Method for using energy of acetic acid device

A technology of acetic acid and energy, which is applied in the separation/purification of carboxylic acid compounds, the preparation of carboxylic acid by carbon monoxide reaction, organic chemistry, etc. It can solve the problems of unreasonable energy utilization and unrecovered reaction heat, so as to improve the economic benefit of the device, The effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

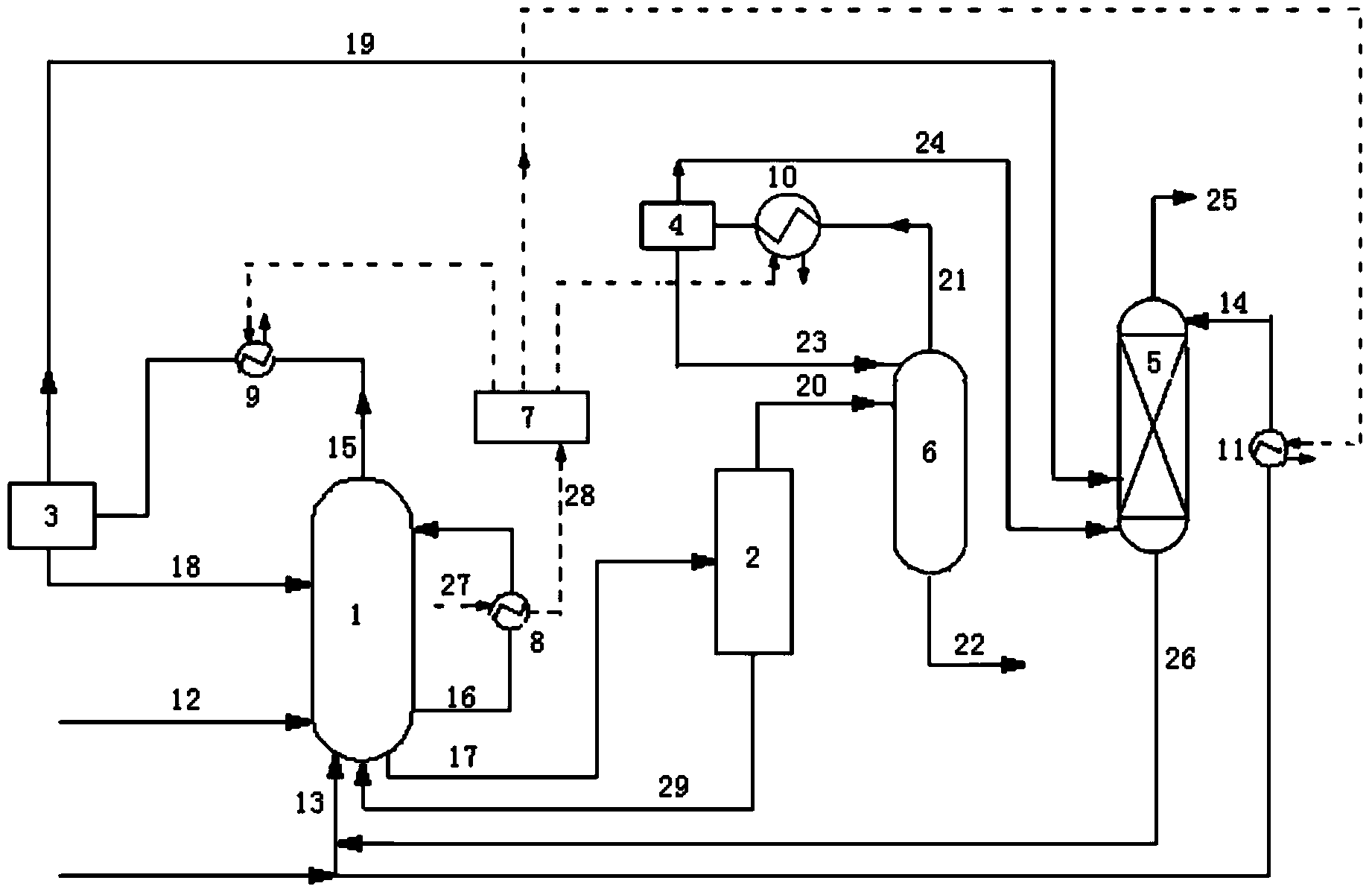

[0025] use figure 1 As shown in the flow process, carbon monoxide 12 and the first methanol 13 enter the reactor 1, and after the reaction, the top obtains a gaseous phase flow 15, and the bottom obtains a first liquid flow 16 and a second liquid flow 17; the first liquid flow 16 Return to the reactor after being cooled by the first heat exchanger 8; the gas phase stream 15 enters the first liquid separation tank 3 after being cooled by the second heat exchanger 9, and after liquid separation, a liquid phase stream 18 and a first tail gas stream 19 are obtained The liquid phase stream 18 returns to the reactor 1; the second liquid phase stream 17 enters the flash tower 2, and the flash tower top obtains the gas phase stream 20, and the bottom obtains the liquid phase stream 29; the liquid phase stream 29 returns to the reactor; The gas phase stream 20 at the top of the steaming tower 2 enters the light component tower 6, and the gas phase stream 21 is obtained at the top of th...

Embodiment 2

[0029]Same as [Example 1], taking an acetic acid plant with an annual output of 300,000 tons as an example, the feed rate of methanol is 20,000 kg / hr, the feed rate of carbon monoxide is 18,600 kg / hr, the reaction temperature is 190° C., and the operating pressure is 3.0 MPa. The oxo synthesis reactor It is necessary to remove the reaction heat of 7.1MW / hr, use the boiler and water to recover heat, generate low-pressure steam, and remove the reaction heat. The generated low-pressure steam leads to the refrigeration system to prepare chilled water. The efficiency of the low-pressure steam refrigeration system is 60-70%, and at least 4260KW / hr of cooling capacity can be recovered, as shown below:

[0030] The cooling capacity required by the second heat exchanger 9 is 283KW / hr, the cooling capacity required by the third heat exchanger 10 is 1454KW / hr, and the cooling capacity required by the third heat exchanger 11 is 180KW / hr, totaling 1917KW / hr The cooling capacity, other cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com