Refrigerator and food preservation method thereof

A control method and clothing treatment technology, which is applied in the refrigerator food preservation and refrigerator fields, can solve the problems of increased manufacturing costs and increased refrigerator manufacturing costs, and achieve the effects of improving efficiency, reducing energy consumption, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

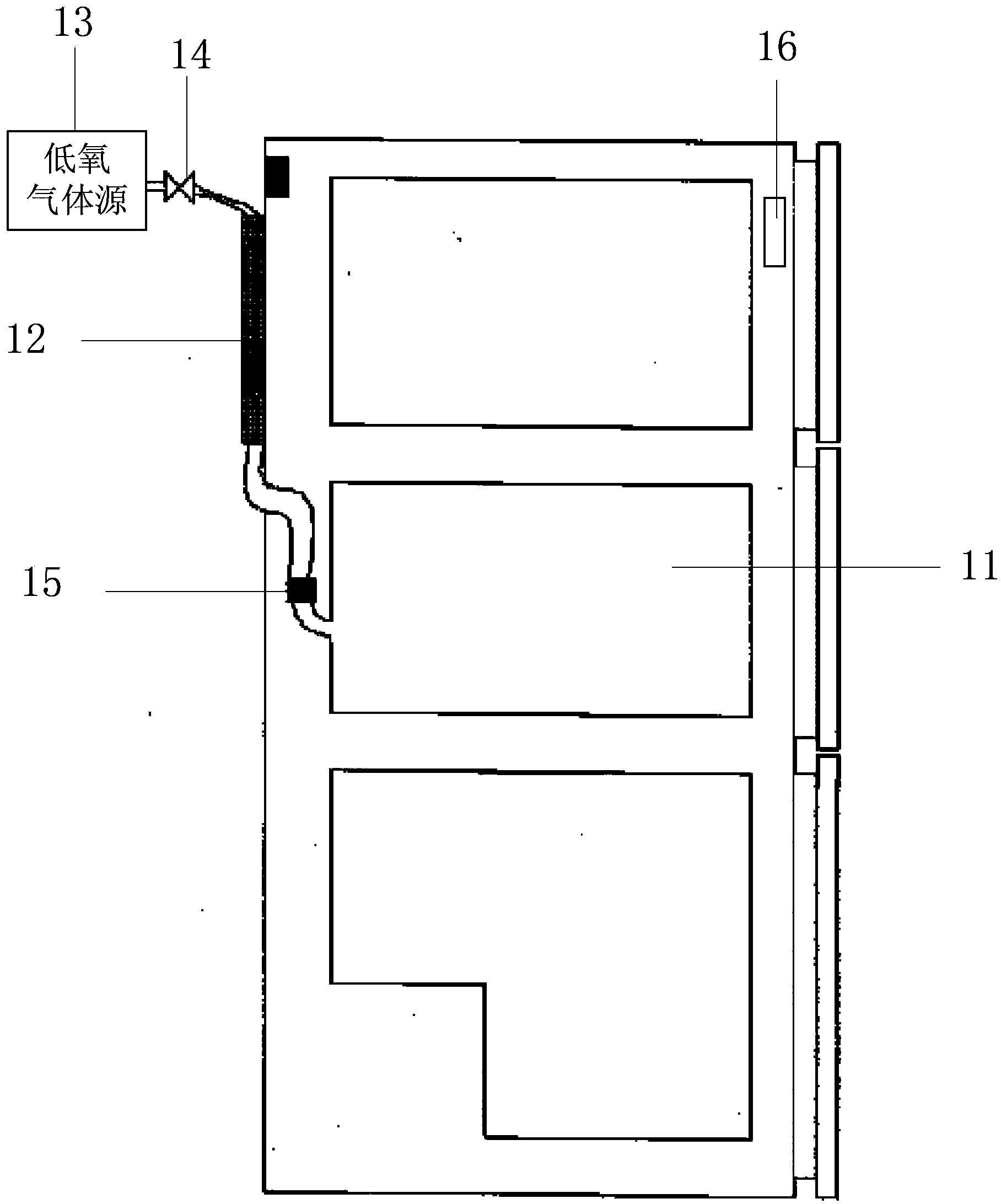

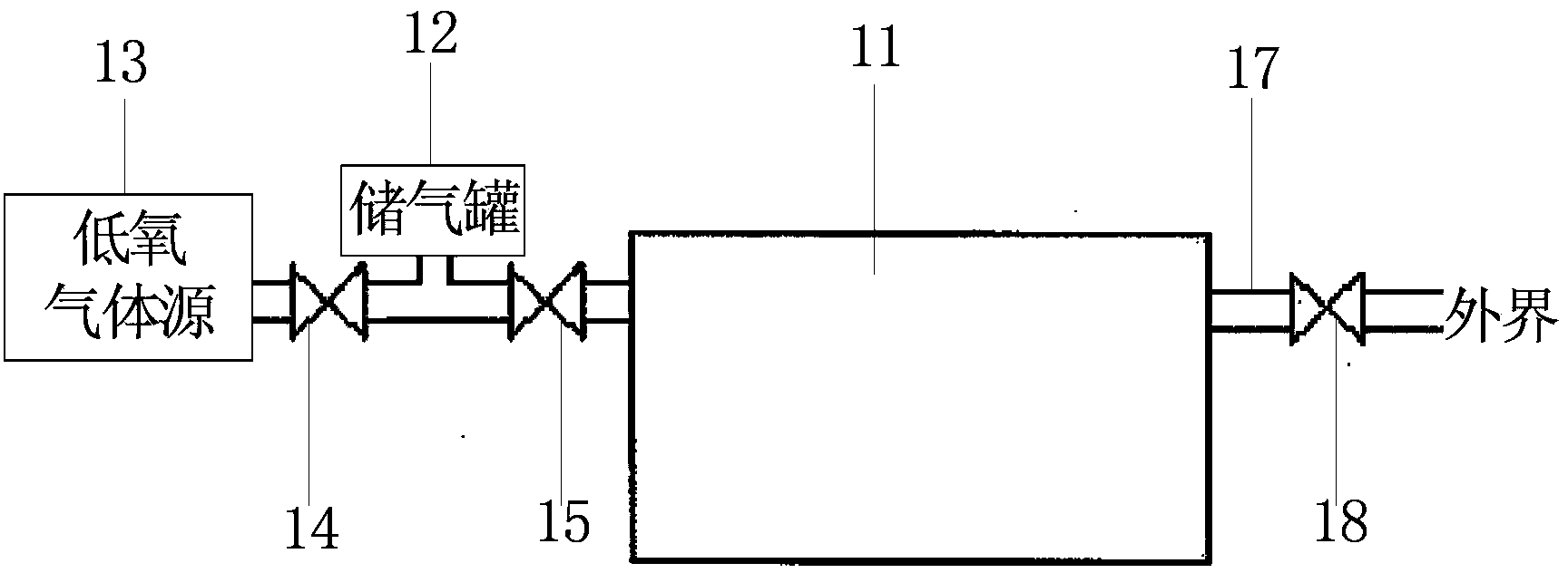

[0059] figure 1 Shown is a schematic structural view of the refrigerator provided in this embodiment, see figure 1 shown, this refrigerator includes:

[0060] storage room 11;

[0061] A gas storage tank 12 suitable for storing compressed gas with low oxygen concentration, and the gas storage tank 12 is used to fill the storage chamber 11 with gas with low oxygen concentration.

[0062] Each component is described in detail below.

[0063] In this embodiment, the storage room 11 is a storage room partially defined by an inner tank (not marked) and partly defined by a door (not marked) corresponding to the inner tank. The inner container can be an inner container of a refrigerating room, or an inner container of a freezing room or a zero-degree fresh-keeping room.

[0064] The gas storage tank 12 is used for storing the low oxygen concentration gas, and the source of the low oxygen concentration gas is the hypoxic gas source 13 . The hypoxic gas source 13 can be set as a p...

Embodiment 2

[0087] The refrigerator provided in the second embodiment and the method for keeping food in the refrigerator are roughly the same as those in the first embodiment. The difference is: if Figure 4 As shown, the storage compartment 11 is formed by a storage unit accommodated in the storage compartment, such as but not limited to a storage box 11'. to combine Figure 5As shown, the storage box 11' is provided with one or more exhaust holes 111' for discharging the gas inside to the storage room 11, preferably, the gas is discharged to the outside through the exhaust channel 17 of the storage room 11. . For storage boxes 11' of different volume sizes, the air vent 111' may have different sizes.

[0088] It can be seen that the storage chamber 11 in the first embodiment has a relatively large volume, so the gas storage tank 12 needs to have a relatively large volume or pressure bearing capacity. The volume of the storage box 11' in the second embodiment is small, so the demand...

Embodiment 3

[0090] The refrigerator provided in the third embodiment and the method for keeping food fresh in the refrigerator are roughly the same as those in the first and second embodiments. The difference is that the air storage tank 12 is placed in the cooled storage space in the refrigerator. The temperature in the cooled storage space is below room temperature, such as but not limited to a cold storage room such as Figure 6 As shown, it can also be other cooled storage spaces in the refrigerator. The advantage of the above scheme is that when the gas storage tank 12 fills the storage chamber 11 with low-oxygen-concentration gas, the low-oxygen-concentration gas has already been cooled, which can reduce energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com