Modified polypropylene composite pipe for protecting high-voltage cables

A technology for high-voltage cables and composite pipes, which is applied in the field of modified polypropylene composite pipes for high-voltage cable protection. It can solve the problems of low data accuracy, low protection performance, and deep underground pipes, etc., and achieves a wide range of applications and excellent performance. Corrosion resistance and temperature resistance, the effect of improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

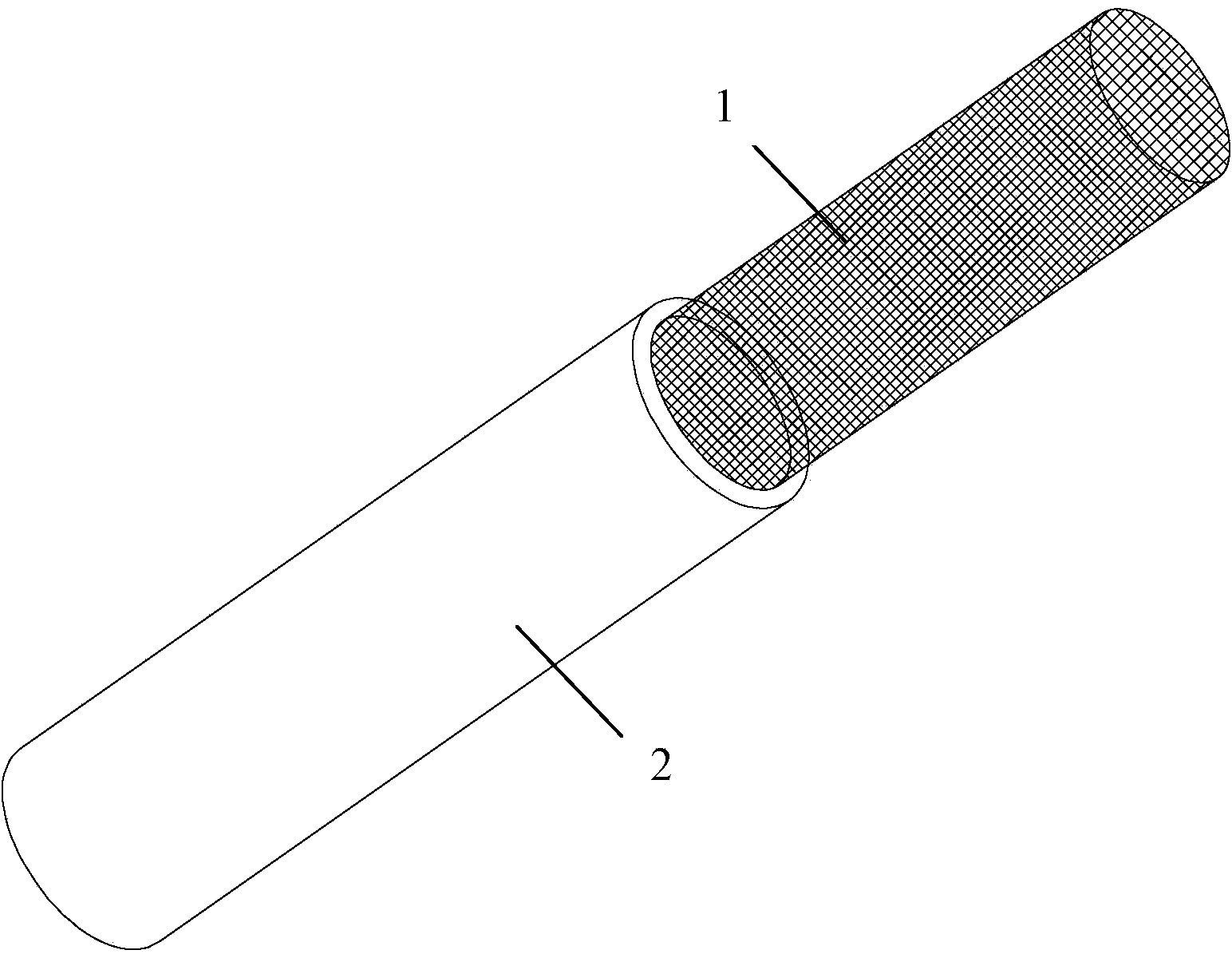

[0019] Such as figure 1 As shown, the modified polypropylene composite pipe for high-voltage cable protection provided in this embodiment is composed of an intermediate layer 1 and an inner and outer layer 2 as a skeleton, wherein the intermediate layer 1 is a metal layer with a diameter of 0.6 mm and arranged along the warp and weft directions. A cylinder made of wire braiding, the distance between adjacent metal wires is 3 mm, and the inner and outer layers 2 are formed by co-extruding modified polypropylene materials on the inner and outer sides of the above-mentioned middle layer 1; Described modified polypropylene material consists of the following components in parts by weight:

[0020] Modified polypropylene (MPP) resin 80 parts

[0021] Polypropylene / styrene-butadiene-styrene block copolymer (PP / SBS) 8 parts

[0022] Polypropylene (PP) color masterbatch 1 part

[0023] Calcium carbonate 2 parts.

[0024] The preparation method is to co-extrude the above-mentioned m...

Embodiment 2

[0026] Such as figure 1 As shown, the modified polypropylene composite pipe for high-voltage cable protection provided in this embodiment is composed of an intermediate layer 1 and an inner and outer layer 2 as a skeleton, wherein the intermediate layer 1 is a metal layer with a diameter of 1.0 mm and arranged along the warp and weft directions. A cylinder made of silk braiding, the distance between adjacent metal wires is 5mm, and the inner and outer layers 2 are made of modified polypropylene material formed on the inner and outer sides of the above-mentioned middle layer 1 by co-extrusion; Described modified polypropylene material consists of the following components in parts by weight:

[0027] Modified polypropylene (MPP) resin 86 parts

[0028] Polypropylene / styrene-butadiene-styrene block copolymer (PP / SBS) 12 parts

[0029] Polypropylene (PP) color masterbatch 2 parts

[0030] 8 parts of calcium carbonate.

[0031] The preparation method is to co-extrude the above-...

Embodiment 3

[0033] Such as figure 1 As shown, the modified polypropylene composite pipe for high-voltage cable protection provided in this embodiment is composed of an intermediate layer 1 and an inner and outer layer 2 as a skeleton, wherein the intermediate layer 1 is made of metal with a diameter of 0.8 mm and arranged along the warp and weft directions. A cylinder made of braided wire, the distance between adjacent metal wires is 4mm, and the inner and outer layers 2 are formed by co-extruding modified polypropylene materials on the inner and outer sides of the above-mentioned middle layer 1; Described modified polypropylene material consists of the following components in parts by weight:

[0034] Modified polypropylene (MPP) resin 83 parts

[0035] Polypropylene / styrene-butadiene-styrene block copolymer (PP / SBS) 10 parts

[0036] Polypropylene (PP) color masterbatch 1.5 parts

[0037] Calcium carbonate 4 parts.

[0038] The preparation method is to co-extrude the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com