Welding material for Incone1600 alloy

A technology for welding materials and alloys, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of hidden dangers in the stability and safety of Inconel600 alloy products, unsatisfactory high-temperature mechanical properties of welds, etc. The effect of superior synergistic function, good surface morphology and mechanical properties at room temperature, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

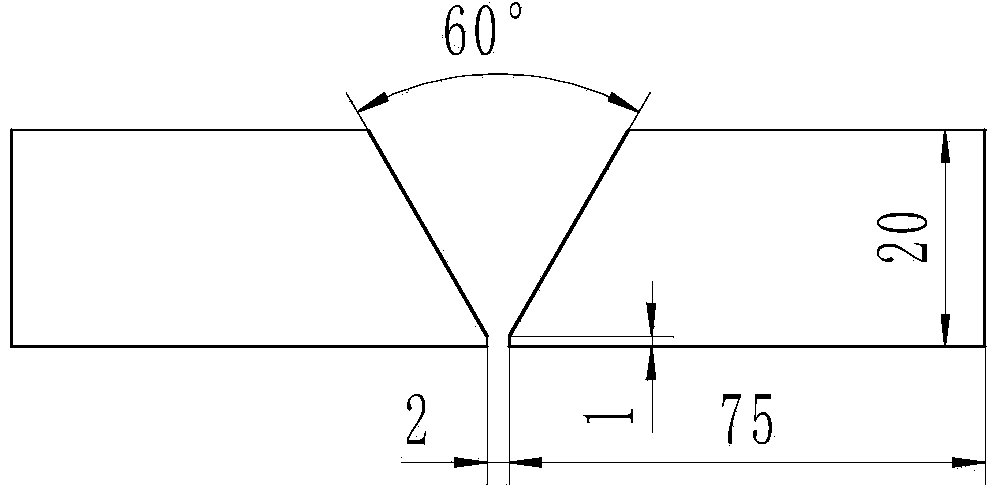

[0021] Two Inconel600 rolled plates with specifications of 450mm×75mm×20mm were selected as welding samples, and a V-shaped butt joint groove was adopted. The groove type was: the length of the blunt side was 1mm, and the groove angle was 60°. docking structure such as figure 1 shown.

[0022] The above-mentioned welding samples were welded by GTAW welding process; the welding machine model used was WSM-4000 inverter pulse argon arc welding machine; the welding material used was welding wire with a diameter of φ2.4mm, and its composition was: C 0.03% , Cr 16.8%, Fe 7.2%, Mn 0.4%, Nb 2.45%, Si 0.85%, S 0.002%, P 0.002%, Ni balance.

[0023] The connection mode between the welding machine and the welding sample is direct current connection. The welding process includes the following steps:

[0024] (1) Clean the groove surface of the sample to be welded, keep it clean and dry, then connect the groove according to the above-mentioned V-shaped butt joint method, fix the positi...

Embodiment 2

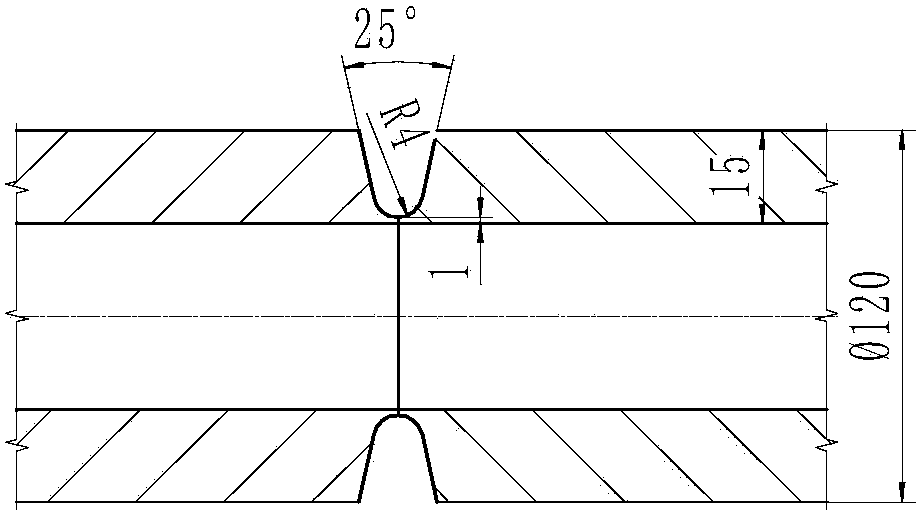

[0028] Two Inconel600 pipe sections with specifications of φ120mm (outer diameter) × 15mm (wall thickness) × 150mm (length) were selected as welding samples, and U-shaped butt joint grooves were adopted. Mouth angle 25°. The docking structure is attached figure 2 shown.

[0029] Using the same welding consumables, equipment and welding process as in Example 1, the above welding samples were welded. The connection mode between the welding machine and the welding sample is direct current connection.

[0030] The welding process includes the following steps:

[0031] (1) Clean the groove surface of the sample to be welded, keep it clean and dry, then connect the groove according to the above U-shaped butt joint method, fix the position by spot welding, and then pass argon gas for protection;

[0032] (2) Carry out bottom welding on the welding sample, the welding current is 90A, the voltage is 12V, the welding speed is about 0.8mm / s, and two layers are welded;

[0033] (3) ...

Embodiment 3

[0034] Embodiment 3 (comparison)

[0035] The welding material in Example 1 was changed to ERNiCr-3 welding wire with a diameter of φ2.4mm, and other conditions remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com