Plain concrete wall surface groove type three-dimensional wood grains decoration construction method

A technology for decorative construction and fair-faced concrete, which is applied in the direction of construction, building structure, and building material processing, and can solve problems such as unfavorable construction schedules, quality, cost control, time-consuming, and high maintenance costs, and achieve energy and resource saving and reduction Effects of environmental pollution and reduction of labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

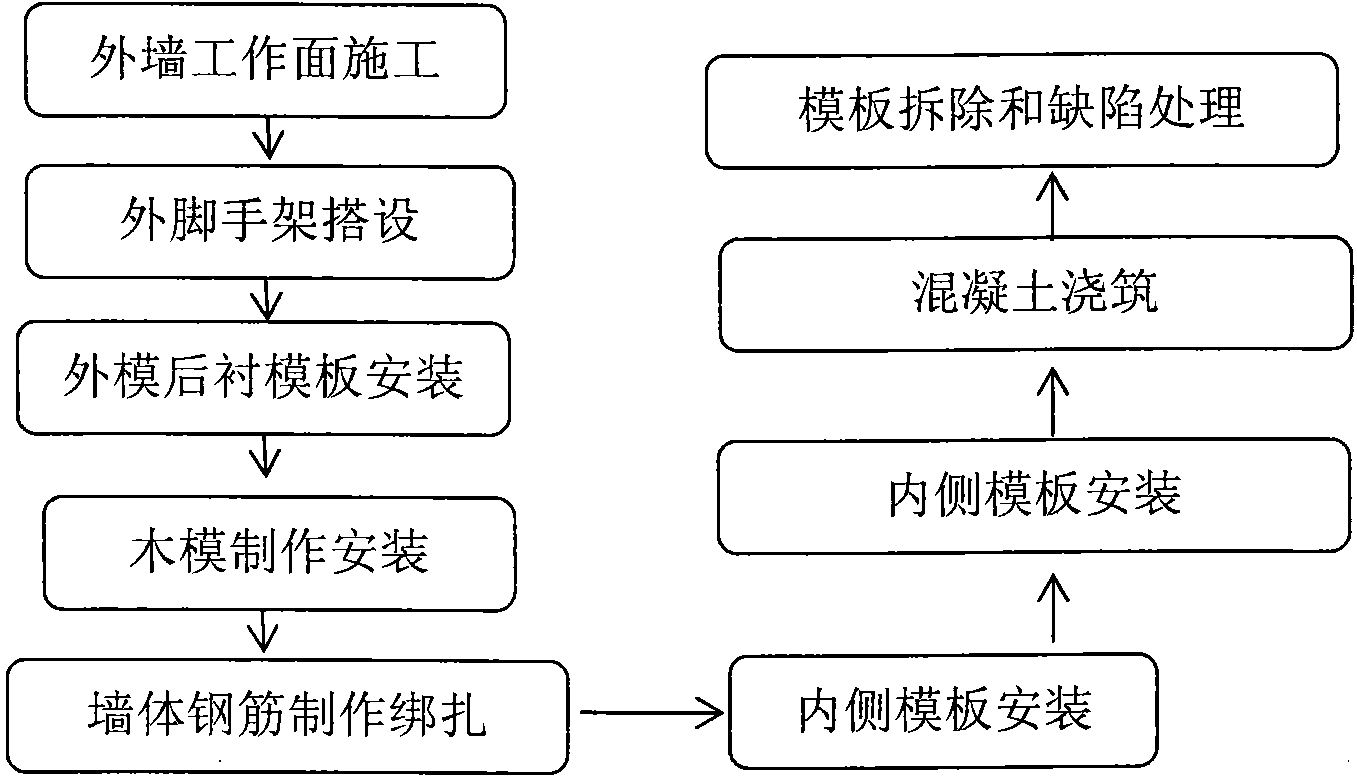

[0035] Construction method operation steps are as follows in the present embodiment:

[0036] ①Construction of the working surface of the external wall and setting of the support system;

[0037] Within the range of 4m from the outside of the building to the outside of the wall, the site will be hardened for the erection of external support scaffolding. At the same time, in order to ensure the stability of the horizontal direction of the concrete external scaffolding, the distance from the outside of the bottom plate to 1.5m and Ф20mm "Ω" type ground anchors are set at the position of 3m, and the distance between the ground anchors along the wall is 2m. The force component in the direction of the wall must be shared by the scaffolds on both sides of the wall, the inclined side support bears the pressure, and the other side supports bear the tensile stress. Four rows of scaffolding are set up on the outside of the wall, and a full house of scaffolding is set up on the inside; ...

Embodiment 2

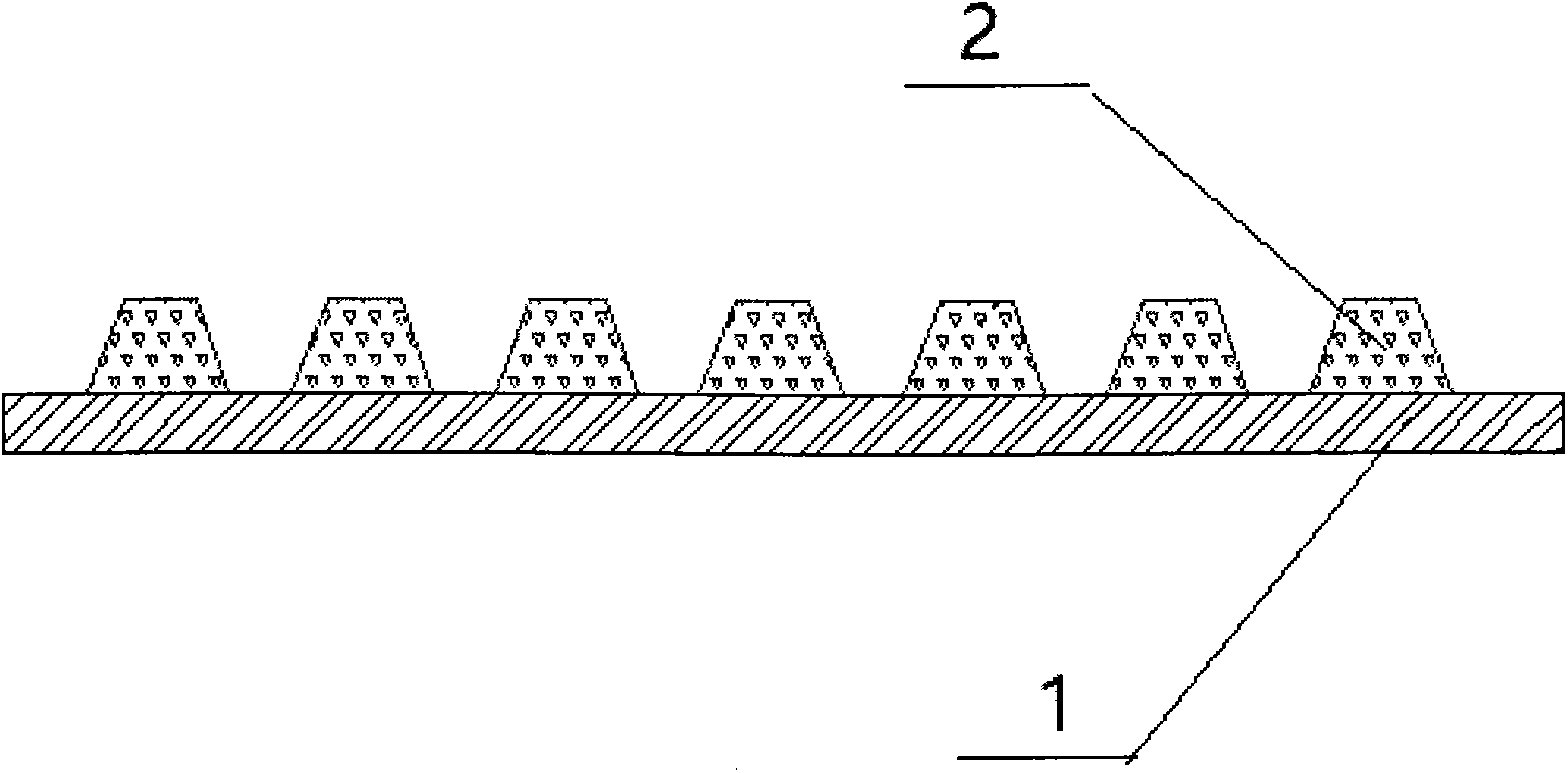

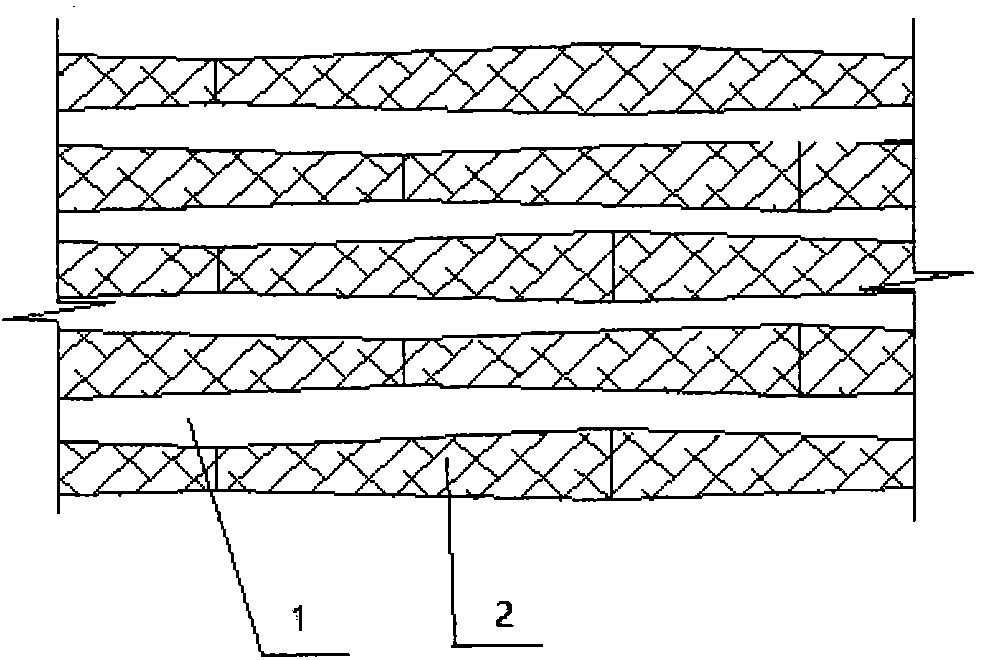

[0053] as attached image 3 As shown, the convex wood strip 2 is the longest in the length direction, and the end of the strip-shaped bamboo mold of 3m is continued to be a bamboo mold joint with a diameter of 8cm or 10cm. The convex wooden strip 2 is pierced and fixed on the 18mm thick backing Mirror panel 1.

[0054] as attached Figure 4 Shown, convex wooden bar 2 is the bamboo mold that outer edge is the arcuate section.

[0055] In the embodiment of the present invention, the key points of concrete pouring, vibrating and maintenance operations are as follows:

[0056] ① When pouring concrete, strictly control the time of concrete layered pouring to ensure that the cement mortar attached to the surface of the bamboo formwork in the lower layer has not yet set when the upper layer is poured. Temporary shielding should be carried out, and the cement slurry attached to the surface of the wooden formwork should be removed in time after the concrete pouring is completed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com