Low-brittleness 700MPa-level automobile beam steel and manufacturing method thereof

A technology of automobile frame and low brittleness, which is applied in the field of metallurgy, can solve the problems of low steel strength and failure to meet the requirements of environmental protection regulations, and achieve the effects of good formability, good low-temperature toughness, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

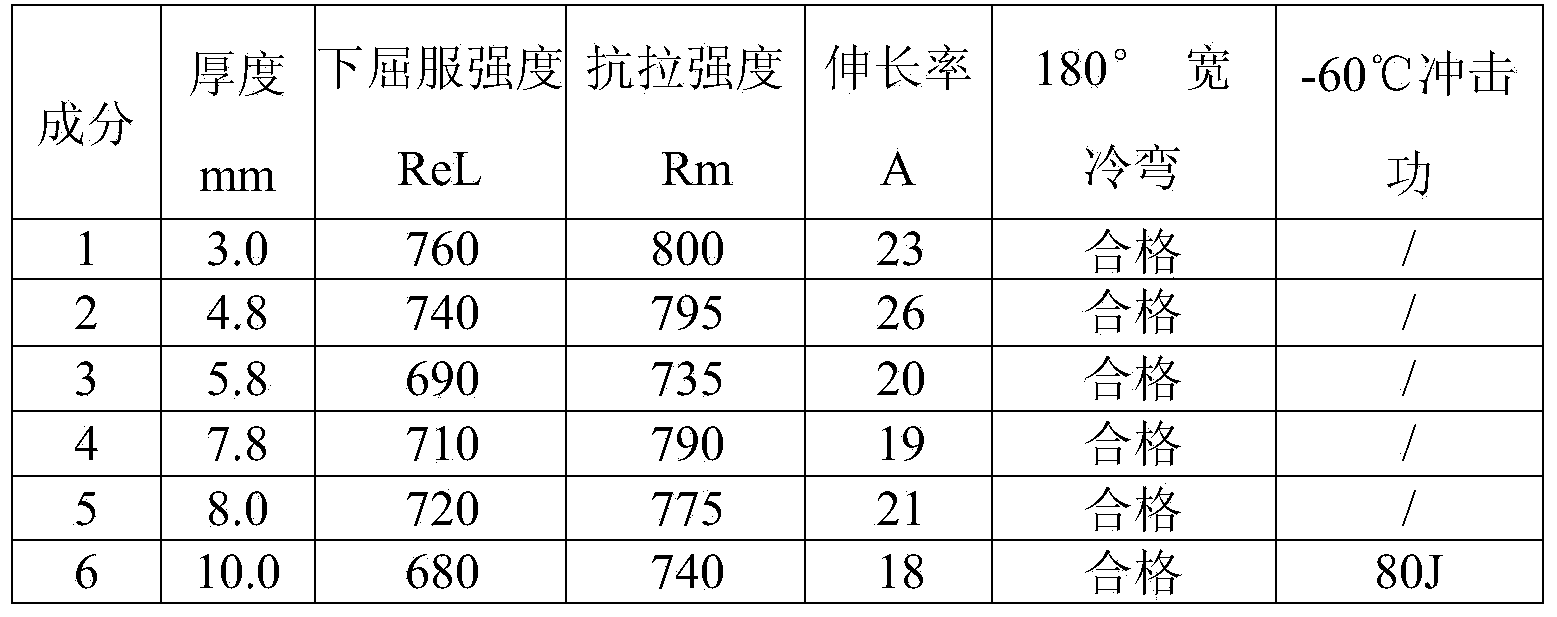

[0049] The low-brittleness 700MPa grade hot-rolled steel for automobile frame was prepared according to the specific chemical composition shown in Table 1. The preparation process is as follows:

[0050] Top-bottom compound blowing is carried out on 90-ton and 250-ton converters in steelmaking plants, and hot metal desulfurization technology is adopted to make S in hot metal ≤ 0.005%; ferroalloy is added when 1 / 3 of the steel is tapped after the furnace, and 2 / 3 of the steel is tapped After the addition is complete, the alloying sequence is: ferro-aluminium→ferromanganese→ferro-niobium, use the aluminum adding machine to add aluminum wire for final deoxidation, add titanium during vacuum treatment, and fine-tune the composition so that the chemical composition in the steel meets the requirements in Table 1. Requirements, the balance is Fe and unavoidable inclusions; then the molten steel with the composition shown in Table 1 is poured into a slab with a cross-section of 230-25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com