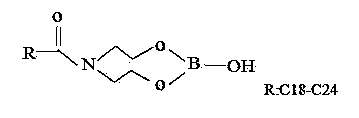

Tall oil acid diacetyl amide borate and preparation method thereof

A technology of tall oleic acid diacetamide borate and tall oil fatty acid, which is applied in the field of tall oleic acid diacetamide borate and its preparation, and can solve the problem of reduced lubricity and rust resistance, and resistance to hard water, etc. problems, achieve the effects of reducing friction and bonding, isolating corrosion, and excellent corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

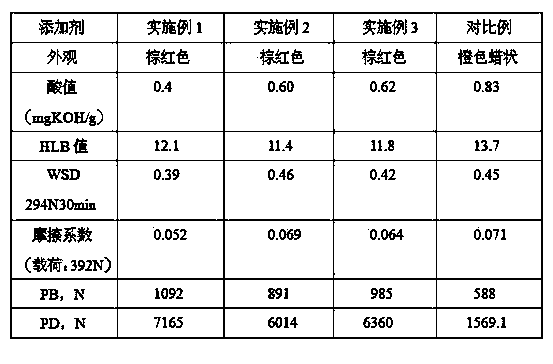

Embodiment 1

[0027] Example 1: Tall oil diacetamide borate comprises tall oil fatty acid, diethanolamine, boric acid, and potassium hydroxide.

[0028] Tall oleic acid is DXTO-50 industrial grade produced by Dexu Chemicals. Diethanolamine is industrial grade imported from Dow in the United States. Boric acid is industrial grade imported from Sanxiang in the United States. Potassium hydroxide is Axi pharmaceutical grade in the United States.

[0029] The preparation method of tall oleic acid diacetamide borate of the present invention is divided into the following steps:

[0030] The components are as follows: tall oil fatty acid 55%, diethanolamine 33%, boric acid 10%, potassium hydroxide 2%.

[0031] (1) Put the tall oil fatty acid into the reaction kettle and raise the temperature to 140°C for later use;

[0032] (2) Divide the diethanolamine into two equal parts, one part is slowly put into the reaction kettle, and the other part is reserved.

[0033] (3) Put potassium hydroxide into ...

Embodiment 2

[0039] Embodiment 2: tall oleic acid diacetamide borate of the present invention is made up of following each component: tall oil fatty acid 45%, diethanolamine 43%, boric acid 10.2%, potassium hydroxide 1.8%.

[0040] The preparation method of tall oleic acid diacetamide borate of the present invention is divided into the following steps:

[0041] The components are as follows: tall oil fatty acid 45%, diethanolamine 43%, boric acid 10.2%, potassium hydroxide 1.8%.

[0042] (1). Put the tall oil fatty acid into the reaction kettle and raise the temperature to 130°C for standby;

[0043] (2). Divide the diethanolamine into two equal parts, put one part into the reaction kettle slowly, and keep the other part for later use.

[0044] (3). Put potassium hydroxide into the reaction kettle, raise the temperature to 150°C, and react for 2 hours.

[0045] (4). Titrate the contents of the reactor for acid value detection, and put in another portion of diethanolamine until the acid v...

Embodiment 3

[0049] Embodiment 3: Tall oil diacetamide borate comprises tall oil fatty acid, diethanolamine, boric acid, p-toluenesulfonic acid. Tall oleic acid is DXTO-50 industrial grade produced by Dexu Chemicals. Diethanolamine is industrial grade imported from Dow in the United States. Boric acid is industrial grade imported from Sanxiang in the United States. P-toluenesulfonic acid is industrial grade from Shandong.

[0050] The preparation method of tall oleic acid diacetamide borate of the present invention is divided into the following steps:

[0051] The components are as follows: tall oil fatty acid 50%, diethanolamine 38%, boric acid 9.5%, p-toluenesulfonic acid 2.5%.

[0052] (1). Put the tall oil fatty acid into the reaction kettle and raise the temperature to 135°C for later use;

[0053](2). Divide the diethanolamine into two equal parts, put one part into the reaction kettle slowly, and keep the other part for later use.

[0054] (3). Put p-toluenesulfonic acid int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com