Method for preparing Nd: YAG transparent ceramic by using magnesium silicate as sintering aid

A technology of sintering aids and transparent ceramics, applied in the field of transparent ceramics preparation, can solve the problems of grain growth and irregularity, and achieve the effect of improving transparency and inhibiting abnormal grain growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

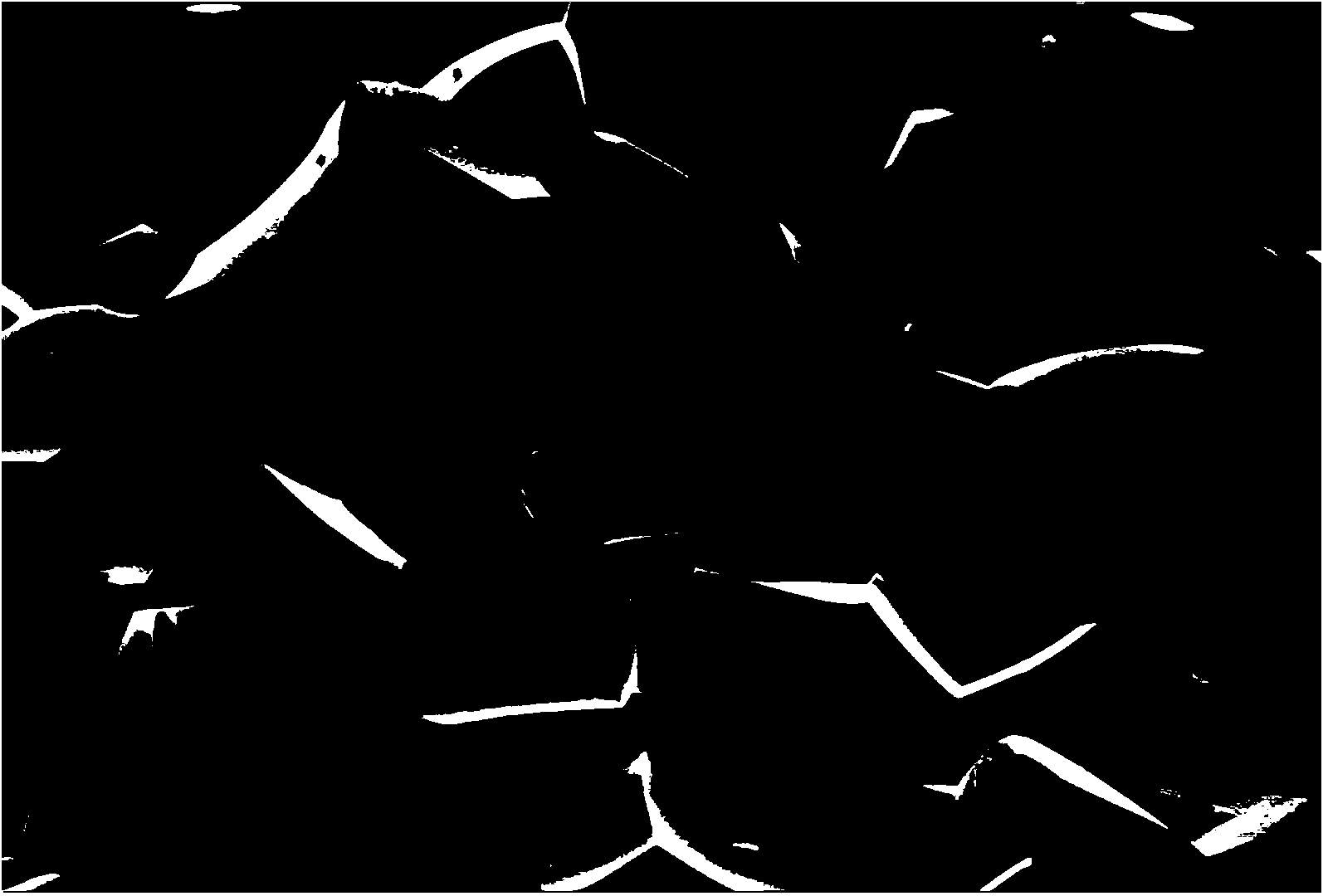

[0026] Weigh 31.68g of Y 2 O 3 , 24.08gAl 2 O 3 , 0.476gNd 2 O 3 , 0.15g of magnesium silicate mass. Add 110g of absolute ethanol, and 300g of alumina grinding balls, mill at 160r / min for 16h, dry and sieve the powder after ball milling, then dry press at 10MPa to form, and then cold isostatically press at 200MPa. The ceramic green body was sintered in vacuum at 1750°C for 10h. The SEM image of the cross-section of the prepared Nd:YAG ceramics is shown in Fig. figure 1 shown.

Embodiment 2

[0028] Weigh 62.74g of Y 2 O 3 , 48.16gAl 2 O 3 , 1.904gNd 2 O 3 , 0.24g of magnesium silicate mass. Add 200g of anhydrous ethanol, and 400g of alumina grinding balls, ball mill at 160r / min for 16h, dry and sieve the powder after ball milling, then dry press at 10MPa to form, and then cold isostatically press at 200MPa. The ceramic green body was sintered in vacuum at 1780°C for 10h. The SEM images of the prepared Nd:YAG ceramics after surface polishing and hot etching are as follows figure 2 shown.

Embodiment 3

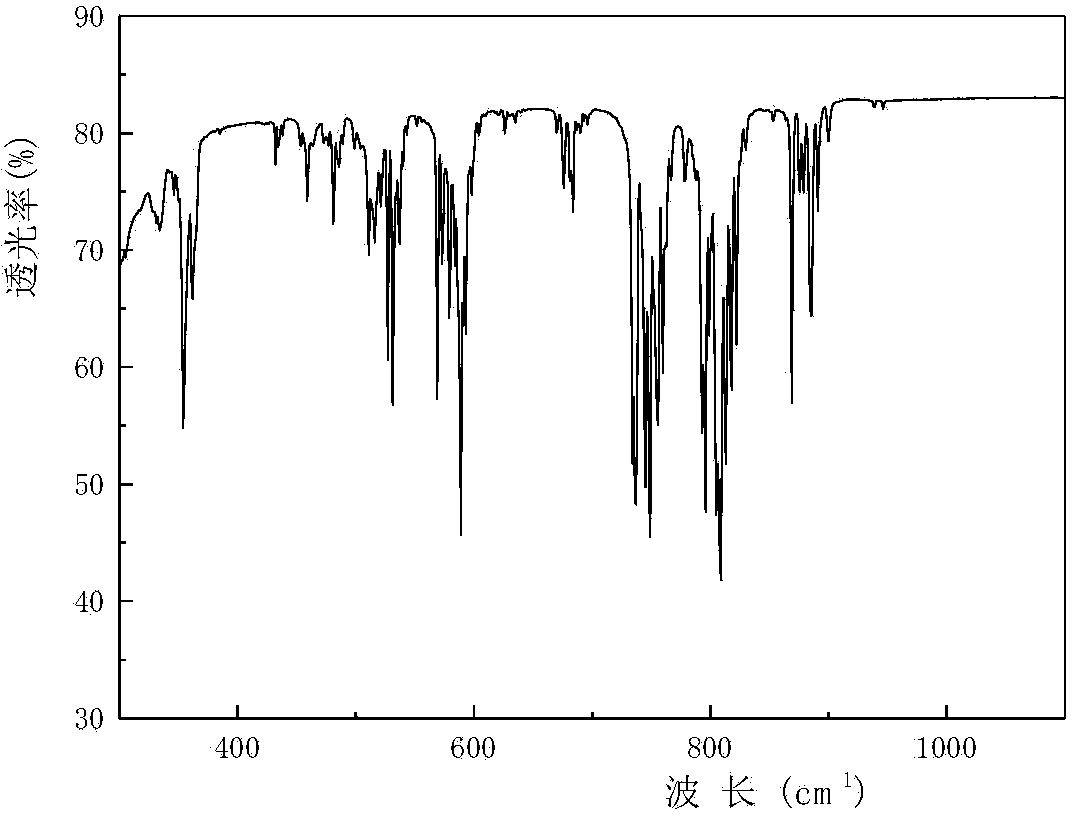

[0030] Weigh 63.36g of Y 2 O 3 , 48.16gAl 2 O 3 , 0.952gNd 2 O 3 , 0.48g of magnesium silicate mass. Add 200g of anhydrous ethanol, and 400g of alumina grinding balls, ball mill at 180r / min for 15h, after ball milling, the powder is dried, sieved, and then formed by dry pressing at 10MPa, and then cold isostatic pressing at 200MPa. The ceramic green body was sintered in vacuum at 1730°C for 10h. The linear transmittance curve of the prepared Nd:YAG ceramic with double-sided polishing and thickness of 4 mm is as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com