A kind of preparation method of epoxy polymerized soybean oil for printing ink

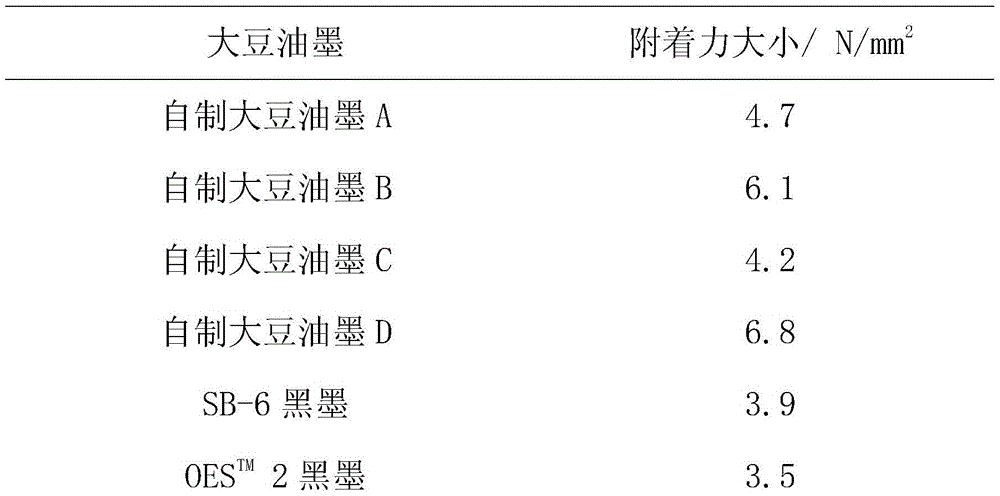

A technology based on soybean oil and epoxy, which is applied in inks, applications, household appliances, etc., can solve the problems of slow progress, low viscosity, poor adhesion, etc., and achieve the effect of stable system performance, clear imprint, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

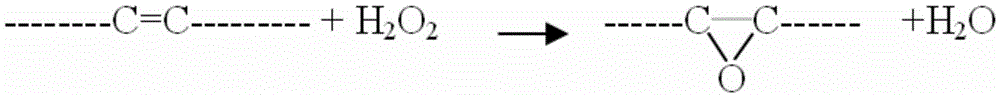

Method used

Image

Examples

Embodiment 1

[0022] A kind of epoxy polymerized soybean oil for printing ink is prepared according to the following steps:

[0023] (1) Put a certain amount of soybean oil in the reaction kettle, start stirring, and then slowly heat to 250°C, keep it warm for 30 minutes, then add a certain amount of anthraquinone, keep it warm for 2 hours, and then lower it to room temperature to obtain the polymerization crude soybean oil;

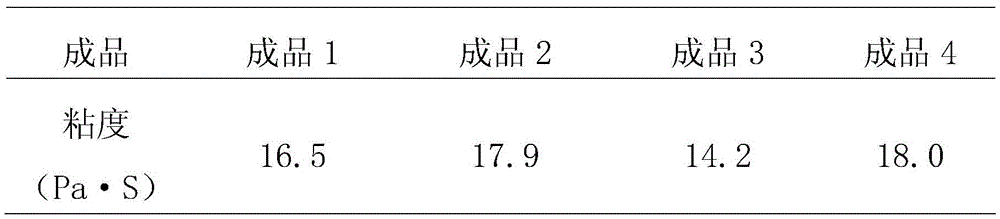

[0024] (2) Slowly raise the temperature of the polymerized soybean oil crude material at room temperature to 60°C under constant stirring, add a certain amount of ditungsten trioxide, and start to drop the hydrogen peroxide solution with a mass fraction of 30%, and control the dropwise addition The time is 1 hour, then keep warm for 5 hours, then cool to room temperature, and let it stand for 24 hours, then centrifuge at a speed of 2000r / min for 20 minutes, then collect the upper layer liquid and filter it, and the filtrate is epoxy-polymerized soybean oil product 1. ...

Embodiment 2

[0027] A kind of epoxy polymerized soybean oil for printing ink is prepared according to the following steps:

[0028] (1) Put a certain amount of soybean oil in the reaction kettle, start stirring, then slowly heat to 230°C, keep it warm for 30 minutes, then add a certain amount of pentahydroxy iron, keep warm for 2 hours, and then lower it to room temperature to obtain Polymerized soybean oil crude material;

[0029] (2) Slowly raise the temperature of the polymerized soybean oil coarse material at room temperature to 50°C under constant stirring, add a certain amount of lithium oxide, and start to drop a hydrogen peroxide solution with a mass fraction of 30%, and control the dropping time to 1h, then keep warm for 4h, then cool to room temperature, and let it stand for 24h, then centrifuge at 2500r / min for 20min, then collect the upper layer liquid and filter, the filtrate is the epoxy-polymerized soybean oil product 2.

[0030] Among them, the mass ratio of iron pentahydr...

Embodiment 3

[0032] A kind of epoxy polymerized soybean oil for printing ink is prepared according to the following steps:

[0033] (1) Put a certain amount of soybean oil in the reaction kettle, start stirring, and then slowly heat to 200°C, keep it warm for 20 minutes, then add a certain amount of anthraquinone, keep it warm for 1 hour, and then lower it to room temperature to obtain the polymer crude soybean oil;

[0034] (2) Slowly raise the temperature of the polymerized soybean oil coarse material at room temperature to 40°C under constant stirring, add a certain amount of ditungsten trioxide, and start to drop the hydrogen peroxide solution with a mass fraction of 30%, and control the dropwise addition The time is 0.5h, then keep warm for 4h, then cool to room temperature, and let it stand for 20h, then centrifuge at 1000r / min for 15min, then collect the upper layer liquid and filter, and the filtrate is the epoxy-polymerized soybean oil product 3.

[0035] Wherein, the mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com