Polyaniline anti-corrosive paint

An anti-corrosion coating, polyaniline technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of large amount of polyaniline, limited promotion and application, easy foaming, etc., and achieve the effect of good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the polyaniline anticorrosion coating described in the application is a method well known to those skilled in the art. As a preferred solution, the preparation method of the polyaniline anticorrosion coating described in the application is specifically:

[0053] Stir the epoxy resin, diluent and phosphoric acid-phosphate ester doped polyaniline for 0.5h to 2h to obtain the first mixture;

[0054] Mixing and stirring the first mixture, additives, fillers and pigments except mica iron oxide, sand-milling and filtering, mixing the obtained filtrate with mica iron oxide, and obtaining component A after stirring;

[0055] Mix component A and component B to obtain polyaniline anticorrosion coating.

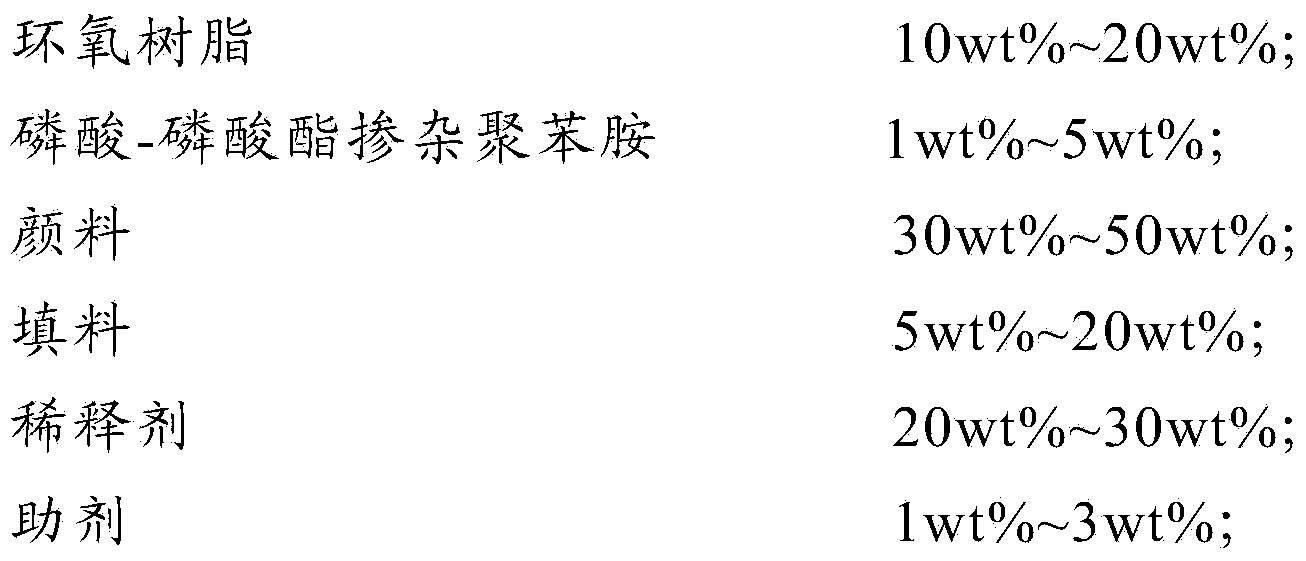

[0056] The application provides a polyaniline anti-corrosion coating, which includes component A and component B, and the component A includes epoxy resin, phosphoric acid-phosphoric acid ester doped polyaniline, pigment, filler, diluent and auxiliary ag...

Embodiment 1

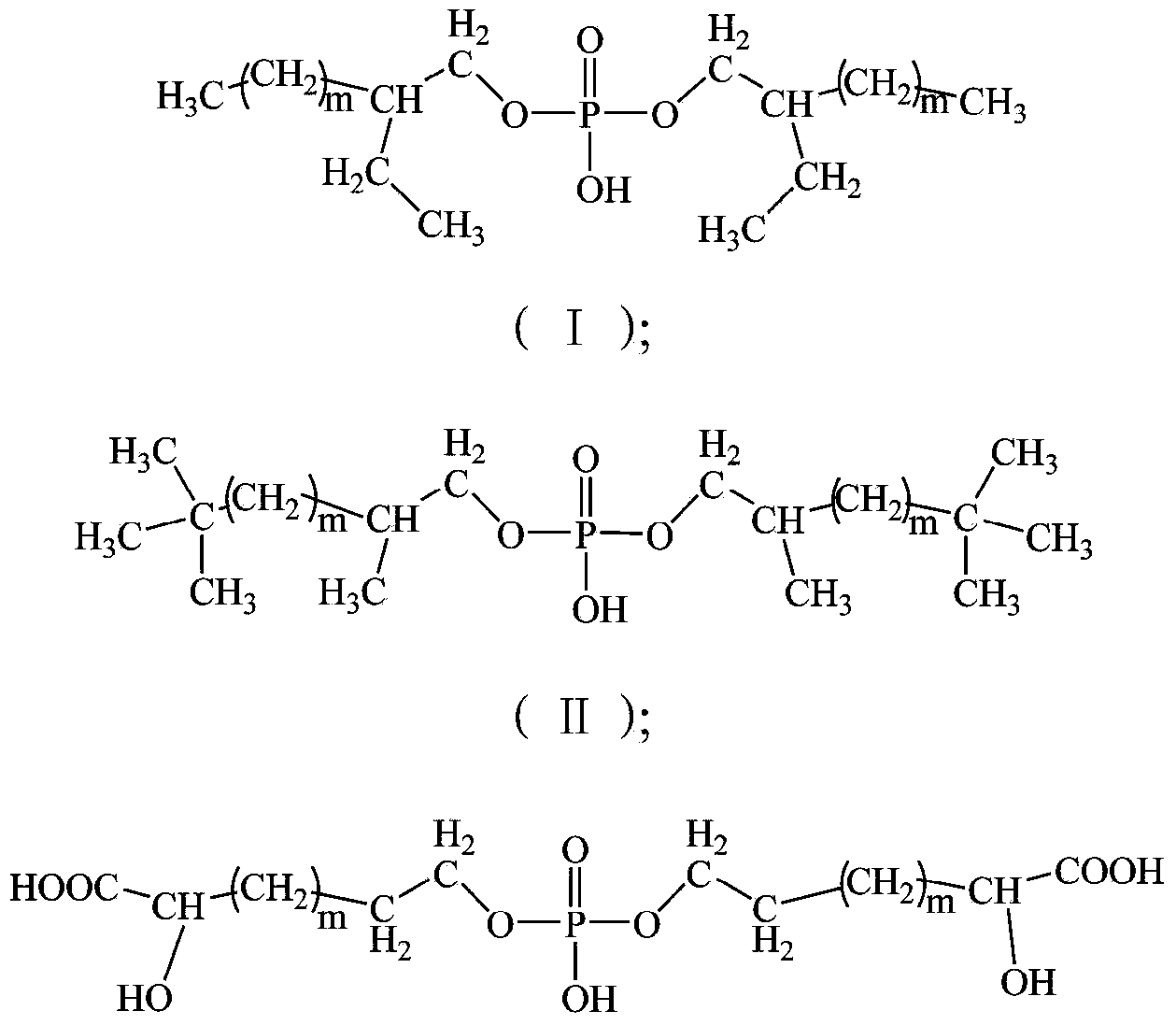

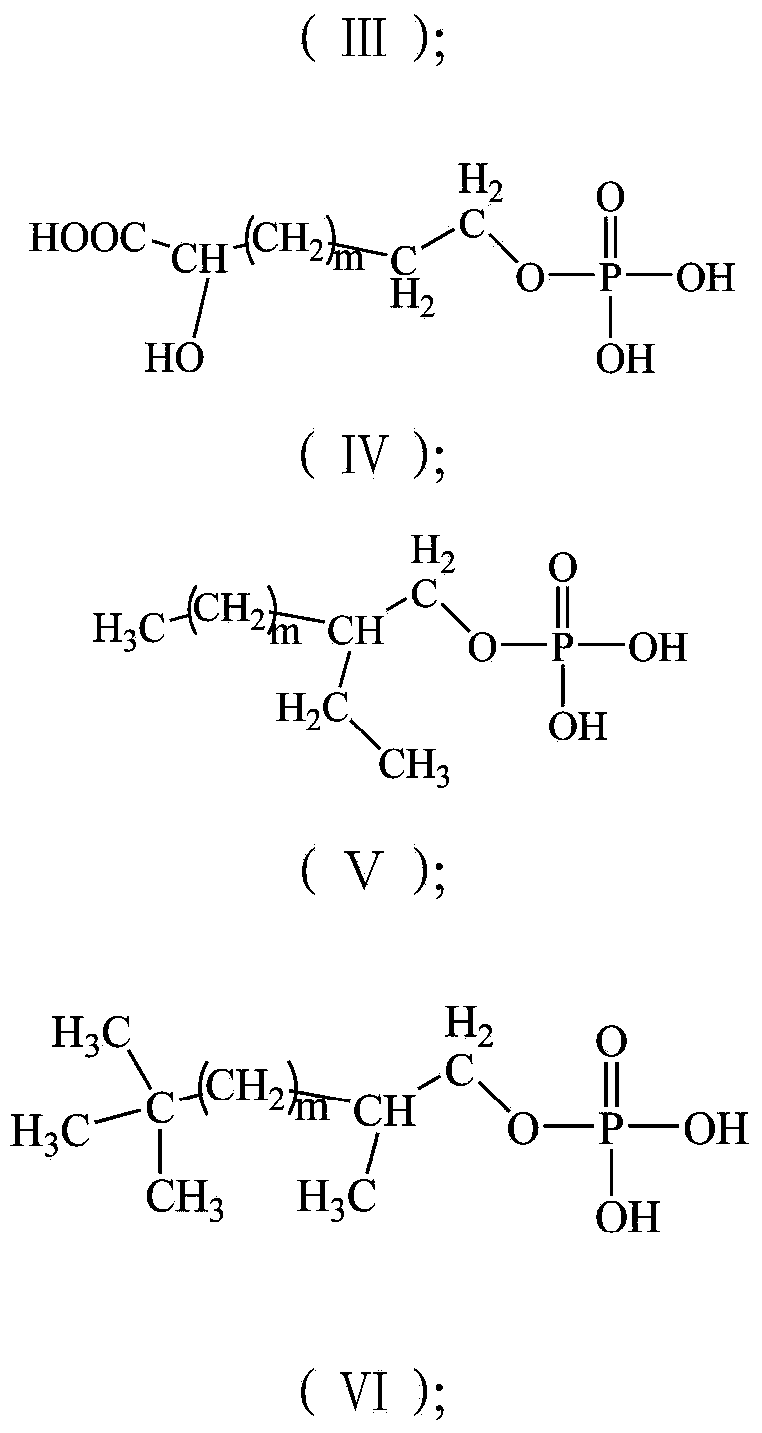

[0059] Mix phosphoric acid and phosphoric acid ester with structural formula (I) in a molar ratio of 0.1:1 to obtain a phosphoric acid-phosphoric acid ester dopant, and then mix it with intrinsic polyaniline and water in a molar ratio of 0.5:1:40. Soak in water for 6 hours, filter, wash with water until the filtrate is neutral, and dry the filter cake in an oven to obtain phosphoric acid-phosphoric acid ester doped polyaniline.

[0060]

[0061] Among them, m is 3.

[0062] Take by weighing 100 grams of epoxy resin E51, 150 grams of xylene, and 150 grams of n-butanol respectively and put them into a sand mill tank, and put into the above-mentioned phosphoric acid-phosphoric acid ester doped polyaniline powder 10 with stirring at a speed of 700 rpm. gram, stirred for 0.5 hour, then added 10 grams of dispersant BYK163, 180 grams of aluminum dihydrogen tripolyphosphate, 180 grams of zinc phosphate, and 50 grams of talcum powder under stirring, and stirred at a speed of 1800 rp...

Embodiment 2

[0065] Mix phosphoric acid and phosphoric acid ester with structural formula (II) at a molar ratio of 1:1 to obtain a phosphoric acid-phosphoric acid ester dopant, and then mix it with intrinsic polyaniline and water at a molar ratio of 0.1:1:45. Soak in water for 6 hours, filter, wash with water until the filtrate is neutral, and dry the filter cake in an oven to obtain phosphoric acid-phosphoric acid ester doped polyaniline.

[0066]

[0067] Among them, m is 1.

[0068] Take by weighing 200 grams of epoxy resin E44, 130 grams of xylene, and 120 grams of n-butanol respectively and put them into a sand mill tank, and put them into the above-mentioned phosphoric acid-phosphoric acid ester doped polyaniline powder for 30 minutes under stirring at a speed of 1000 rpm. grams, stirred for 1 hour, then added 10 grams of dispersant BYK163, 10 grams of leveling agent BYK358, 120 grams of aluminum dihydrogen tripolyphosphate, 100 grams of zinc phosphate, 40 grams of talcum powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com