Solar heat storage device across seasons

A heat storage device and cross-season technology, applied in the field of solar energy storage, can solve the problems of reduced thermal efficiency of the system, long heat storage period, heat reduction, etc. The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

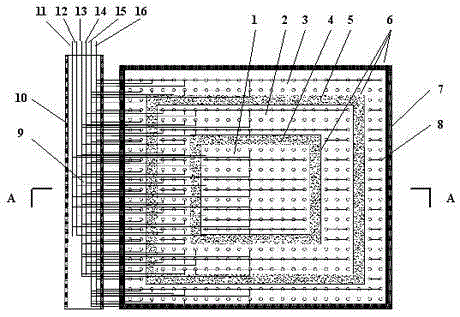

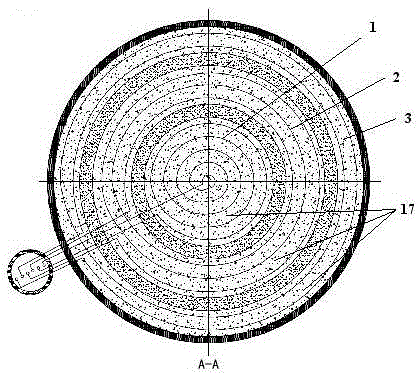

[0025] Such as figure 1 , figure 2 As shown, the heat storage medium 17 is a solid heat storage medium formed by uniformly mixing water, soil, and sand in a certain proportion. , one of the five shapes of a cylinder with a dome at both ends, a sphere, and a cylindrical-conical combination. The heat storage body is surrounded by a heat-insulating layer 7, and a waterproof layer 6 is provided inside and outside the heat-insulating layer 7. The heat storage body is divided into three independent parts. The three heat storage areas are sequentially separated by the first heat insulation layer 4 and the second heat insulation layer 5, and each heat insulation layer is provided with a waterproof layer 6 on both sides, and the heat exchanger is a horizontally layered heat exchanger. Heat pipes 8, each layer of heat exchange pipes 8 is a spiral involute layout that gradually expands from the center to the edge. The heat exchange pipes 8 in different heat storage areas in the same la...

Embodiment 2

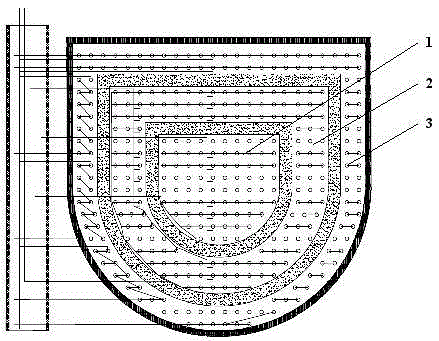

[0038] On the basis of Example 1, the figure 1 The shape of the cylindrical heat storage body in is changed to the shape of a cylindrical single hemisphere combined with a short cylinder and a half sphere, such as image 3 As shown, embodiment 2 has just been formed. The heat insulation layer 4 of Example 2 is also in the shape of a cylindrical single hemispherical combination, and the connection mode of the heat exchange tubes is similar to that of Example 1. It should be noted that: under the condition of the same volume of heat storage medium, this cylindrical single hemispherical combination has a smaller surface area than a cylinder, and has less heat storage heat loss. Each independent spiral heat exchange tube has the same length, and its connection method is also relatively complicated.

Embodiment 3

[0040] On the basis of Example 1, the figure 1 The shape of the cylindrical heat storage body is changed to the shape of a short cylinder combined with two hemispheres, such as Figure 4 As shown, embodiment 3 has just been formed. The heat insulation layer 4 of Example 3 is also in the shape of a combination of two hemispheres of a cylinder, and the connection method of the heat exchange tubes is similar to that of Example 1. It should be noted that, in the case of the same volume of heat storage medium, the combination of two hemispheres of the cylinder has a smaller surface area than the combination of the cylinder and the single hemisphere of the cylinder, and the heat loss of heat storage is also less, but the two hemispheres The construction technology is relatively high, and the length of each independent spiral heat exchange tube must be guaranteed to be equal, and the connection method is also relatively complicated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com