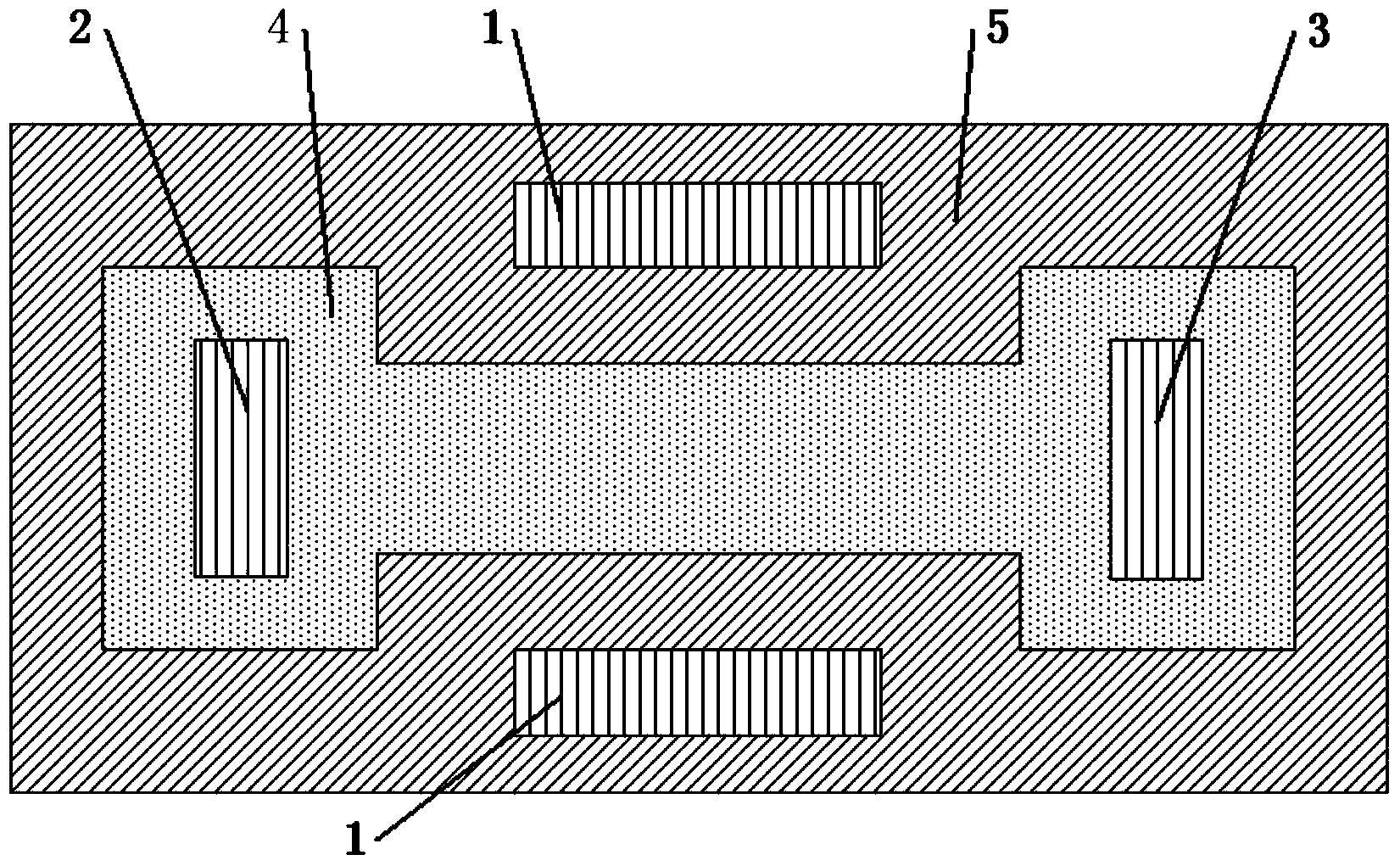

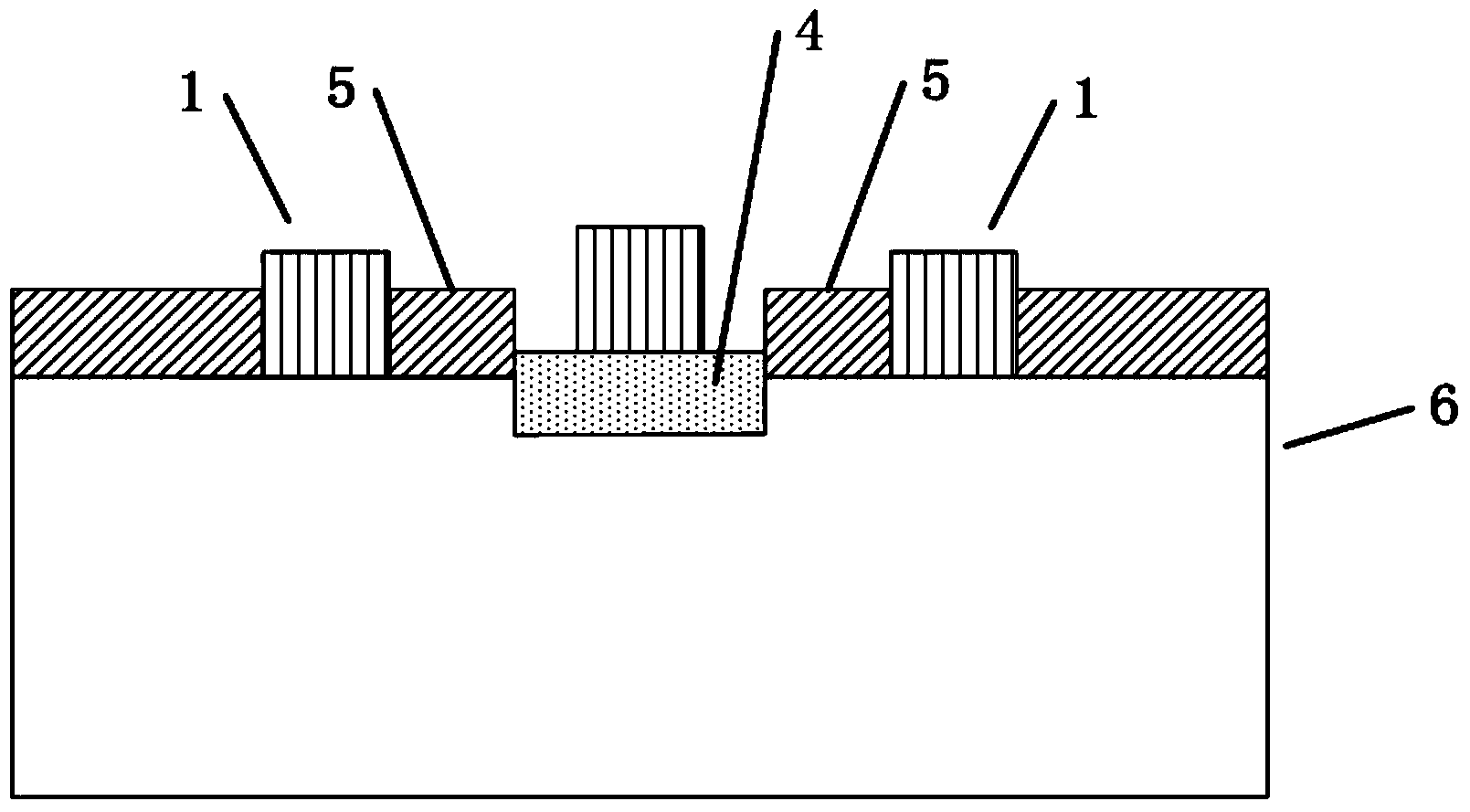

Double-gate graphene transistor with aluminum oxide as gate dielectric and manufacturing method thereof

An aluminum oxide and transistor technology, applied in the field of microelectronics, can solve the problems of growth, can not play an insulating role, affect device performance, etc., and achieve the effects of improving modulation effect, suppressing scattering effect, and simplifying manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

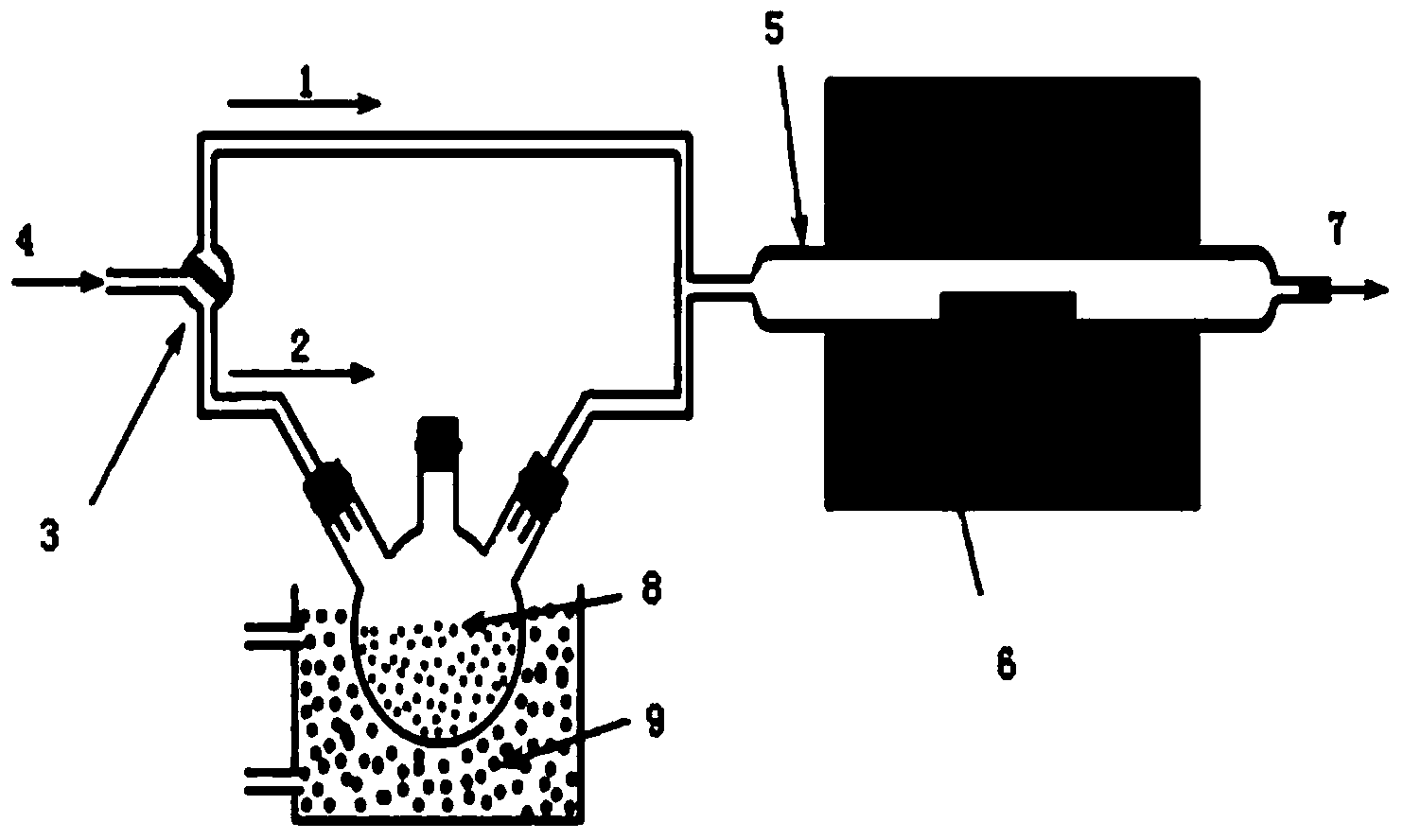

Embodiment 1

[0038] Step 1: Wash the 6H-SiC sample to remove surface contaminants such as Figure 4 (a).

[0039] (1.1) Use NH for 6H-SiC samples 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample;

[0040] (1.2) Use HCl+H on the 6H-SiC sample after removing the surface organic residues 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0041] Step 2: Deposit a layer of Al on the surface of the 6H-SiC sample 2 o 3 ,like Figure 4 (b).

[0042] (2.1) Put the SiC sample into the growth chamber, and flow N into the growth chamber with a flow rate of 10 sccm 2 Perform a 2-minute purge and repeat the cycle 5 times;

[0043] (2.2) Turn on the thermostat, heat the growth chamber to 250°C, and heat the gas path to 40°C for 60 minutes;

[0044] (2.3) Introduce N with a flow rate of 10 sccm into the growth chamber 2 A 2 min purge was perfo...

Embodiment 2

[0072] Step 1: Clean the 4H-SiC sample to remove surface contaminants such as Figure 4 (a).

[0073] Use NH for 4H-SiC samples 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; use HCl+H 2 o 2 The reagent soaked the sample for 10 minutes, took it out and dried it to remove ionic contamination.

[0074] Step 2: Deposit a layer of Al on the surface of the 4H-SiC sample 2 o 3 ,like Figure 4 (b).

[0075] 2a) Put the SiC sample into the growth chamber, and flow 10 sccm of N into the growth chamber 2 Perform a 2-minute purge and repeat the cycle 5 times;

[0076] 2b) Turn on the thermostat, heat the growth chamber to 250°C, and heat the gas path to 40°C for 60 minutes;

[0077] 2c) Flow 10 sccm of N into the growth chamber 2 A 2 min purge was performed and the cycle was repeated 3 times. Thereafter, the flow rate of 15 sccm of N was continuously passed into the growth chamber...

Embodiment 3

[0095] Step A: Use NH on the 4H-SiC substrate substrate 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample; use HCl+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove ionic contaminants such as Figure 4 (a).

[0096] Step B: Deposit a layer of Al on the surface of the 4H-SiC sample 2 o 3 film, such as Figure 4 (b)

[0097] B1) Put the SiC sample into the growth chamber, and flow 10 sccm of N into the growth chamber 2 Perform a 2-minute purge and repeat the cycle 5 times;

[0098] B2) Turn on the thermostat, heat the growth chamber to 250°C, and heat the air circuit to 40°C for 60 minutes;

[0099] B3) Infuse N with a flow rate of 10 sccm into the growth chamber 2 Carry out the purging of 2 minutes, repeat cycle 3 times, thereafter, feed the N that the flow rate is 15 sccm continuously to the growth chamber 2 ;

[0100] B4) Introduce wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com