Reactor and method for removing ammonia nitrogen in drinking water by virtue of enhanced filter and method thereof

A reactor, drinking water technology, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc. problems, to achieve the effect of facilitating biofilm growth, convenient operation and management, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

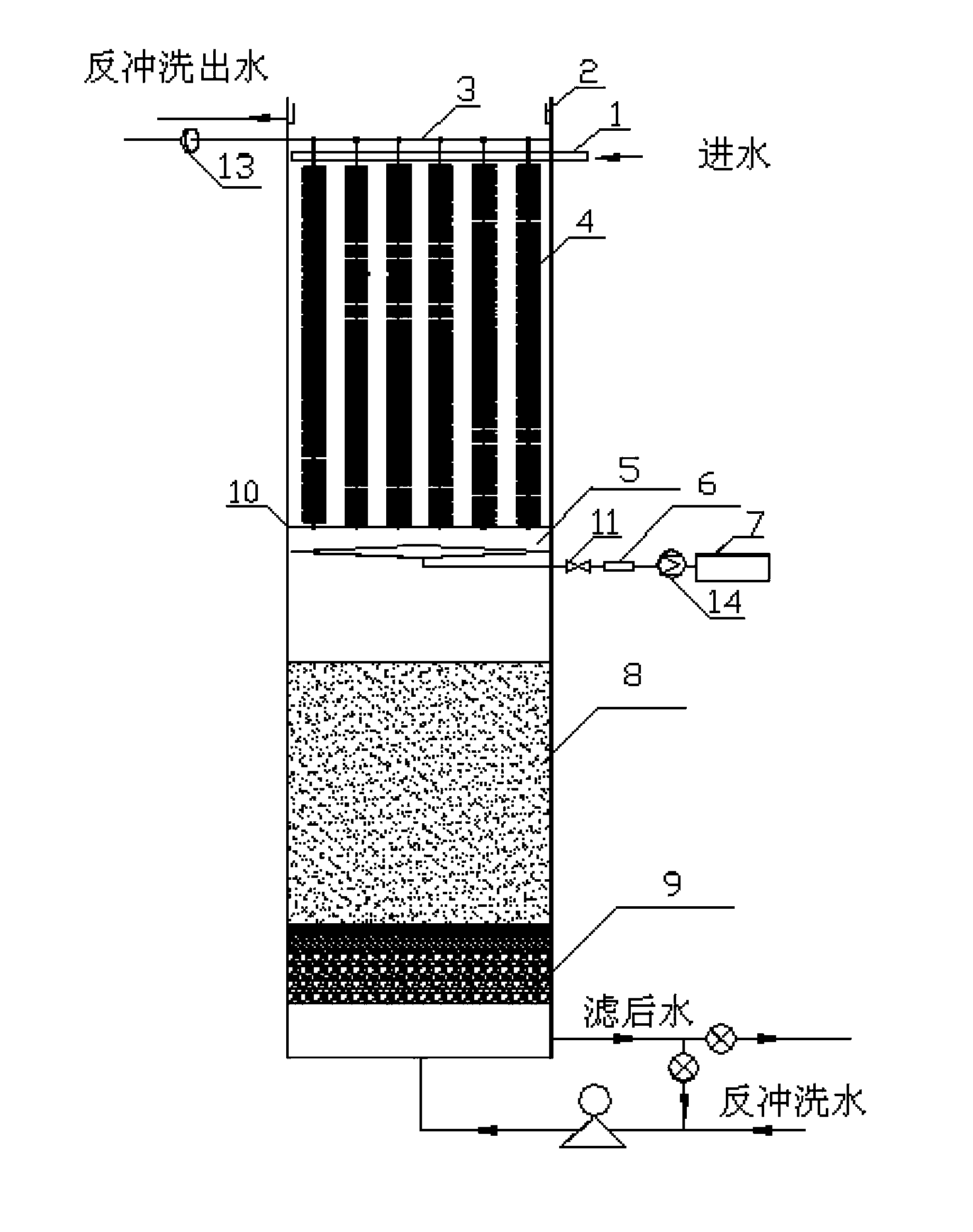

[0043] See figure 1 . 1. It includes the original water inlet area of the sand filter, the original water distribution area of the sand filter, the original filtration area of the sand filter, the original support layer of the sand filter, the original water outlet area of the sand filter, and The backwash system, the additional biological nitrification zone and the additional container of the aeration system constitute a reactor for strengthening the filter tank to remove ammonia nitrogen in drinking water. A water inlet pipe with a plurality of holes is arranged at the original water inlet area of the sand filter tank on the upper part of the container constituting the reactor, so that the water inlet water is evenly distributed in all directions to form a water distribution area 1; A perforated bracket or perforated plate 3 mounted on the bearing 13 is installed on the top of the container located at the upper part of the water inlet pipe.

[0044] The added bio...

Embodiment 2

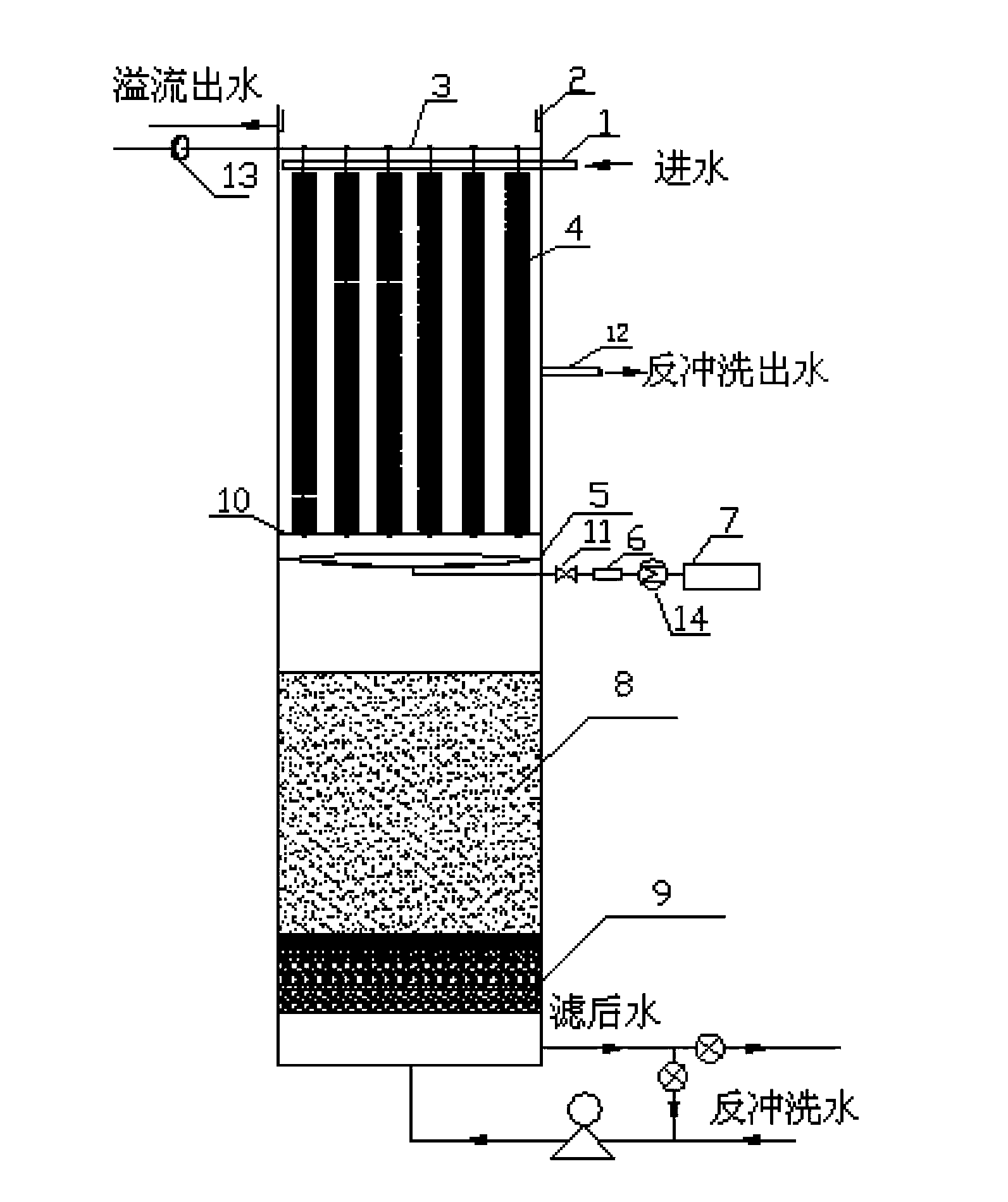

[0057] See figure 2 , the structure of the reactor for strengthening the filter to remove ammonia nitrogen in drinking water is basically the same as that of Example 1, except that the water outlet area above the water inlet pipe of the original water inlet area of the sand filter is installed with overflow weir 2. The water outlet pipeline is changed to a water outlet pipeline installed on the container wall slightly below the middle of the biological nitrification zone where the biological filler is loaded.

[0058] The above-mentioned reactor for removing ammonia nitrogen from drinking water is used to treat the post-sink water of the water plant, and the ammonia nitrogen concentration in the post-sink water of the water plant is 1.0 mg / L. The treatment method is basically the same as in Example 1, except that the additional biological nitrification zone uses a Φ200mm polyamide elastic three-dimensional filler as the carrier for the growth of the microbial film. This bio...

Embodiment 3

[0062] The reactor for removing ammonia nitrogen in drinking water using the enhanced filter tank of Example 2 is used to treat the water after sinking in the water plant, and the ammonia nitrogen concentration in the sinking water in the water plant is 1.5 mg / L. The treatment method is basically the same as in Example 2, except that the additional biological nitrification zone is a combination of Φ150×60mm aldehyde cellulose fiber filler and aldehyde cellulose semi-soft fiber filler as the microbial film growth. The carrier of this kind of biological filler has a large surface area, which is conducive to the growth of microorganisms. The packing density of the biological filler is 44m / m 2 , the height is 1.0 ~ 1.2m. The filter material in the sand filter tank adopts the old quartz sand and anthracite used in the water plant (volume ratio is 1:1), the thickness of the filter material is 1m, and the particle size distribution is 0.8-1.2mm. The supporting layer is paved with l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Packing density | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com