Wrapped steel wire mesh cement mortar plate and concrete combined L-shaped bearing column and manufacturing method thereof

A technology of steel wire mesh cement and cement mortar, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of weak seismic performance and poor durability, and achieve improved compressive bearing capacity, improved integrity and durability, and good durability and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiment:

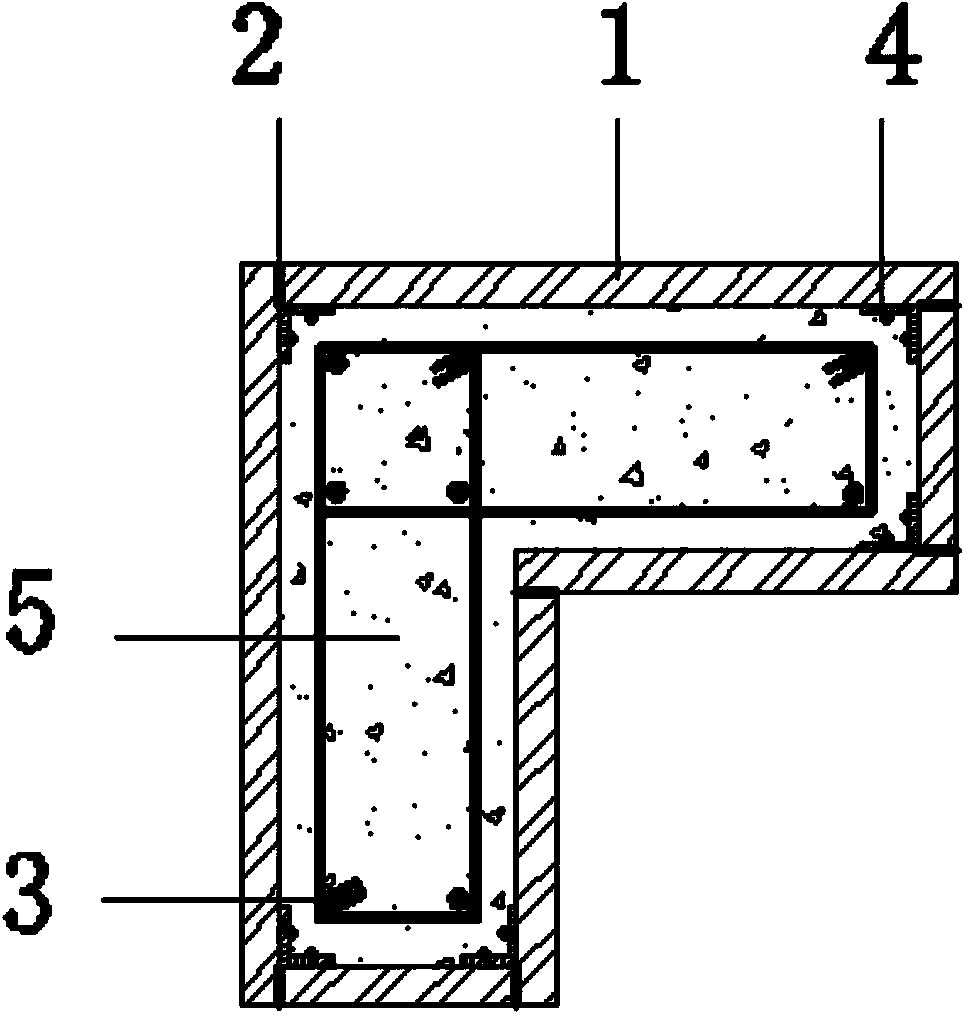

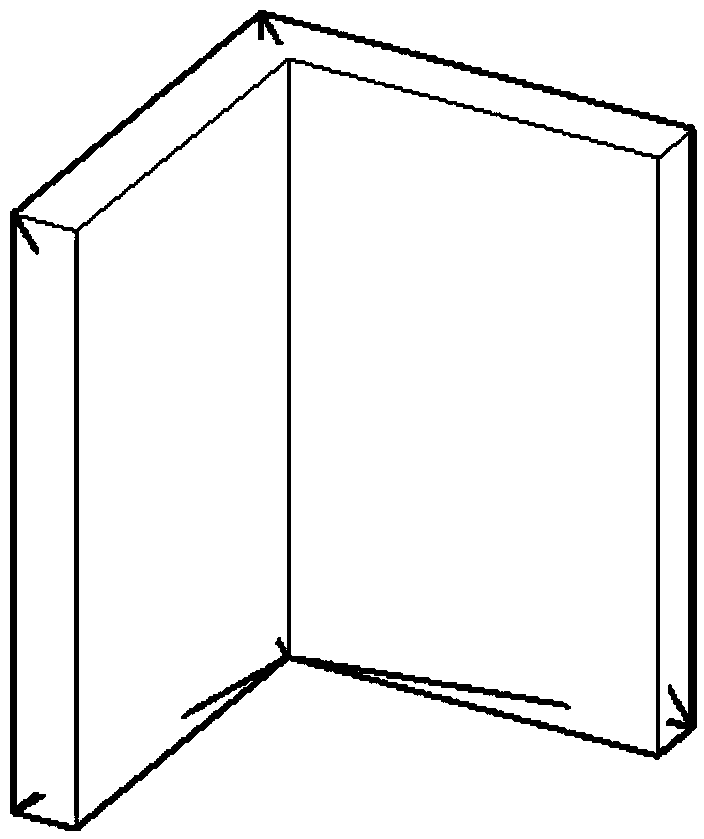

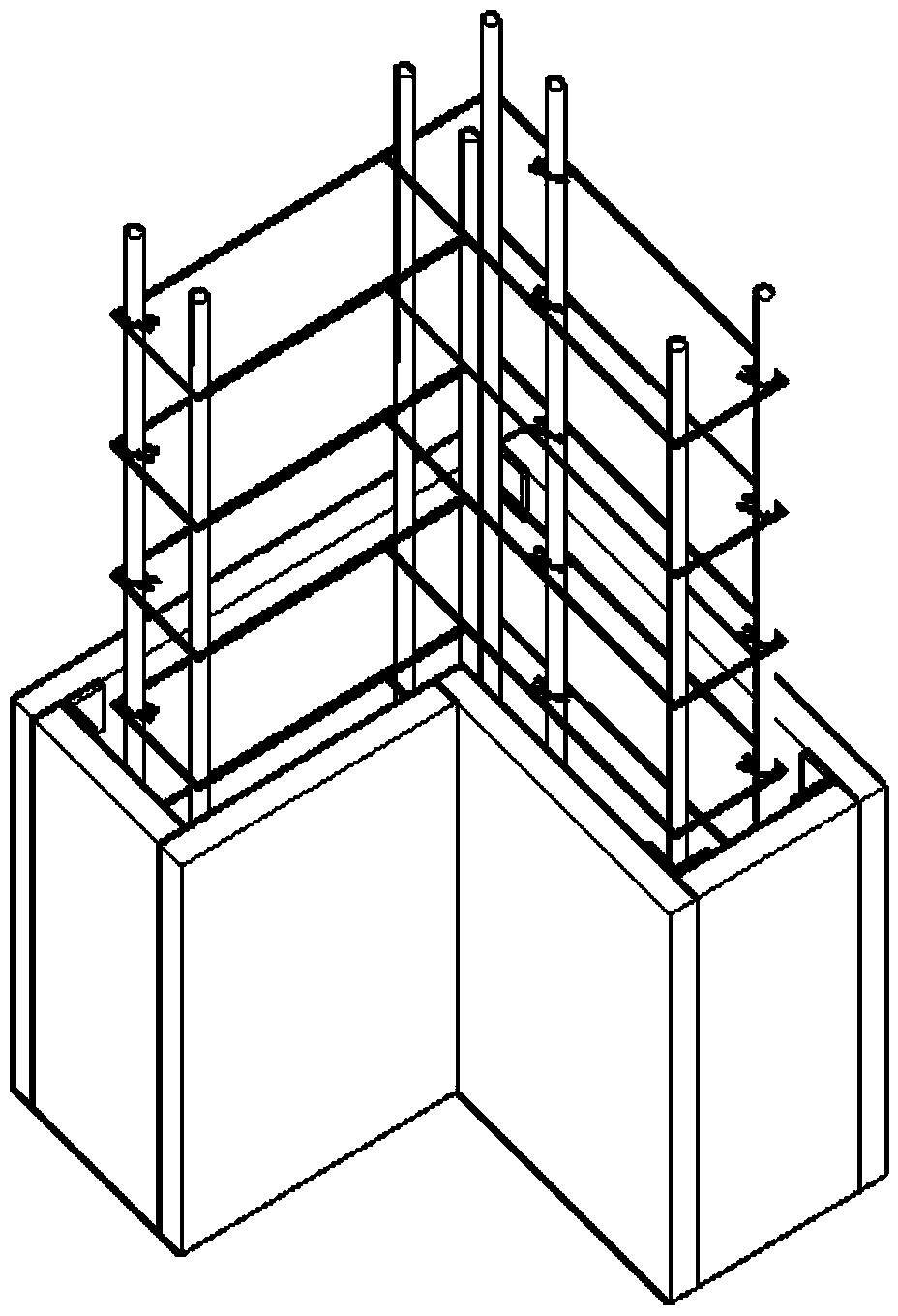

[0028] like Figure 1-3 As shown, the outsourcing steel wire mesh cement mortar board-concrete composite load-bearing L-shaped column of the present invention, the L-shaped column includes a steel wire mesh cement mortar board 1, high polymer mortar 2, hidden column 3, prefabricated connector 4, ordinary concrete or recycled Concrete5. The L-shaped column is made of concealed column reinforcement and integral pouring of concrete, and thus forms three concealed columns 3, including one concealed column 3 at each of the two limbs and one concealed column 3 at the middle corner. The steel wire mesh cement mortar board 1 is wrapped around the L-shaped column as an external enclosure formwork, and the steel wire mesh cement mortar board 1 is connected by a high-polymer mortar 2 and a prefabricated connector 4, and the high-polymer mortar 2 is set on the steel wire cement mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com