Quantitative feeding and discharging mesh biogas production device

A production device and grid-like technology, applied in gas production bioreactors, methods for supporting/fixing microorganisms, biochemical instruments, etc., can solve the problems of unstable fermentation temperature, easy formation of dead angles, easy formation of short circuits, etc., and achieve fermentation concentration. Basic balance, ensure sufficient contact, and avoid the effect of excessive stacking pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

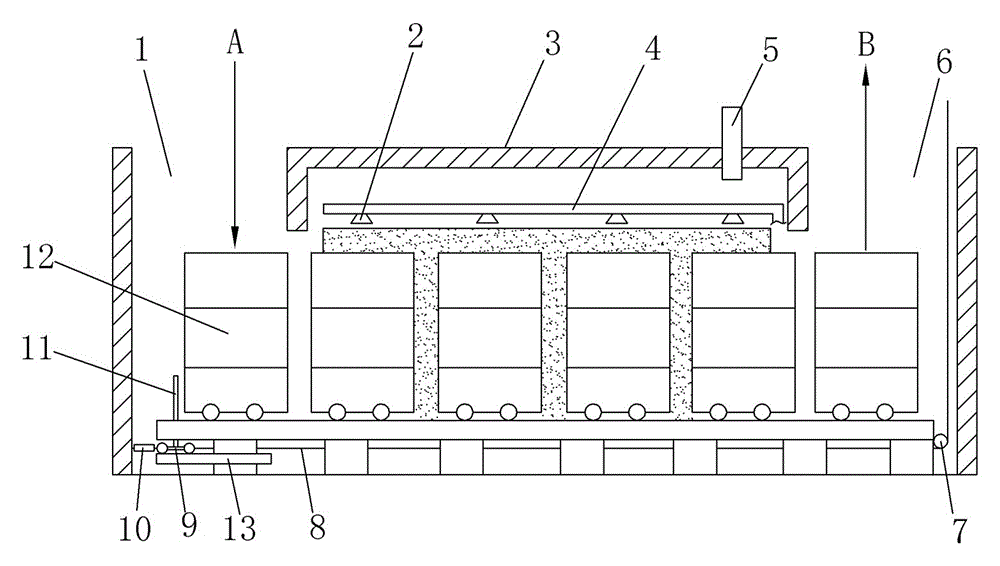

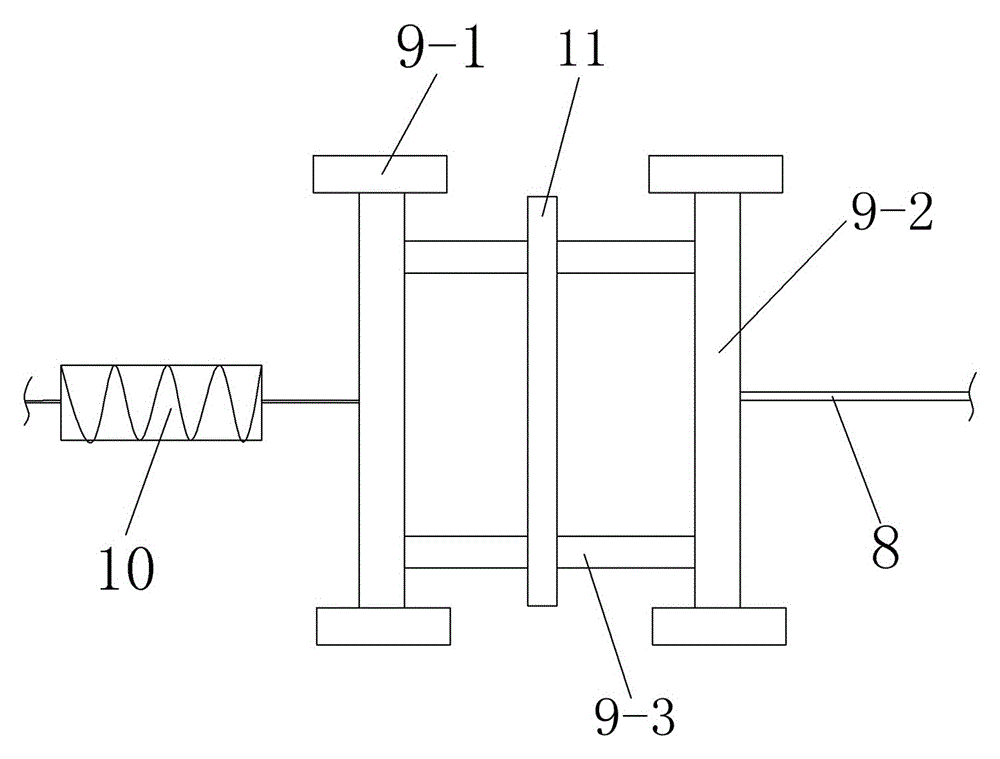

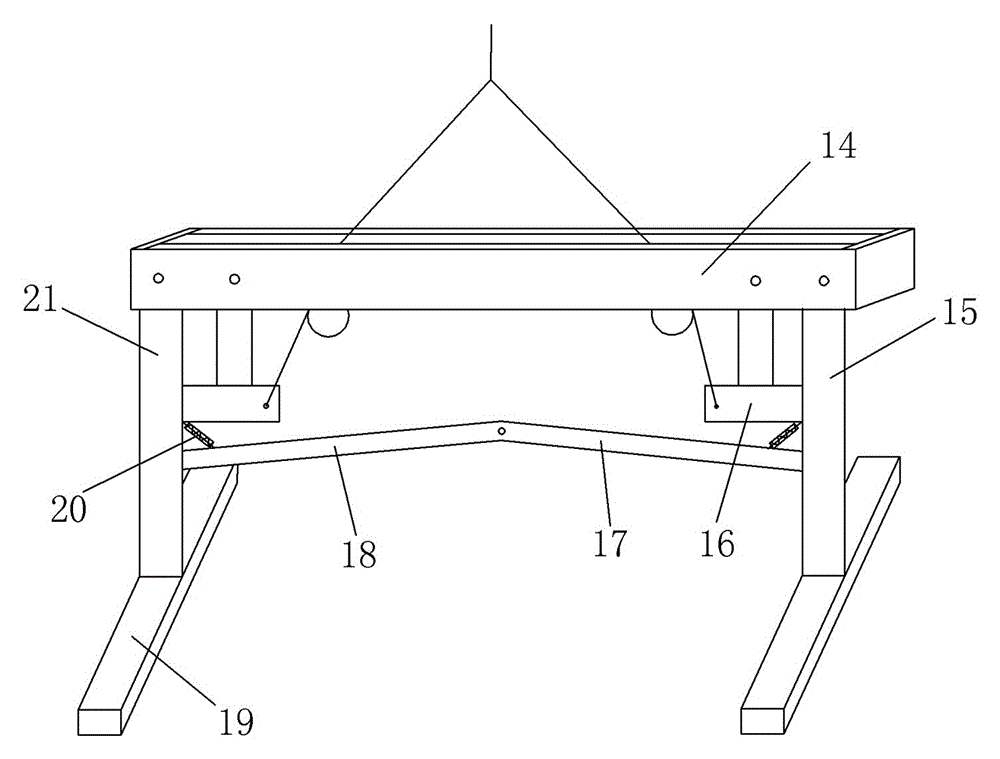

[0025] see Figures 1~3 As shown, the meanings of the symbols in the figure are: 1. Feed inlet, 2. Nozzle, 3. Top cover, 4. Return pipe, 5. Air outlet, 6. Material outlet, 7. Fixed pulley, 8. Wire rope, 9. Thrust car, 10. Spring, 11. Push plate, 12. Material box, 13. Push car guide rail, 14. Main beam, 15. Second movable boom, 16. Connecting plate, 17. Second outer Support plate, 18. the first outer support plate, 19. clamping plate, 20. spring, 21. the first movable boom, 9-1. thrust car roller, 9-2. rotating shaft, 9-3 connecting shaft.

[0026] A quantitative feed-in and out-feed grid type biogas production device, including a biogas tank, a material box, a material box running channel arranged in the biogas tank, a material box lifting device, a material inlet, a material outlet, and a biogas slurry return device arranged in the biogas tank , the fermentation space is set between the feed port and the discharge port in the biogas tank, the top of the biogas tank is sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com