Modified ZSM-5 molecular sieve as well as modifying method and application thereof

A ZSM-5, molecular sieve technology, applied in the field of molecular sieves, can solve the problems of unsatisfactory and unsatisfactory catalytic life and selectivity, and achieve the effects of reducing diffusion resistance, prolonging life and increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

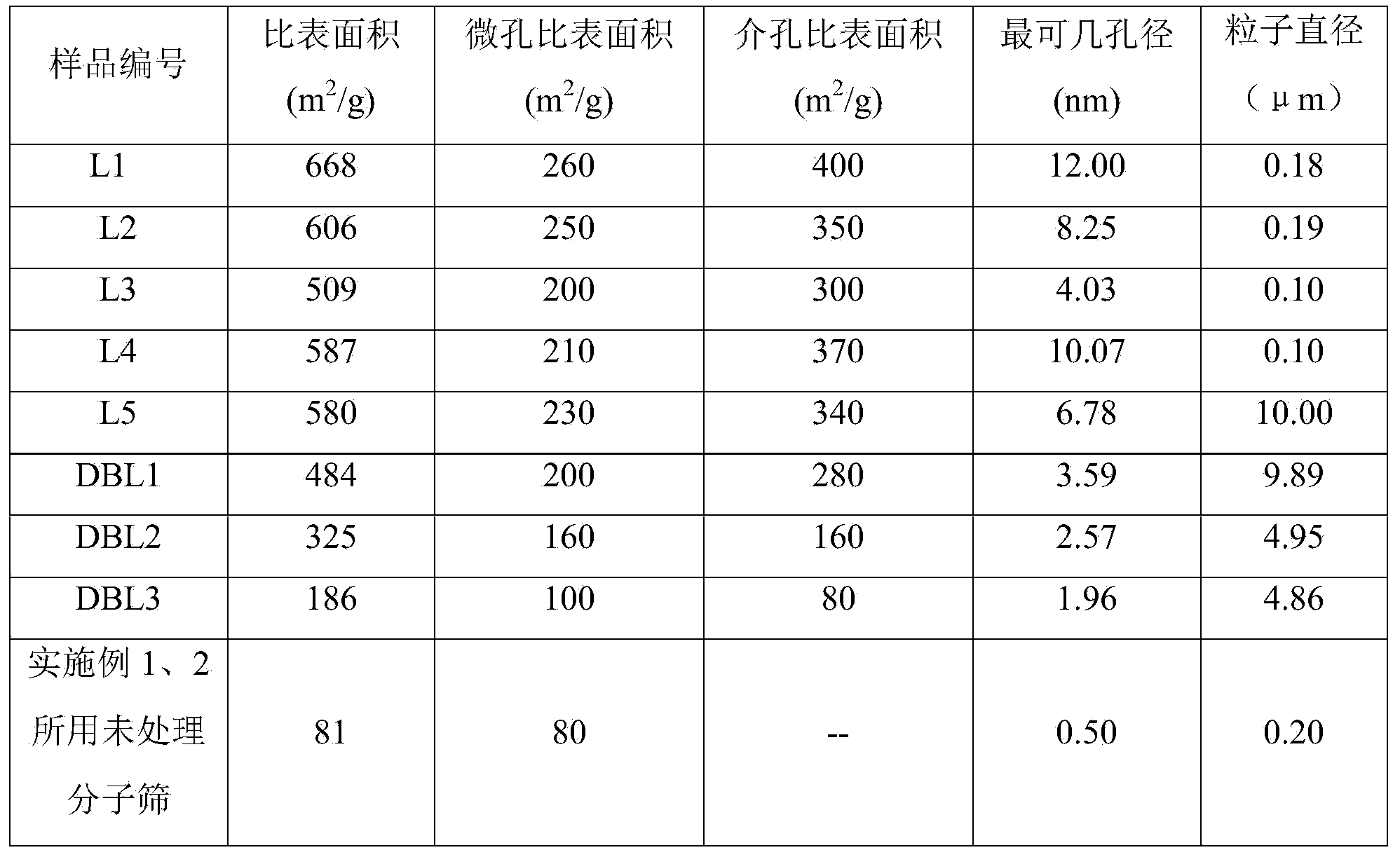

[0038] The molecular sieve used in Example 5 and Comparative Example 1 is the commercial ZSM-5 molecular sieve purchased by Nankai Catalyst Factory. The silicon-aluminum ratio is 20, and the particle size is 10 μm. The most probable pore diameter of the molecular sieve measured by nitrogen adsorption and desorption is 0.1 nm, and the specific surface area 30m 2 / g.

[0039] The molecular sieve used in comparative examples 2 and 3 is the commercial ZSM-5 molecular sieve purchased by Nankai Catalyst Factory. The silicon-aluminum ratio is 100, the particle size is 5 μm, and the most probable pore diameter of the molecular sieve measured by nitrogen adsorption and desorption is 1.0 nm, and the specific surface area is 100 m 2 / g.

Embodiment 1

[0041] (1) Take 20g of purchased commercial ZSM-5 molecular sieve and roast at 500°C for 3 hours;

[0042] (2) Add the roasted ZSM-5 molecular sieve into 400ml of hydrochloric acid solution with a concentration of 2mol / L according to the liquid-solid ratio of 20ml / g, and stir in a water bath at 80°C for 4h;

[0043] (3) Centrifuge the mixture obtained in step (2). The centrifuged solid is stirred and washed 3 times with dilute nitric acid with a concentration of 0.5mol / L in a three-necked flask at a washing temperature of 80°C, and then separated and dried. , Roasting. Among them, the separation process uses centrifugal separation familiar in the industry, the drying process is 12 hours at 120°C, and the roasting process is 550°C for 5 hours.

[0044] (4) Add the product obtained in step (3) into a three-necked flask filled with 400ml of NaOH solution with a concentration of 0.4mol / L, and stir at 80°C for 2h;

[0045] (5) Centrifuge the mixture obtained in step (4). The cent...

Embodiment 2

[0048] (1) Take 10g of purchased commercial ZSM-5 molecular sieve and roast at 600°C for 6 hours;

[0049] (2) Add the roasted ZSM-5 molecular sieve into 500ml of hydrochloric acid solution with a concentration of 4mol / L according to the liquid-solid ratio of 50ml / g, and stir in a water bath at 60°C for 6h;

[0050] (3) The mixture obtained in step (2) is centrifuged, and the centrifuged solid is stirred and washed 3 times with dilute nitric acid with a concentration of 3 mol / L in a three-necked flask at a washing temperature of 60°C, and then separated, dried, Roasting, wherein, the separation process uses filtration separation familiar in the industry, the drying process is 8 hours at 150° C., and the calcination process is 6 hours at 400° C.

[0051] (4) Add the product obtained in step (3) into a three-necked flask filled with 500ml of NaOH solution with a concentration of 0.2mol / L, and stir at 60°C for 4h;

[0052] (5) Centrifuge the mixture obtained in step (4). The cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com