Electrolyte for lithium ion batteries

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems affecting battery life, negative electrode SEI film rupture, and deterioration of battery performance, and achieve the effects of slowing down capacity decay, inhibiting dissolution, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

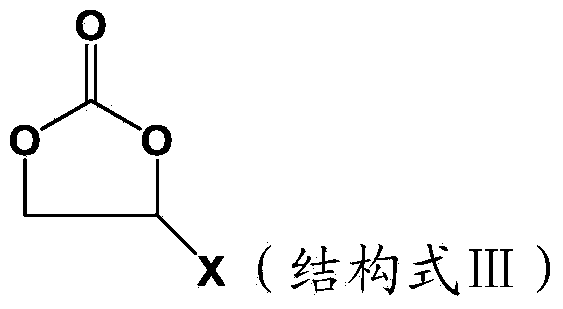

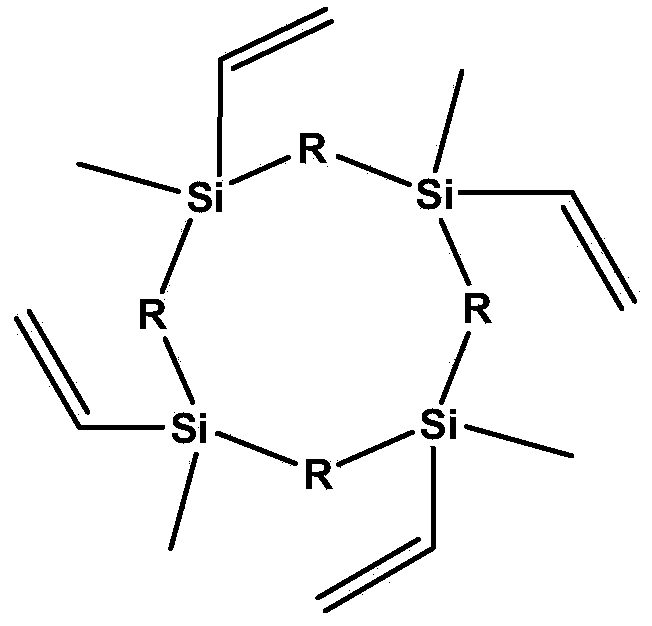

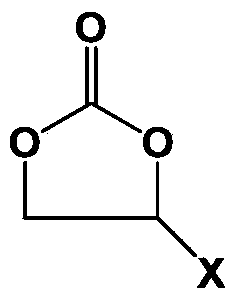

Embodiment 1

[0031] The electrolyte is prepared in a glove box with a dew point controlled below -40°C. The configuration process is as follows: the weight ratio of ethylene carbonate (EC), propylene carbonate (PC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) is EC:PC:EMC:DEC=25:5: Mix at 50:20, and then add lithium hexafluorophosphate to prepare a 1M (M is mol / L) electrolyte; and add 1% (by mass, the same below) tetramethyltetravinylcyclotetrasiloxane to it, After fully stirring and mixing uniformly, the desired electrolyte solution is obtained.

Embodiment 2

[0039] The electrolyte preparation method is the same as in Example 1, except that tetramethyltetravinylcyclotetrasiloxane is replaced by tetramethyltetravinylcyclotetrasilazane.

Embodiment 3

[0041] The preparation method of the electrolyte is the same as that of Example 1, except that 0.05% tetramethyltetravinylcyclotetrasiloxane is added to the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com