Preparation method of degraded starch tobacco humectant with mixed hydrolysis degrees

A technology of hydrolyzing starch and degrading starch, which is applied in tobacco, tobacco treatment, application, etc., can solve the problem of unsatisfactory moisturizing effect, achieve the effect of reducing dry mouth, reducing irritation, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] (1) Add 100g starch to 400g deionized water, stir and disperse, and heat to 80℃ for 1h to make the starch fully gelatinized;

[0023] (2) Add hydrochloric acid to the gelatinized starch to make the concentration of hydrochloric acid in the system reach 0.01mol / L;

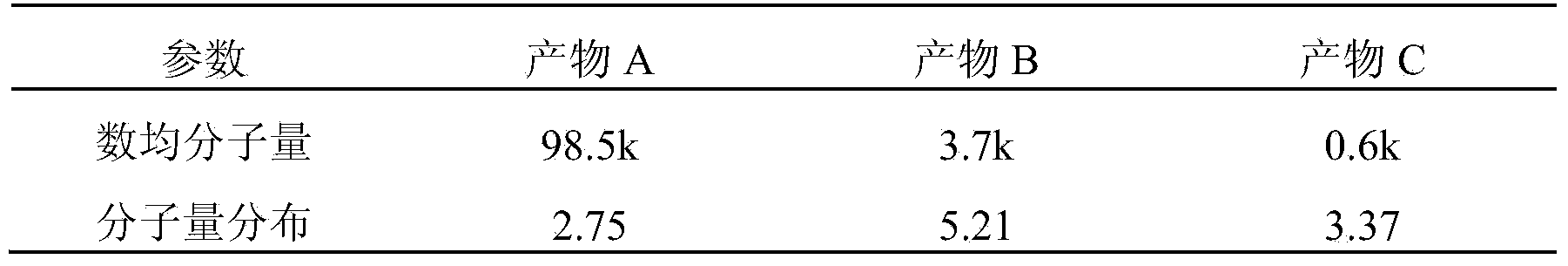

[0024] (3) Heat the gelatinized starch with acid added to 60°C, react for 1 hour, cool down and add alkali to neutralize the excess acid to neutrality to obtain short-time hydrolyzed starch A;

[0025] (4) Heat the gelatinized starch with acid added to 90°C, react for 3 hours, cool down and add alkali to neutralize the excess acid to neutrality to obtain moderately hydrolyzed starch B;

[0026] (5) Heat the gelatinized starch with acid added to 90°C, react for 5 hours, cool down and add alkali to neutralize the excess acid to neutrality to obtain long-term hydrolyzed starch C;

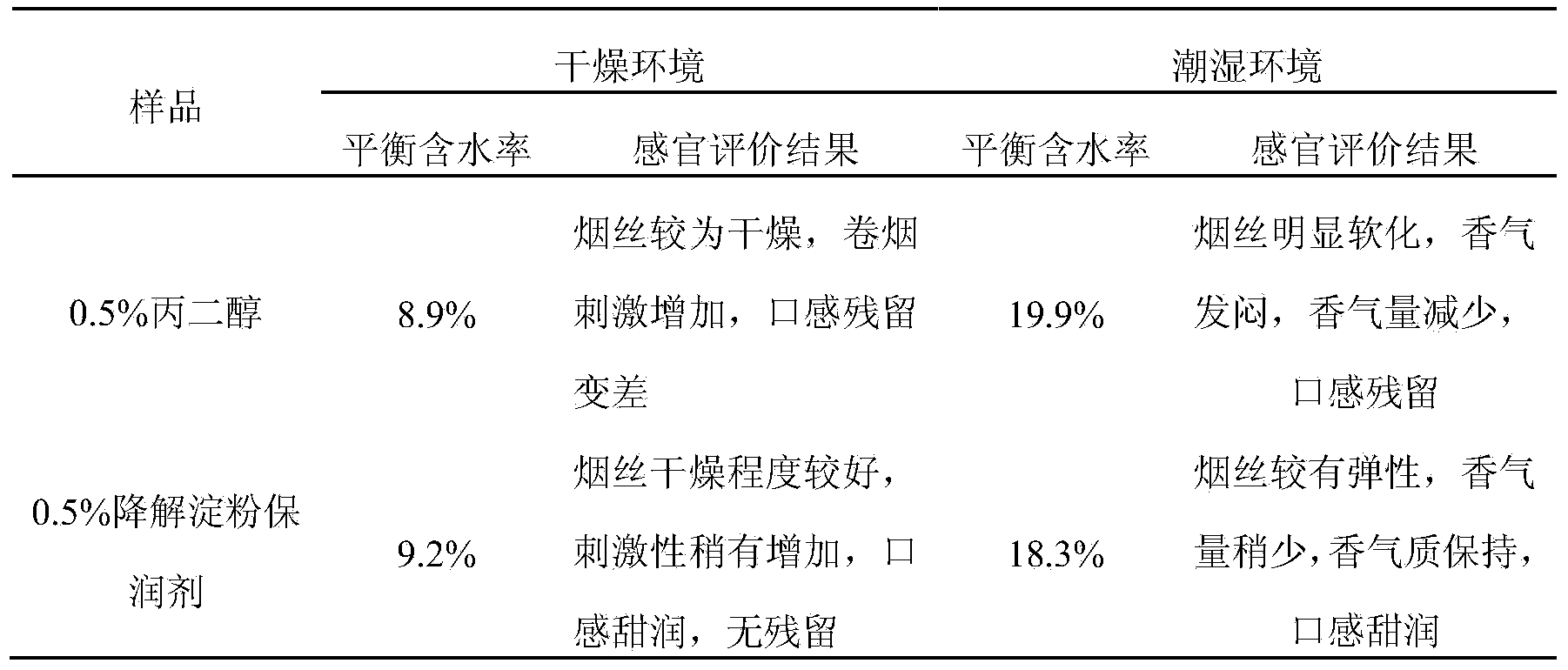

[0027] (6) Mix three kinds of starches with different degrees of hydrolysis to make a moisture retention agent. In terms of weight ratio, star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com