Magnetic core assembly method and system for magnetic card magnetic head

A combined system and combined method technology, applied in the field of magnetic recording, can solve the problems of many manual operations, low work efficiency, and high labor costs, and achieve the effects of ensuring the yield rate, saving labor costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

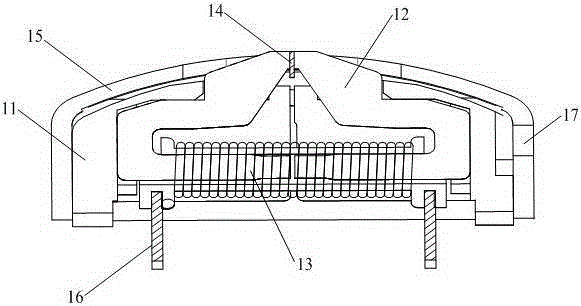

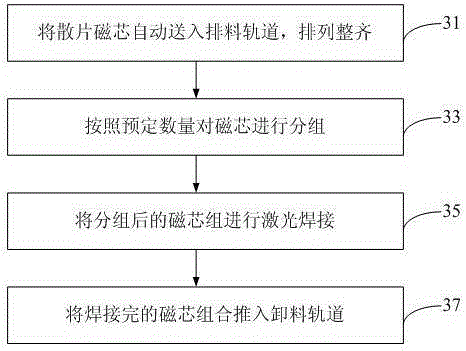

[0028] A magnetic card head generally needs 2~6 magnetic core groups, and each magnetic core group is composed of several loose magnetic cores, and the specific number depends on the shape, thickness and product model of the magnetic core. Scattered magnetic cores are thin parts with small size. It is time-consuming and labor-intensive to combine them manually. However, the assembly process of the magnetic core is the key process in the production process of the magnetic card head. For this reason, the present invention provides a fully automatic magnetic card head magnetic core combination method and combination system. First introduce the magnetic core combination method of the magnetic card magnetic head that the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com