A kind of reaction system and method thereof for synthesizing isobutyl isobutyrate from isobutanol

A technology of isobutyl isobutyrate and reaction system, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of low catalyst activity, achieve high selectivity and high conversion rate of raw materials , the effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

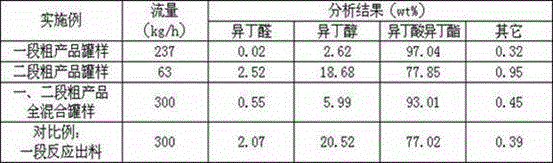

Examples

Embodiment Construction

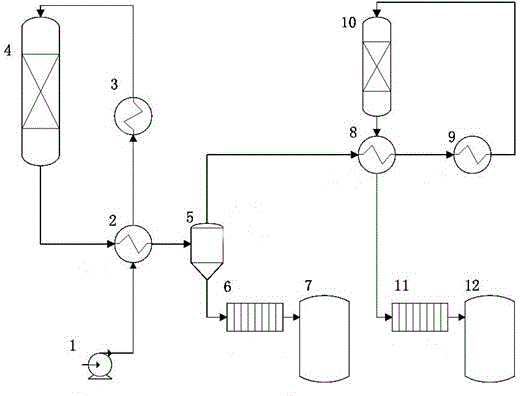

[0010] Such as figure 1 Shown, a kind of reaction system that is used for the synthetic isobutyl isobutyrate of isobutanol comprises one-stage reaction system and two-stage reaction system, and described one-stage reaction system comprises one section feed pump 1, enters with one section feed pump 1 One-stage heat exchanger 2 connected with feed pipeline, one-stage preheater 3 connected with one-stage heat exchanger 2 feed pipe, one-stage fixed-bed reactor 4 connected with one-stage preheater 3 pipe, gas-liquid separator 5, one-stage Cooler 6 and one section of crude product tank 7, the first section of fixed bed reactor 4 discharge pipelines are connected to one section of heat exchanger 2, the one section of heat exchanger 2 discharge pipelines are connected to gas-liquid separator 5, and gas-liquid separator 5 The liquid outlet pipeline at the bottom is connected to a cooler 6, and the cooler 6 is connected to a crude product tank 7; The second-stage preheater 9 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com