Multi-rotary-wing intelligent inspection robot for overhead line

A technology for patrolling robots and overhead lines, which is applied to overhead lines/cable equipment, rotorcraft, motor vehicles, etc., and can solve problems such as inability to handle, broken strands but not scattered strands, and video imaging that can only be performed at a relatively long distance. Achieve the effect of reducing labor intensity and labor cost and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

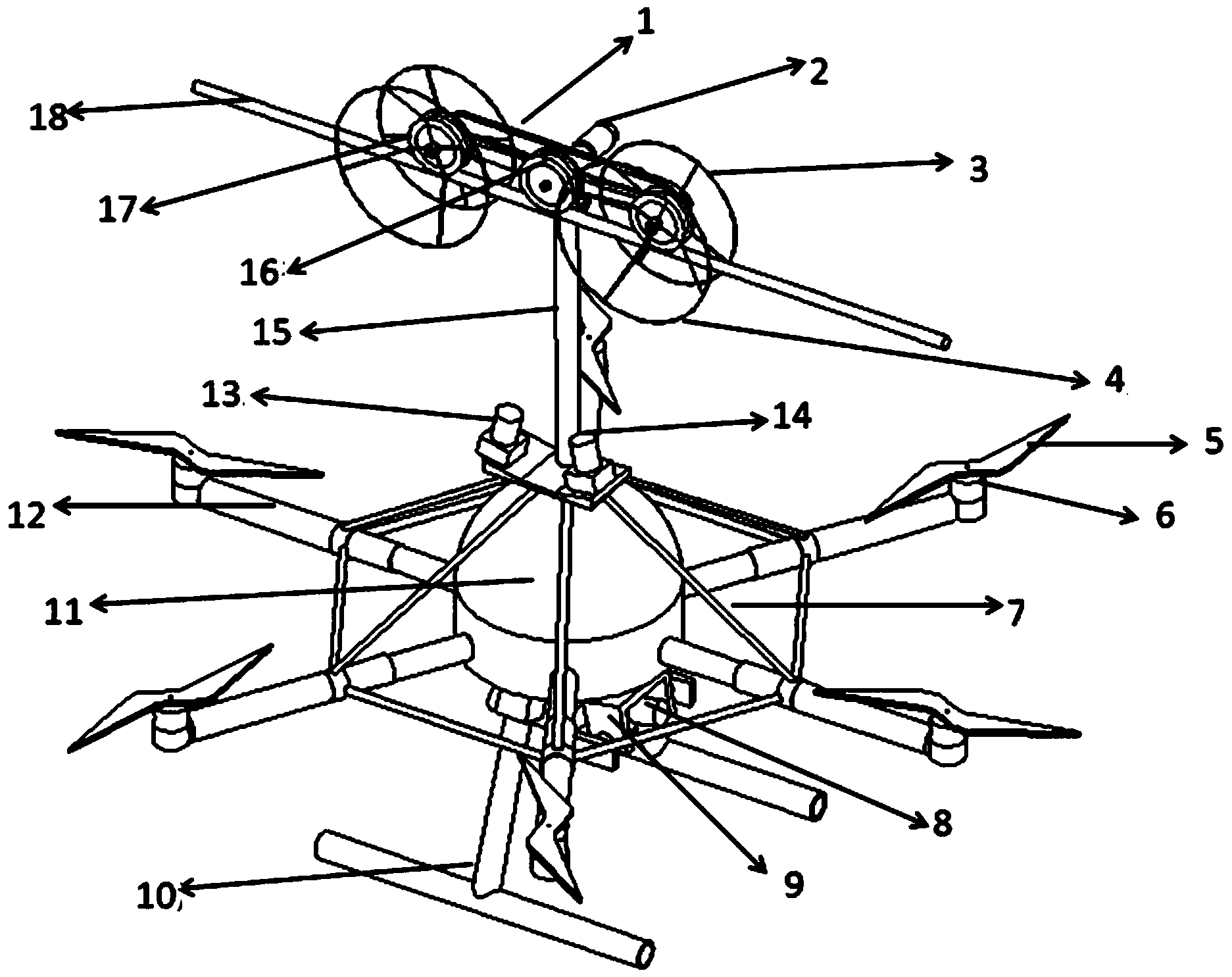

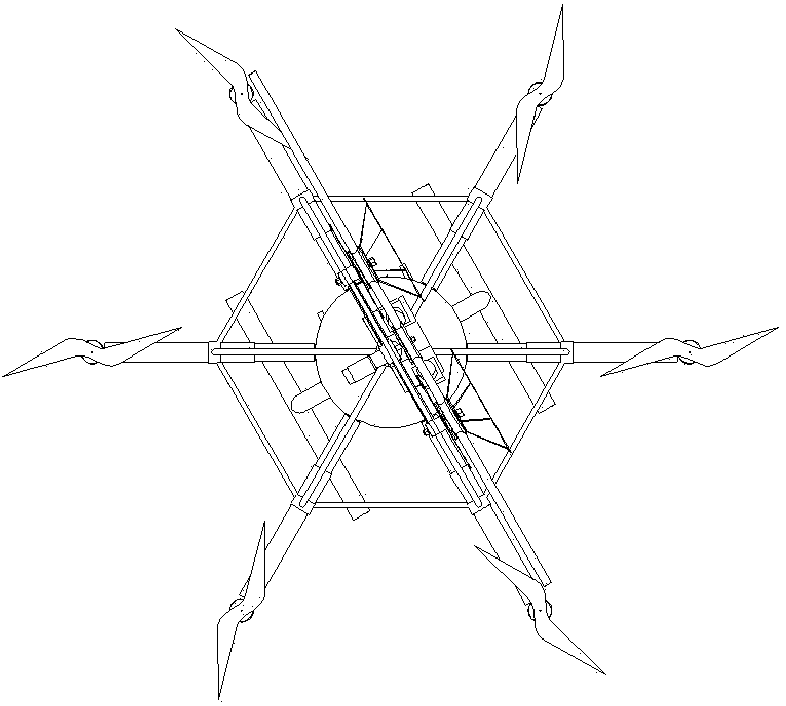

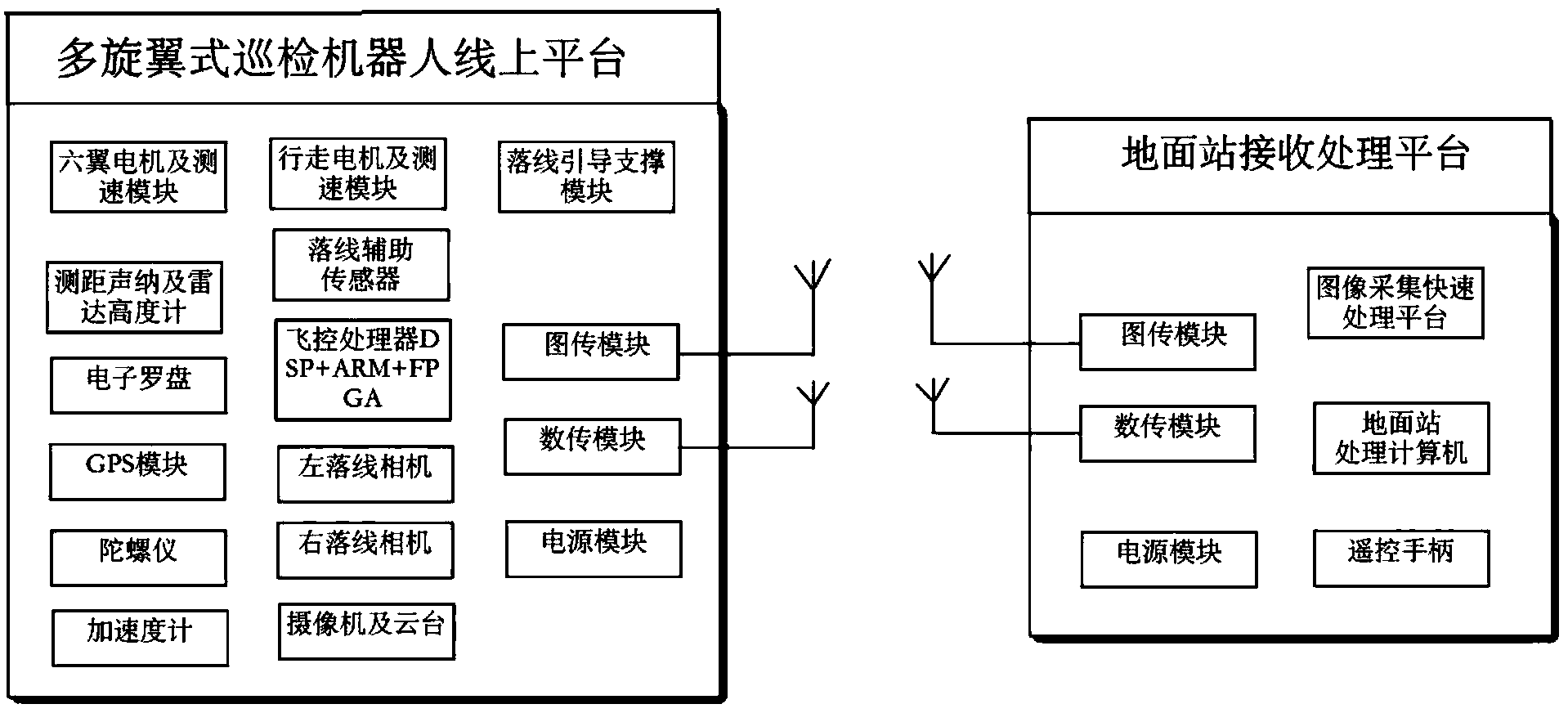

[0032] Such as figure 1 , figure 2 As shown, it includes online walking module, autonomous landing module, multi-rotor flight system module, online platform and ground station receiving and processing platform.

[0033] The online walking module includes: a traveling frame 1, a traveling driving motor 2, an inner guide ring 3, an outer guide ring 4, a traveling driving wheel 16, a traveling supporting wheel 17, and the like.

[0034] The traveling driving motor is connected with the traveling driving wheel through a key, and the driving motor flange is fastened to the middle part of the traveling vehicle frame. The two walking support wheels are connected to the wheel shaft through bearings, and are screwed to the walking frame. Among them, the inner guide ring and the outer guide ring are fixed on both ends of the walking support wheel, which are mainly used for guiding when the line is dropped, so that the transmission line can smoothly fall into the support wheel groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com