Servo driver

A technology of servo drives and inverters, applied in the field of servo drives, can solve problems such as complex systems, high costs, and long development cycles, and achieve the effects of simple systems, low costs, and short development cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

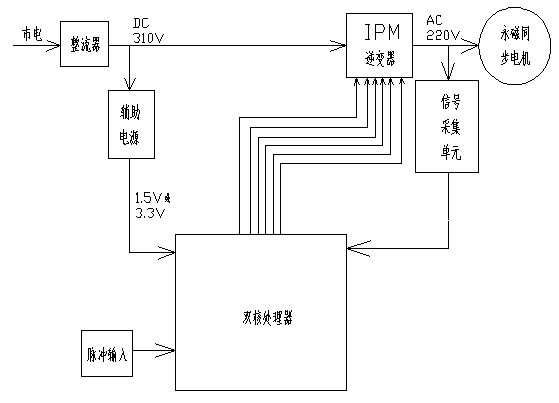

[0019] A kind of servo driver described in embodiment one, rectifier, IPM inverter, signal acquisition unit and dual-core processor are connected in sequence, provide current and voltage signal for dual-core processor; The output terminal of rectifier passes auxiliary power supply and dual-core processor The input terminals of the rectifier and auxiliary power supply are connected to each other. The power supply mode of the rectifier and the auxiliary power supply is mains power, which has low requirements for the working environment. The rectifier converts the mains power into DC with an amplitude of about 310V, and the auxiliary power supply converts the mains power into 15V required by the dual-core processor. , 3.3V and other suitable voltages, the output terminal of the dual-core processor is connected to the control terminal of the IPM inverter, so as to realize the feedback control of the dual-core processor to the IPM inverter. The IPM inverter is continuously turned on...

Embodiment 2

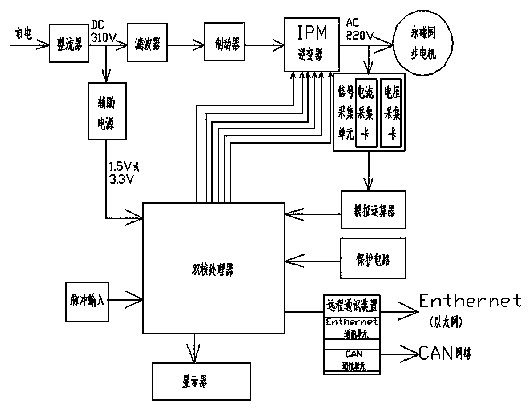

[0022] A kind of servo drive described in embodiment two, rectifier, IPM inverter, signal acquisition unit and dual-core processor are connected sequentially, provide current and voltage signal for dual-core processor; The output terminal of rectifier passes auxiliary power supply and dual-core processor The input terminals of the rectifier and auxiliary power supply are connected to each other. The power supply mode of the rectifier and the auxiliary power supply is mains power, which has low requirements for the working environment. The rectifier converts the mains power into DC with an amplitude of about 310V, and the auxiliary power supply converts the mains power into 15V required by the dual-core processor. , 3.3V and other suitable voltages, the output terminal of the dual-core processor is connected to the control terminal of the IPM inverter, so as to realize the feedback control of the dual-core processor to the IPM inverter. The IPM inverter is continuously turned on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com