Amine-free voc-free metal working fluid

A metal processing, emulsion technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., to achieve low foaming, good stability, and environmental friendliness.

Inactive Publication Date: 2014-05-28

CHEMETALLGMBH

View PDF6 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, disadvantages of existing synthetic metalworking compositions are typically problems with cleaning residues caused by added lubricity additives, reduced lubricity when compared with petroleum oil-based products on the same cost basis, increased Oil sump life and machine maintenance corrosion issues, and potential skin irritation to workers

But certain levels of petroleum oils in any metalworking composition cause several problems: 1.) Poor thermal conductivity so that it has a lower cooling effect, 2.) It allows microorganisms to grow and can be harmful to workers, 3. ) petroleum oils cause mist and residues that are difficult to wash off, 4.) disposal issues and are not environmentally friendly and 5.) water hardness can affect emulsion stability

In recent years, several amine-containing metalworking compositions have been used because amines and especially alkanolamines are helpful in antibiological action, corrosion protection and emulsion stability, but several amines are very toxic and also incorporate volatile Sexual organic compound VOC

Formation of aqueous metalworking compositions without the use of any amines is more difficult

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

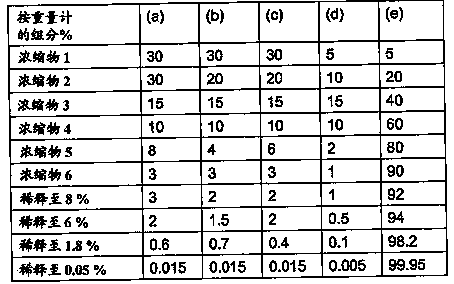

[0196] Examples and Comparative Examples

[0197] The present invention may be appreciated in further detail by consideration of the following examples, including preferred embodiments, which are not intended to limit the invention in any way.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| water solubility | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

Login to View More

Abstract

The present application concerns an aqueous metalworking composition comprising in a concentrate or after dilution of a concentrate with water in a diluent: 0.002 to 40 % by weight of component (a) which is a lubricity agent comprising at least one water-insoluble compound (a) having at least one hydrophobic aliphatic chain and at least one polar group and having a water solubility at 20 DEG C of less than 0.1 g / liter; 0.002 to 40 % by weight of component (b)comprising at least one water-soluble corrosion inhibiting compound(b) having a water-solubility at 20 DEG C of more than 0.1g / liter; 0.002 to 45 % by weight of at least one emulsifying and dispersing agent(c)which contains at least one emulsifying and / or dispersing compound (c) which is water-soluble, water-miscible or water-dispersable and which is selected from the group consisting of non-ionic, anionic and zwitterionic surfactants; 0.002to 30 % by weight of an alkalinity agent (d) containing at least one alkaline water-soluble compound (d) selected from the group consisting of hydroxides and carbonates; and 0.004 to 99 % by weight of a transport component(e)containing predominantly water. Further on, the present application concerns a method of use of such aqueous metalworking composition as a coolant, as a lubricant, etc., and concerns further on a method to prepare an aqueous metalworking composition and a metalworking process.

Description

[0001] This invention relates to the field of water-based metalworking compositions. technical field [0002] In particular, the present invention relates to aqueous, environmentally friendly, recyclable, synthetic, amine-free, petroleum oil-free and voc-free metalworking compositions that are highly harmless materials and compatible with a wide range of compatible metal alloys. Background of the invention [0003] Metalworking compositions are used in many metalworking operations such as cutting, grinding, forming, lapping, drawing, forming, pressing, punching, rolling, embossing, and otherwise lubricating and cooling metalworking tools, to flush metallic debris and impurities from the workpiece (if some are present), and to protect, as far as possible, the components of the tool and machine from damage, wear and corrosion. Such treatments include cutting operations exhibiting metal removal, such as grinding, turning, milling, tapping, broaching, and gear hobbing, and for...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M173/02

CPCC10M173/02C10M2207/129C10M2217/045C10M2219/042C10M2205/022C10N2240/405C10M2209/103C10M2207/126C10N2270/02C10M2209/084C10M2207/289C10M133/44C10M2217/044C10N2240/402C10N2220/028C10M2217/024C10M2219/104C10M2221/04C10M2207/127C10M2209/106C10N2210/02C10N2240/401C10M2201/087C10M2227/061C10N2230/12C10N2220/027C10M2207/023C10M2215/04C10M2209/12C10M2207/021C10M2205/028C10M2209/104C10N2240/404C10M2215/223C10M2215/224C10M2207/125C10N2230/06C10N2270/00C10M2223/04C10N2240/40C10M2207/022C10M2209/102C10N2230/24C10M2201/062C10M2205/026C10M2209/105C10M2207/40C10N2010/04C10N2020/069C10N2020/071C10N2030/06C10N2030/12C10N2030/24C10N2040/20C10N2040/22C10N2040/24C10N2040/242C10N2040/243C10N2070/00C10N2070/02C10N2010/02

Inventor Y.赵

Owner CHEMETALLGMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com