IC chip and control circuit of LED directly driven by electronic ballast

An electronic ballast and rectifier circuit technology, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems of power loss, air pollution, excessive heat generation, etc., and achieve low consumption, long service life, and low heat generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

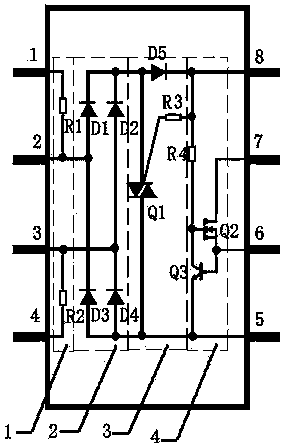

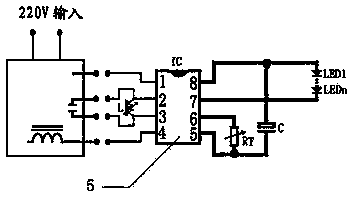

[0019] An electronic ballast directly drives an IC chip of an LED (see attached figure 1 ), is an eight-pin package chip, including four input pins and four output pins, and also includes a protection circuit 1, a rectifier circuit 2, a no-load protection circuit 3 and a constant current source circuit 4, the input terminal of the protection circuit and the input pin The pins are connected, and the output end of the protection circuit is connected with the input end of the rectification circuit. The input end of the rectification circuit 2 is connected to the input pin through the protection circuit 1, the output end of the rectification circuit 2 is connected to the input end of the constant current source circuit 4 through the no-load protection circuit 3, and the output end of the constant current source circuit 4 is connected to the output pin connection.

[0020] The protection circuit 1 includes a resistor R1 and a resistor R2. One end of the resistor R1 is connected to...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, except that the resistor R3 in this embodiment has a resistance value of 330K ohms, and the resistor R4 has a resistance value of 2M ohms. The inductor L in this embodiment is a variable inductor, and the resistor RT is a variable resistor.

[0029] In this embodiment, the user can adjust the output current by adjusting the inductance L and the resistance RT, so that various LED circuits can output matching driving currents.

[0030] This embodiment can solve the problems of large power loss, short life and air pollution of various lighting technologies driven by existing electronic ballasts. This embodiment consumes less, generates less heat, has simple components, is easy to integrate, and is bidirectional Thyristor Q1 works in a semi-conducting state, plays the role of no-load protection, and has a long service life. In this embodiment, the user can freely adjust the output power and constant current output throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com