Inner-support-free double-wall locking mouth steel bushing box cofferdam construction method and cofferdam

A construction method and technology of steel casing, which are applied in basic structure engineering, construction and other directions, can solve the problems of unfavorable steel sheet pile insertion and fixation, long construction and reverse cycle, unfavorable dismantling and reverse use, etc. The effect of many, high rigidity, and repeated use times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

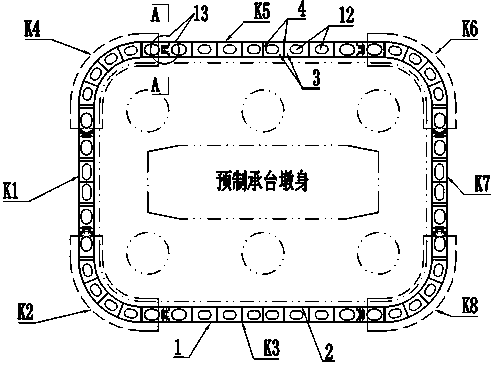

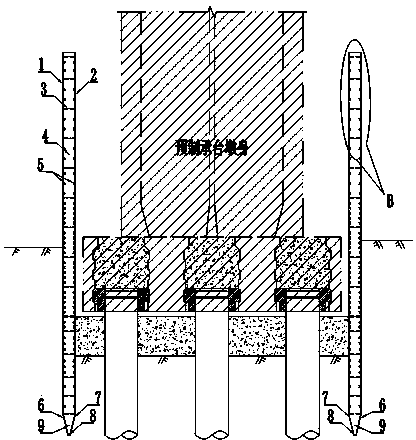

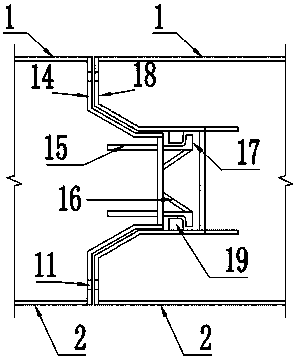

[0030] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0031] A construction method for the cofferdam of double-wall locking steel casing without internal support:

[0032] A. In the factory, the tire frame will be made according to the single block size of the cofferdam of the double-wall locking steel box without internal support. The processing sequence: side plate → blade foot → locking; positioning sequence: outer wall plate 1 → stiffening angle steel 5 → horizontal Partition board 3→upper vertical partition board 4→inner wall board 2→outer baffle board 6→inner baffle board 7→bottom sealing board 8→lower vertical board 9→tenon type lock 13→filling concrete 10. All welds are constructed by segmental jump welding method, every other compartment is welded to a compartment, and then the remaining compartments are fully welded, and then the tenon-type lock 10 is butt-jointed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com