Flame-retardant non-woven fabric and preparation method thereof

A flame retardant non-woven and non-woven technology, applied in separation methods, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of high moisture regain of filter materials, shortened service life, blockage of filter materials, etc. The effect of long life, not easy to block, low moisture absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

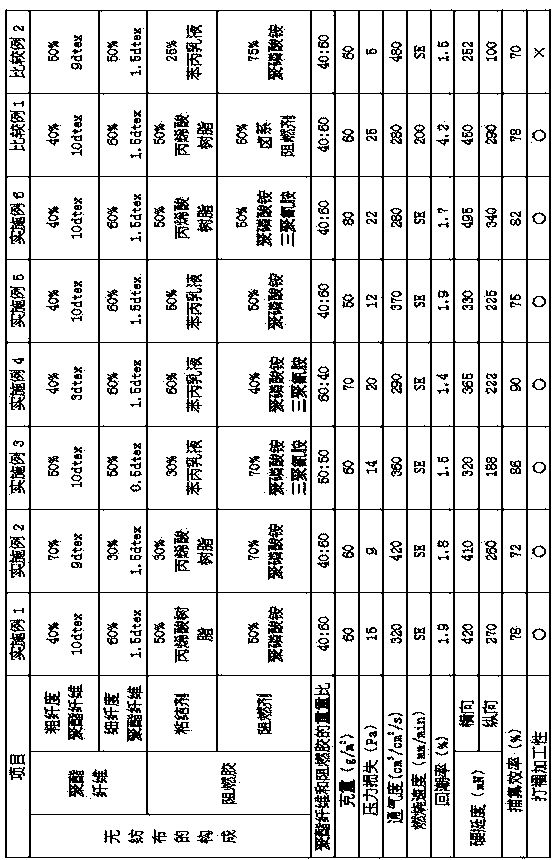

Examples

Embodiment 1

[0039] (1) Preparation of polyester fiber web: 40% by weight of 10dtex thick polyester fiber and 60% by weight of 1.5dtex fine polyester fiber are uniformly mixed in water, and then formed by wet method. Fiber web;

[0040] (2) Preparation of flame retardant glue: mix ammonium polyphosphate flame retardant with a binder whose main component is acrylic resin at a weight ratio of 50:50 to prepare a blend of flame retardant and binder;

[0041] (3) Preparation of non-woven fabric: Coat the flame retardant glue prepared above on the surface of the polyester fiber web, pass through a vacuum suction device, and then enter an oven at 160°C at a speed of 15m / min for drying, reinforcement and molding, and then Trim the edge and roll it into a roll, and finally make a flame-retardant non-woven fabric, which contains 40% by weight of polyester fiber and 60% by weight of flame-retardant glue. The physical properties of the nonwoven fabric are shown in Table 1.

Embodiment 2

[0043] (1) Preparation of polyester fiber web: Use 70% by weight of 9dtex thick polyester fiber and 30% by weight of 1.5dtex thin polyester fiber to uniformly mix in water, and then use wet method to form polyester fiber. Fiber web;

[0044] (2) Preparation of flame retardant glue: mix ammonium polyphosphate flame retardant with a binder whose main component is acrylic resin at a weight ratio of 70:30 to prepare a blend of flame retardant and binder;

[0045] (3) Preparation of non-woven fabric: Coat the flame retardant glue prepared above on the surface of the polyester fiber web, pass through a vacuum suction device, and then enter an oven at 170°C at a speed of 20m / min for drying, reinforcement and molding, and then Trim the edge and roll it into a roll, and finally make a flame-retardant non-woven fabric, which contains 40% by weight of polyester fiber and 60% by weight of flame-retardant glue. The physical properties of the nonwoven fabric of the present invention are sh...

Embodiment 3

[0047] (1) Preparation of polyester fiber web: 50% by weight of 10dtex thick polyester fiber and 50% by weight of 0.5dtex fine polyester fiber are uniformly mixed in water, and then formed by wet method. Fiber web;

[0048] (2) Preparation of flame retardant adhesive: Ammonium polyphosphate melamine flame retardant and binder whose main component is styrene-acrylic emulsion are mixed in a weight ratio of 70:30 to prepare a blend of flame retardant and binder thing;

[0049] (3) Preparation of non-woven fabric: Coat the flame retardant glue prepared above on the surface of the polyester fiber web, pass through a vacuum suction device, and then enter an oven at 180°C at a speed of 25m / min for drying, reinforcement and molding, and then Trim the edge and roll it, and finally make a flame-retardant non-woven fabric, which contains 50% by weight of polyester fiber and 50% by weight of flame-retardant glue. The physical properties of the nonwoven fabric of the present invention ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Ventilation | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com