Epitaxial growth method for improving electrostatic endurance capacity of GaN-based light-emitting diode (LED)

An epitaxial growth and static electricity technology, which is applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of device antistatic ability, LED chip leakage, ESD, electrical performance, uneven current distribution, etc., to achieve Effect of Improving ESD Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

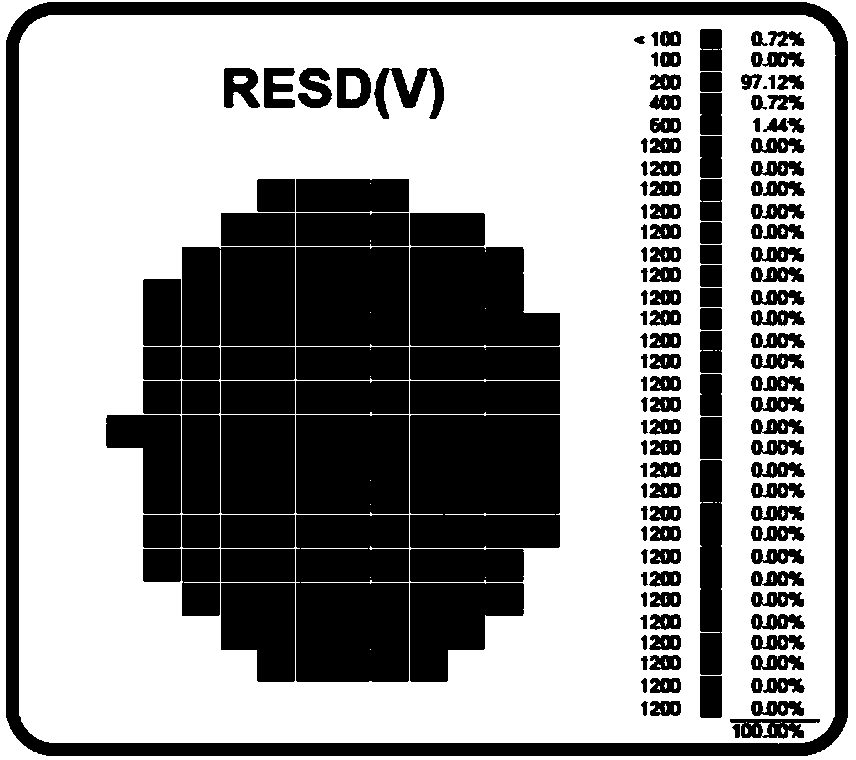

Embodiment 1

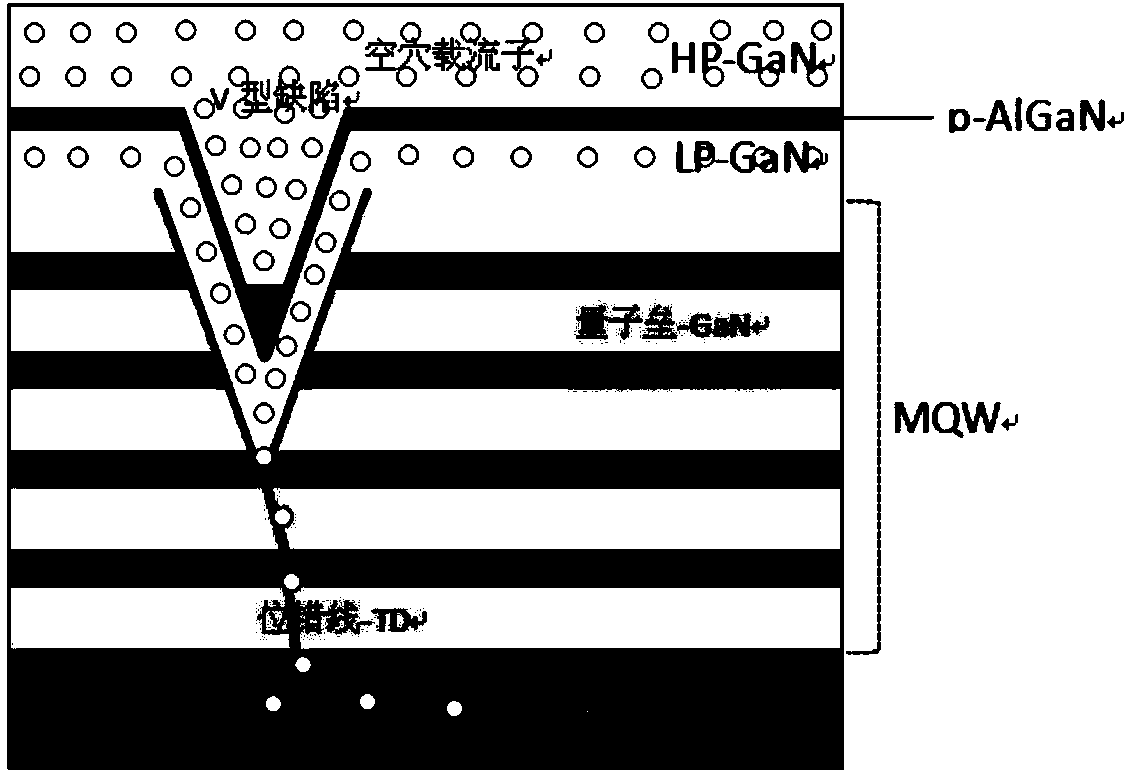

[0028]An epitaxial growth method for improving the electrostatic tolerance of GaN-based LEDs. The LED epitaxial structure includes, from bottom to top, a sapphire substrate, a low-temperature nucleation layer, a high-temperature GaN buffer layer, a high-temperature u-GaN layer, and an n-type GaN layer. layer, shallow quantum well structure SW, low-doped n-GaN electrostatic neutralization layer EN, multi-quantum well light-emitting layer structure MQW, low-temperature p-type GaN layer, p-type AlGaN layer, high-temperature p-type GaN layer, p-type contact layer, Its preparation method comprises the following specific steps:

[0029] (1) Anneal the sapphire substrate in a hydrogen atmosphere, clean the substrate surface at a temperature of 1050°C, and then perform nitriding treatment;

[0030] (2) Lower the temperature to 500°C and grow a 25nm-thick low-temperature GaN nucleation layer with a growth pressure of 400Torr and a molar ratio of V / III of 500;

[0031] (3) After the gr...

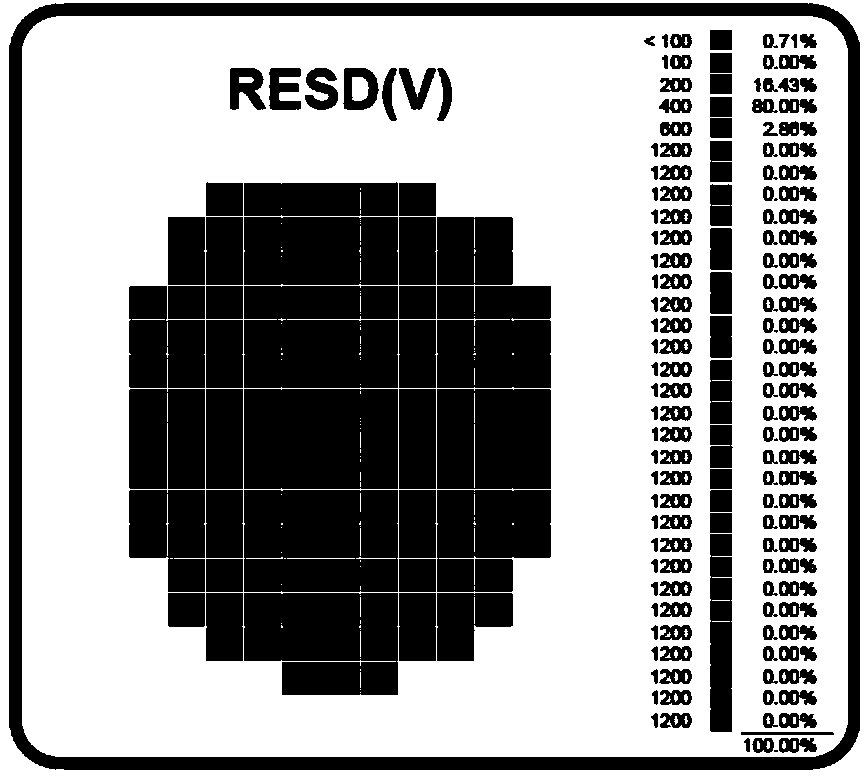

Embodiment 2

[0044] An epitaxial growth method for improving the electrostatic tolerance of GaN-based LEDs. The LED epitaxial structure includes, from bottom to top, a sapphire substrate, a low-temperature nucleation layer, a high-temperature GaN buffer layer, a high-temperature u-GaN layer, and an n-type GaN layer. layer, shallow quantum well structure SW, low-doped n-GaN electrostatic neutralization layer EN, multi-quantum well light-emitting layer structure MQW, low-temperature p-type GaN layer, p-type AlGaN layer, high-temperature p-type GaN layer, p-type contact layer, Its preparation method comprises the following specific steps:

[0045] (1) Anneal the sapphire substrate in a hydrogen atmosphere, clean the substrate surface at a temperature of 1150°C, and then perform nitriding treatment;

[0046] (2) Lower the temperature to 620°C, grow a 40nm-thick low-temperature GaN nucleation layer, the growth pressure is 650Torr, and the V / III molar ratio is 3000;

[0047] (3) After the growt...

Embodiment 3

[0060] An epitaxial growth method for improving the electrostatic tolerance of GaN-based LEDs. The LED epitaxial structure includes, from bottom to top, a sapphire substrate, a low-temperature nucleation layer, a high-temperature GaN buffer layer, a high-temperature u-GaN layer, and an n-type GaN layer. layer, shallow quantum well structure SW, low-doped n-GaN electrostatic neutralization layer EN, multi-quantum well light-emitting layer structure MQW, low-temperature p-type GaN layer, p-type AlGaN layer, high-temperature p-type GaN layer, p-type contact layer, Its preparation method comprises the following specific steps:

[0061] (1) Anneal the sapphire substrate in a hydrogen atmosphere, clean the surface of the substrate at a temperature of 1100°C, and then perform nitriding treatment;

[0062] (2) Lower the temperature to 520°C to grow a 30nm-thick low-temperature GaN nucleation layer with a growth pressure of 450Torr and a molar ratio of V / III of 2000;

[0063] (3) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com