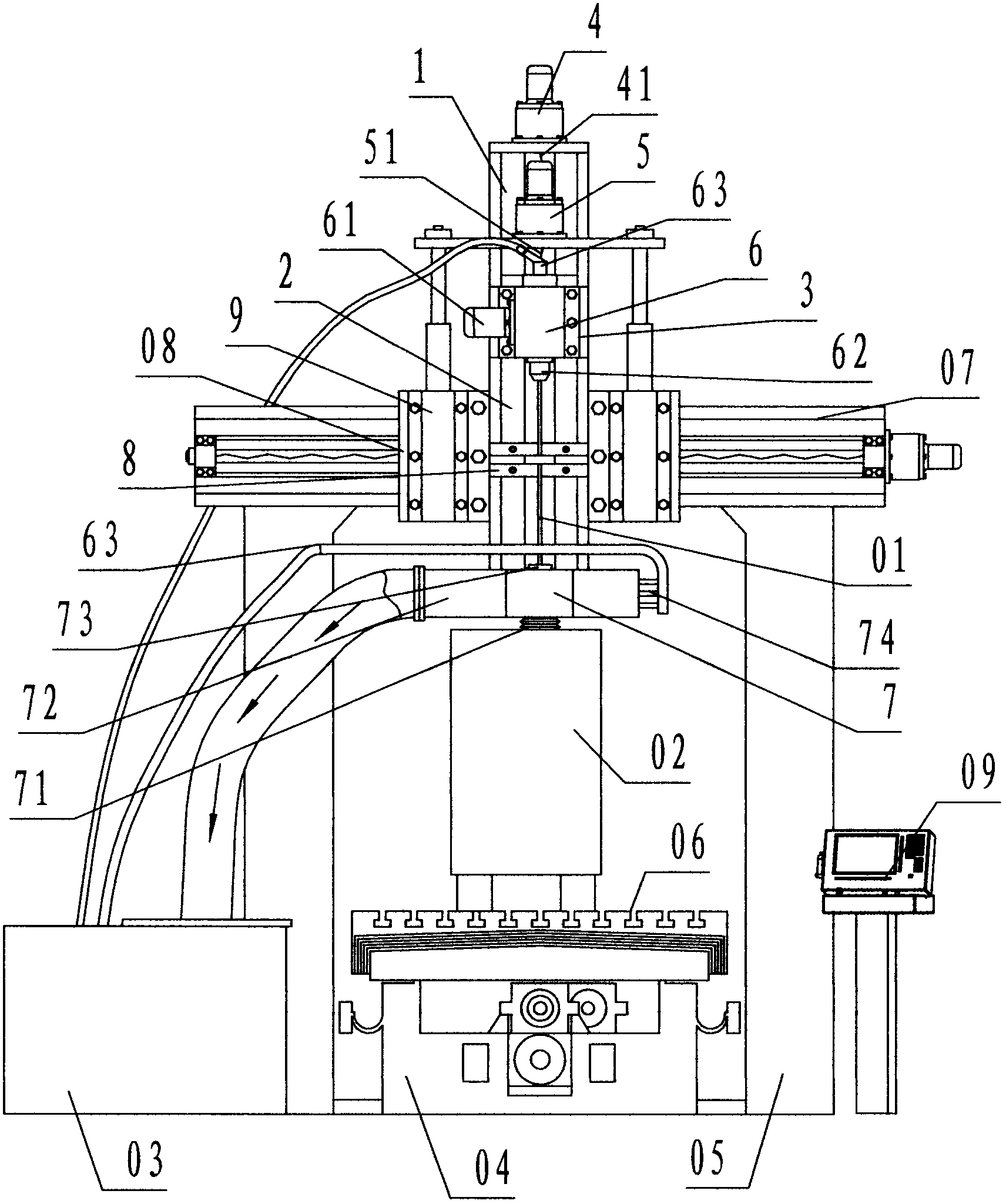

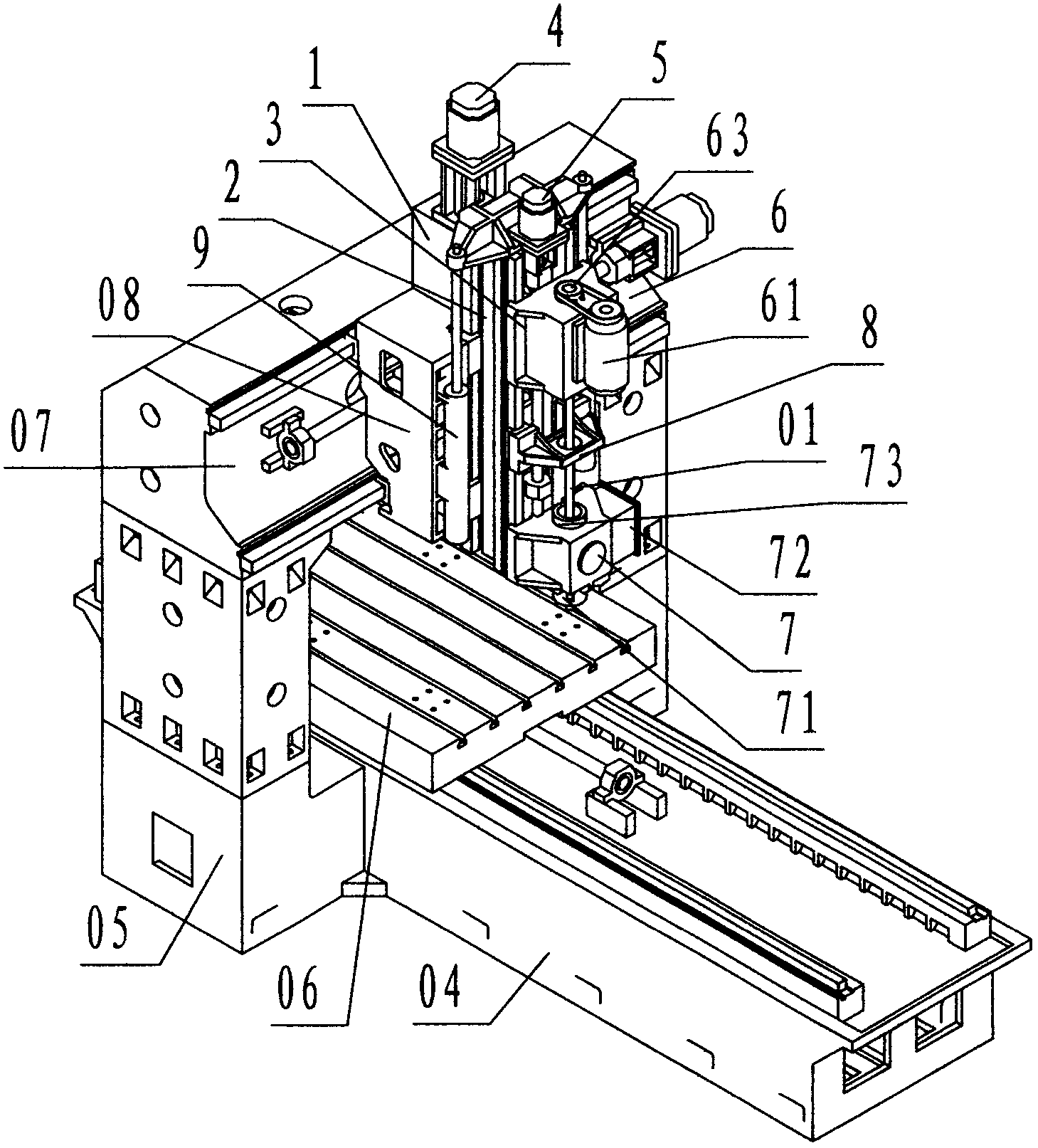

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , a kind of vertical numerical control deep hole drilling machine of the present invention, comprises fixed guide rail 1, moving guide rail 2, Z carriage 3, moving rail feeding motor 4, moving rail feeding screw rod 41, Z board feeding motor 5, Z Plate feed screw 51, drilling rig box 6, positioning chip removal compactor 7, drill pipe center frame 8, hydraulic stabilizer 9, deep hole drill bit 01, wherein: the fixed guide rail 1 is a long rectangular member, one side It is a guide rail with a rectangular long groove running through both ends in the middle, and the other side is a flat plate, with an assembly platform on the upper end and an open lower end; the moving guide rail 2 is a long rectangular member, and one side is provided with a rectangular long groove running through both ends in the middle The other side of the guide rail is a guide rail groove and the middle part of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com