Method for manufacturing substrate with built-in component and substrate with built-in component using same

A technology with a built-in substrate and a manufacturing method, which is applied in the manufacturing of electrical components, electrical components, printed circuits, etc., can solve problems affecting the formation of conductive vias, connection reliability, insulation, etc., to improve heat resistance and reliability. , the effect of reducing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

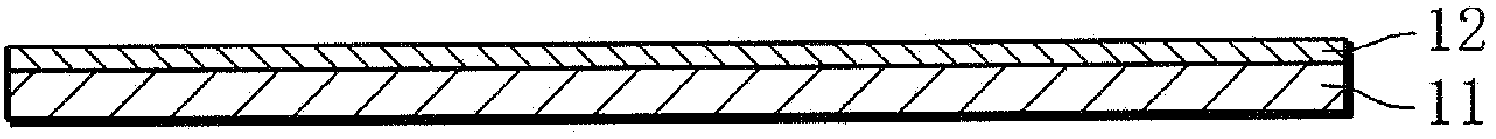

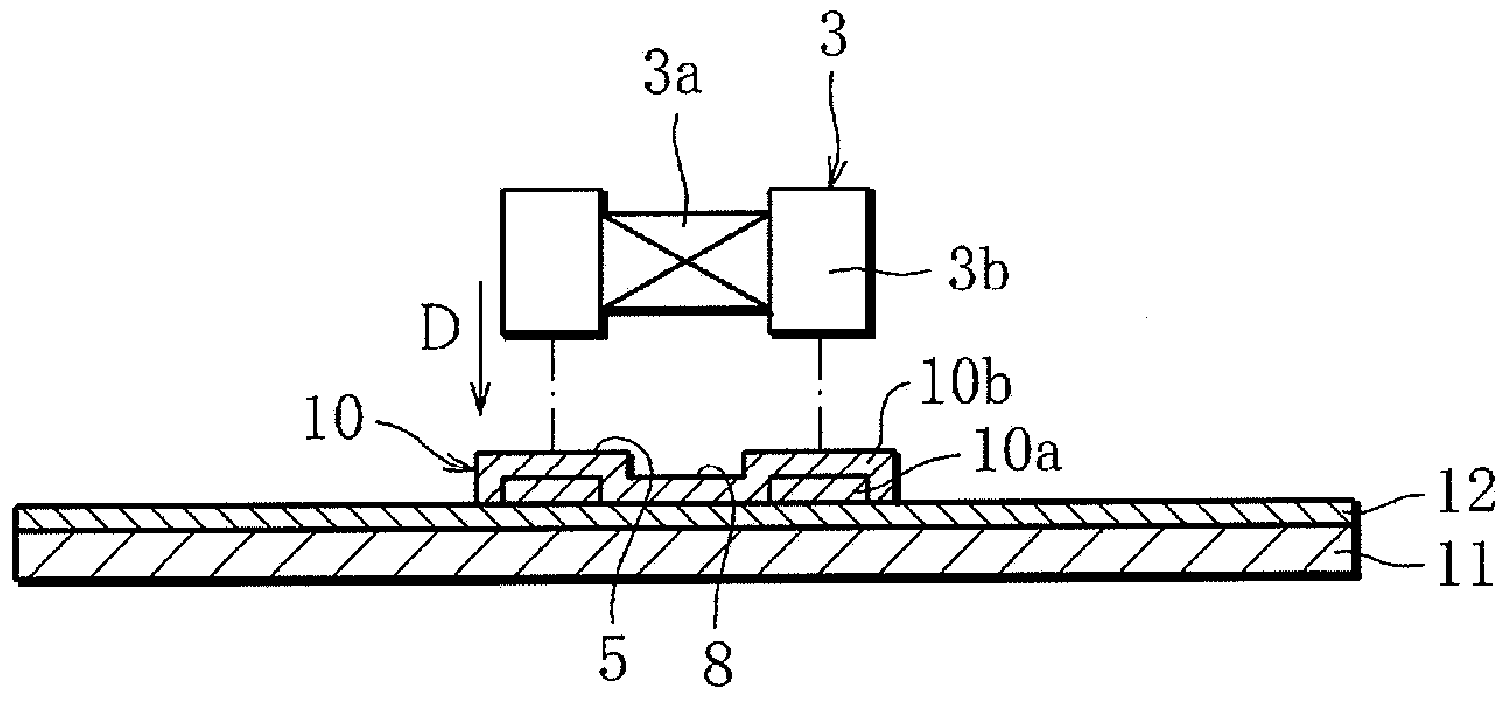

[0041] Such as Figure 1 ~ Figure 3 As shown, the method of manufacturing a component-embedded substrate according to the present invention first performs an adhesive layer forming step. Such as figure 1 As shown, in this step, for example, a member in which the metal layer 12 is formed on the support plate 11 is first prepared. In addition, the support plate 11 has a degree of rigidity required by process conditions. The support plate 11 is formed of a rigid SUS (stainless steel) plate, an aluminum plate, or the like as a support base material. For example, when the support plate 11 is a SUS plate, the metal layer 12 is deposited copper-plated foil of predetermined thickness. Alternatively, when the support plate 11 is an aluminum plate, the metal layer 12 is copper foil pasted on the support plate 11 .

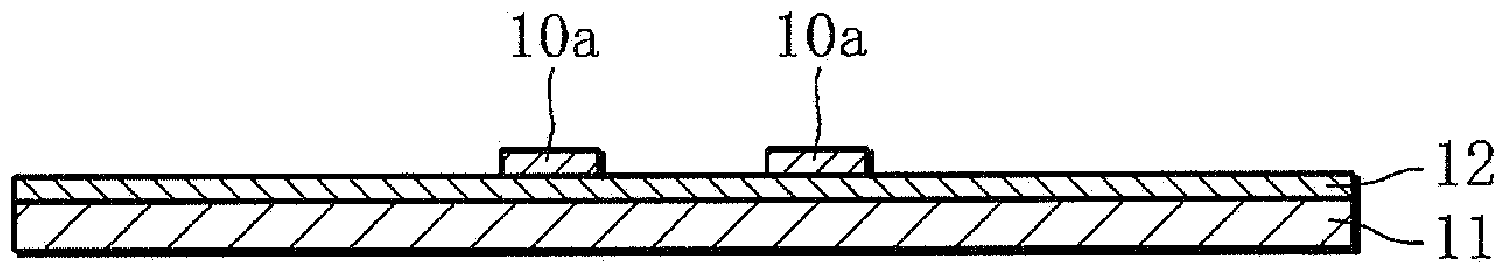

[0042] Then, if figure 2 As shown, the first adhesive body 10 a is coated on the metal layer 12 using, for example, a coater, printing, or the like. Then, after curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com